Water Ripple Stainless Steel Sheet: Fluidity in Motion

Table of Contents

Water ripple stainless steel sheet is a masterful addition to any interior space, combining a striking visual display with the unyielding strength of stainless steel. Its unique, rippled design creates an organic and flowing feel, reflecting the movement of water across its surface. The result is a beautiful and eye-catching texture that stands out amongst more traditional decor choices. With its remarkable durability and resistance to corrosion, water ripple stainless steel sheet is the perfect material for both practical applications and purely aesthetic purposes, making it a versatile and sophisticated choice for any home or commercial environment.

What is Water Ripple Stainless Steel Sheet?

Water ripple stainless steel sheet is a type of decorative metal sheet that features a unique ripple pattern on its surface. This pattern is created through a specialized manufacturing process that involves embossing stainless steel sheets with a series of raised ripples. The result is a surface that is both tactile and visually interesting, making it a popular choice for use in both residential and commercial spaces.

Benefits of Water Ripple Stainless Steel Sheet

Unique Appearance

With its distinctive and visually appealing ripple or water wave pattern, corrugated stainless steel sheet can add texture and interest to any room. The varying depths and movement of the pattern create a sense of movement and dimension, making it ideal for feature walls or as a decorative accent.

Durability

Stainless steel is known for its durability and corrosion-resistant properties. Water ripple stainless steel sheet is no exception and can withstand exposure to moisture, heat, and chemicals, making it ideal for use in high-traffic areas such as in kitchens and bathrooms.

Easy Maintenance

Water wave stainless steel sheet is easy to clean and maintain, requiring only warm water and a mild detergent. It is non-porous and resistant to the growth of mold, bacteria, or other pathogens, making it a hygienic choice for interior spaces.

Versatility

Ripple stainless steel sheet comes in a variety of colors and finishes that can complement any design scheme. It is a versatile material that can be used in a range of applications such as feature walls, kitchen splashbacks, decorative facades, and ceilings.

Sustainability

Stainless steel is a highly sustainable material that is 100% recyclable and can be used again and again without losing its quality or properties.

Acoustic Properties

The unique texture of corrugated stainless steel sheet can also help to improve insulation and reduce noise levels. The pattern of the material helps to absorb sound waves, making it ideal for creating acoustic barriers or soundproofing walls.

Fire Resistance

Water ripple stainless steel sheet is a non-combustible material, making it an ideal choice for use in areas where fire resistance is required such as commercial kitchens or high-rise buildings.

Installation Methods of Water Ripple Stainless Steel Sheet

Glue-Up Installation

- Measure and mark the area to determine the placement of the ceiling panels before preparing the wall surface.

- Do not tear off the protective film of the water corrugated board first. Squeeze structural adhesive onto the back of the board, covering the back as much as possible with the adhesive

- Align the dimensions and attach the water ripple board to the wooden base of the ceiling.

- Carefully place each tile on the adhesive surface and gently press it down, ensuring that it is level and even.

- Continue this process until the entire area is covered, cutting tiles to fit around electrical outlets or other obstacles.

- If conditions permit, use wooden stakes to support the ceiling and floor, and wait for three to four days before removing the protective film.

Clip-On Installation

- Measure and mark the area to determine the placement of the clips before preparing the wall surface.

- Clean the wall thoroughly with warm water and a mild detergent or cleaning solution and wait for it to dry.

- Use a notched trowel to apply adhesive evenly to the backsplash area.

- Clip the edge of water ripple box into place on the clips with gentle pressure, ensuring that the tiles are level and in the proper position.

- Repeat the process, working in small sections at a time, until the entire backsplash area is covered.

- Leave a small gap between each tile to create a grout line.

- Allow the adhesive to dry completely before applying grout to fill in the gaps between the tiles.

Applications of Water Ripple Stainless Steel Sheet

Wall Decoration

The unique pattern and texture of water wave stainless steel sheets can be used to create a stunning visual effect on walls and can add a contemporary and sophisticated look to any space.

Ceiling Panels

Corrugated stainless steel sheets, also known as ripple sheets or water wave sheets, can be used to add a unique and stylish appearance to ceilings, transforming the ambiance of any room.

Furniture Design

Water wave stainless steel sheets can be used in furniture design, such as tabletops, cabinet doors, and backsplashes in the kitchen, to create a modern and sleek appearance.

Column Cladding

Ripple sheets can be used for column cladding to give a refined and modern touch to buildings' exteriors and interiors.

Elevator Decoration

Water wave sheets can also be used in elevator decoration, adding a sleek and sophisticated look to the space.

Signage

Corrugated sheets can be used for signage, especially if you're aiming to achieve a unique and modern look.

Water ripple stainless steel sheets offer a wide range of applications for designers and architects, providing countless possibilities in design. The unique patterns and textures of these sheets can transform any space into a contemporary, stylish, and sophisticated masterpiece.

How to Select Water Ripple Stainless Steel Sheet ?

Choosing the right water ripple stainless steel sheet can be a challenging task, especially for individuals without prior experience. Here are some factors to consider when selecting water ripple stainless steel sheets:

Material Quality

The quality of the stainless steel used in making the water ripple sheets determines their durability, corrosion resistance, and strength. It is essential to choose high-quality stainless steel sheets to ensure they can withstand the environmental conditions and provide long-lasting performance. You need to consider whether the usage location is indoor or outdoor, whether the local climate is rainy all year round, and so on. There are some stainless steel grades for options. 201#,304# or 316#.

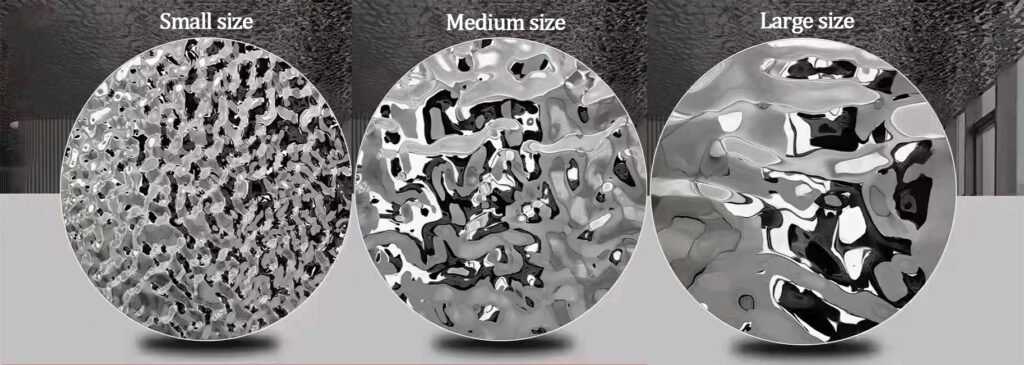

Pattern Design

The pattern design on the water ripple stainless steel sheets determines the overall aesthetic value and visual appeal. You must choose the appropriate pattern and design that complements the desired décor, ambiance, and interior design that you want to achieve. There are small ripple size, medium, large, and flowing ripple etc.

Sheet Thickness

The thickness of the water ripple stainless steel sheet determines its weight, durability, and performance. Thicker sheets are more durable and provide improved resistance to damage, corrosion, and impact. When choosing a sheet, consider the application, and select the appropriate thickness that will meet your requirements. If the thickness is too large and the board is too heavy, it will bring difficulty to installation. JYF Metal suggest that you choose within the thickness range of 0.6-0.8mm.

Sheet Size

The size of the water ripple stainless steel sheet determines how much space it can cover. You must measure the area you want to cover and choose the appropriate sheet size that will fit that space. The general size are 1000*2000mm/ 1220*2440mm/ 1220*3050mm/ 1500*3000mm

Surface Finish

The surface finish of the water ripple stainless steel sheet can vary and can be a factor to consider, depending on the environment and application. Some common surface finishes include polished or brushed and different colors. You should choose the finish that best complements your desired aesthetic value and ambient atmosphere.

Cost

Lastly, you must consider the cost of the water ripple stainless steel sheet. The cost will vary depending on the material, quality, pattern design, thickness, size, and surface finish. You should have a budget in mind and choose a sheet that meets your requirements and fits your budget.

In Conclusion

Choosing the right water ripple stainless steel sheet requires considering factors such as material quality, pattern design, sheet thickness, sheet size, surface finish, and cost. By keeping these factors in mind, you can select the appropriate sheet that meets your needs and provides the desired aesthetic value.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions