Say Goodbye to Smudges with Anti-Fingerprint Process

Table of Contents

Stainless steel is a popular material choice for numerous applications due to its durability, strength, and corrosion resistance. It is commonly used for decorative purposes in various industries, including architecture, interior design, and home appliances. However, the surface of stainless steel is prone to fingerprints, which can easily accumulate dirt and other contaminants and reduce the material’s aesthetic value. To address this issue, an anti-fingerprint process has been developed, which involves treating the surface of decorative stainless steel sheets to prevent the accumulation of fingerprints and other marks. In this article, we will discuss in detail the anti-fingerprint process of decorative stainless steel sheets.

Stainless steel sheets are available in numerous styles, patterns, and finishes, making them a popular choice for decorative applications. The material is resistant to oxidation, rust, and other forms of corrosion, making it ideal for use in harsh environments. Stainless steel sheets’ surface can be treated using various methods, such as polishing, brushing, or etching, to create unique textures and patterns. However, the surface of stainless steel sheets is susceptible to fingerprints, which can reduce their aesthetic appeal and make them challenging to maintain.

Problems With Fingerprints on Stainless Steel Sheets

Fingerprints on stainless steel sheets can accumulate dirt, grease, and other contaminants, making them difficult to remove. This can result in a buildup of grime, which can make the surface of the stainless steel sheet look unclean and diminish its aesthetic value. In addition, cleaning the surface of the stainless steel sheet can be challenging, as the material is susceptible to scratches and other types of damage. This can further reduce the sheet’s aesthetic value and affect its functionality.

Anti-fingerprint Process of Decorative Stainless Steel Sheet

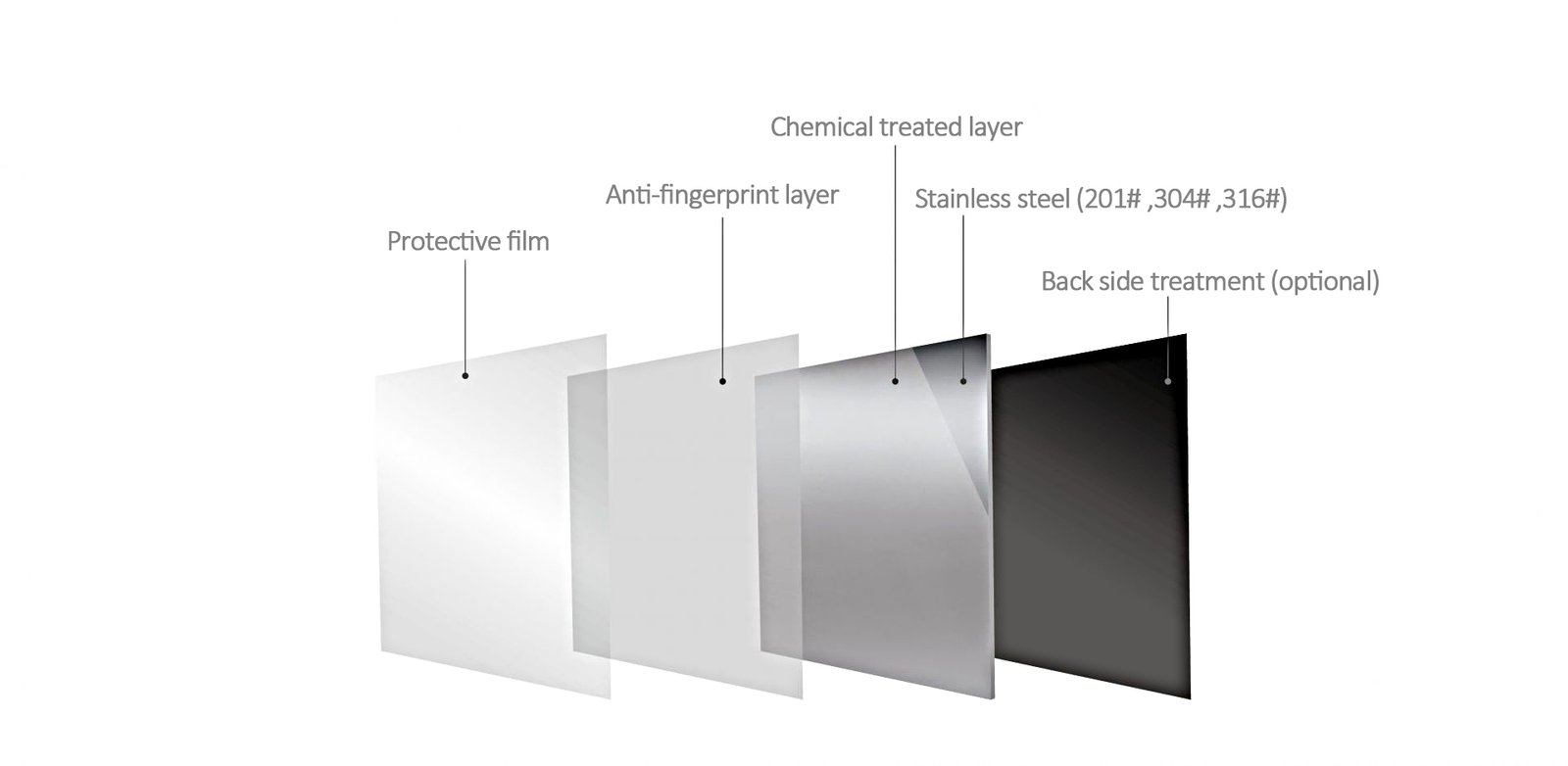

The anti-fingerprint process of decorative stainless steel sheets is designed to address the problem of fingerprints on the material’s surface. The process involves treating the surface of the stainless steel sheet with a special coating or film that makes it resistant to fingerprints. The coating or film fills the pores on the surface of the sheet, making it more difficult for fingerprints to adhere to the material. As a result, the surface of the sheet remains clean and free of prints, resulting in a more attractive appearance.

Types of Anti-fingerprint Process

There are various types of anti-fingerprint processes used to treat the surface of decorative stainless steel sheets. Some of the most common methods include:

Nano-coating

Nano-coatings involve the application of microscopic particles onto the surface of the stainless steel sheet. The particles fill the pores on the surface, making it more difficult for fingerprints to adhere to the material. These coatings are transparent, making them ideal for use on decorative stainless steel sheets.

Among the various types of anti-fingerprint coatings, nano-coating is a popular option due to its transparency and effectiveness. The nano-coating process uses very small particles to create a protective layer on the surface of the stainless steel sheet that prevents fingerprints from sticking to the material. These particles, typically less than 100 nanometers in size, fill the pores on the surface of the stainless steel sheet, creating a hydrophobic barrier that makes the surface more resistant to fingerprints.

Nano-coating is a highly effective process for anti-fingerprint stainless steel sheet since it does not affect the material's appearance or texture while providing optimal protection. This process does not impact the color or pattern of the stainless steel sheet, ensuring that the material retains its original appeal.

Polishing

Polishing the surface of the stainless steel sheet can also reduce fingerprints. The polishing process involves using a special abrasive material to smooth the surface and fill any pores, making it more difficult for fingerprints to adhere to the material.

Chemical Treatment

Chemical treatment involves the use of special chemicals to treat the surface of the stainless steel sheet. The chemicals react with the material, forming a protective layer that makes it more difficult for fingerprints to adhere to the surface.

Process of Nano-coating

The process of applying nano-coating to stainless steel sheet varies, but typically involves the following steps:

Cleaning the Surface: The surface of the stainless steel sheet is cleaned thoroughly to ensure that no dust, dirt, or other contaminants remain.

Pre-treatment: Before the nano-coating is applied, the surface of the stainless steel sheet is treated with a pre-treatment solution to ensure proper adhesion between the coating and the material.

Nano-coating: After pre-treatment, a special solution of nanoparticles is applied to the surface of the stainless steel sheet. The solution is typically applied using a simple spray-on or dip-coating process.

Curing: Once the nano-coating is applied, the stainless steel sheet is cured or dried at a specific temperature to ensure that the nano-particles adhere to the material.

Pros & Cons of Anti-fingerprint Process

Prons

Improved Aesthetic Value: Anti-fingerprint processes can significantly improve the aesthetic value of decorative stainless steel sheets. By preventing fingerprints from accumulating on the surface of the sheet, the material remains clean and attractive.

Easy to Clean: Anti-fingerprint decorative stainless steel sheets are easier to clean as the material does not accumulate dirt and other contaminants. This makes the material more hygienic and easier to maintain.

Long-Lasting: The anti-fingerprint process can make decorative stainless steel sheets more durable and long-lasting. The material is more resistant to scratches, corrosion, and other types of damage, resulting in a longer lifespan.

Cost-effective: Using anti-fingerprint processes on decorative stainless steel sheets can be cost-effective in the long run, as the material requires less maintenance and lasts longer.

Cons

Limited Effectiveness: Some anti-fingerprint processes are not 100% effective, and fingerprints may still be visible on the surface of the sheet to some extent.

Higher Cost: Anti-fingerprint processes can add to the cost of decorative stainless steel sheets, making them more expensive than untreated sheets.

Limited Variety: Some anti-fingerprint coatings may limit the variety of patterns and textures that can be applied to the surface of the sheet. This can limit the design choices available to architects and designers.

Conclusion

The anti-fingerprint process of decorative stainless steel sheets offers numerous advantages and can significantly improve the material’s aesthetic value. The process involves treating the surface of the sheet with a special coating or film that prevents fingerprints from accumulating on the material. The anti-fingerprint process of decorative stainless steel sheets can be achieved through various methods, including nano-coatings, polishing, and chemical treatments. However, it is essential to carefully consider the advantages and disadvantages of each method and choose the most appropriate option based on the specific application requirements.

The anti-fingerprint process of decorative stainless steel sheets can help to ensure that the material remains clean, attractive, and functional for years to come. This technology has enabled architects and designers to use stainless steel sheets in a wider range of applications, including high-traffic areas where the material may be prone to fingerprints and other types of contamination. By reducing the maintenance requirements of stainless steel sheets, the anti-fingerprint process has made this material an increasingly popular choice across various industries.

Everyone should consider the anti-fingerprint process of decorative stainless steel sheets to enhance the aesthetic value of their decorative applications. The process can improve cleanliness, reduce maintenance and repair costs, and protect the material from damage or wear and tear in high-traffic areas.

You Might Also Like

Please Share This

Recent Posts

Follow Us On Twitter

On-site Installation of Stainless Steel Screen Partition

Precision-made. Professionally installed.

Transforming spaces with durable, elegant metal dividers.

📩 DM us for custom design and project support.

#roomdivider #screenpartition #metalmesh #metalpartition #metalcustom

On-site Installation of Stainless Steel Screen Partition

Precision-made. Professionally installed.

Transforming spaces with durable, elegant metal dividers.

📮DM us for custom design and project support.

#interiordecoration #metalpartition #roomdivider #sheetmetalfab

Café Design | A Sensory Collision of Metal and Coffee

This design is from BOUNDLESS SPACE DESIGN OFFICE

If you are interested in stainless steel decorative materials, please contact me for a quote !

Email: claire@jyfmetal.com

#interiordecoration #decorativematerials #metallic