Shine Bright with Mirror Stainless Steel Sheet

Table of Contents

Mirror stainless steel sheet is one of the most popular finishes of stainless steel. Recognizable for its high reflectivity and outstanding aesthetics, it is an ideal material for various applications in architecture and design. In this article, we will discuss what mirror stainless steel sheet is, how it is produced, the different polishing levels, its applications, and its advantages and disadvantages.

What is Mirror Stainless Steel Sheet?

Mirror stainless steel sheet is a highly reflective, polished finish that resembles a mirror. The process of polishing stainless steel to achieve a mirror finish involves grinding and polishing the surface repeatedly with progressively finer abrasives. The resulting surface is exceptionally smooth, flat, and reflective. The quality of the mirror effect depends on the polishing process and the grade of the stainless steel used.

How is Mirror Stainless Steel Sheet Produced?

Mirror stainless steel sheet is produced by improving the surface finish of stainless steel through a series of grinding, polishing, and buffing processes. The process starts with grinding using coarse abrasive grit to remove any surface defects, scratches, or other imperfections. The stainless steel is then polished with successively finer grit abrasives until the desired level of shine is achieved. Finally, the steel is buffed using a polishing compound and a fine cloth to produce an ultra-smooth, highly polished, mirror-like finish.

Polishing Levels of Mirror Stainless Steel Sheets

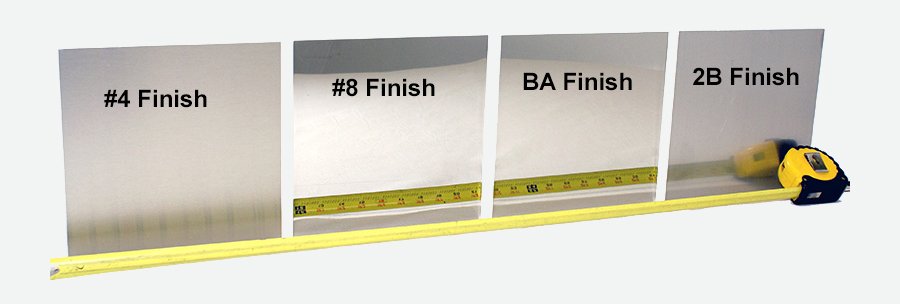

There are several different polishing levels used to achieve the reflective surface in mirror stainless steel sheets. The most common polishing levels are:

4K Finish – This is a mirror finish with an average roughness (Ra) of approximately 0.25 microns. The surface appears to have imaginative satin patterns, but the patterns are finer than satin patterns

8K Finish – This is a super-mirror finish with a roughness average (Ra) of around 0.1 micrometers, providing a higher level of reflectivity than both 4K and 6K finishes.

BA Finish – This is a bright annealed finish that provides a highly reflective surface with a smooth, mirror-like finish. The polish level is typically a 180-grit.

Reflection Effects of Different Polishing Levels

The polishing level directly affects the reflection quality of mirror stainless steel sheets. Higher polishing levels generally result in a more reflective surface. For example, with a 4K finish, the reflection will appear somewhat hazy with some graininess visible. In contrast, an 8K finish will provide a super mirror finish that produces a clear and crisp reflection with very little graininess or haze. At even higher polishing levels, such as super polishing, the reflection will be even clearer and more uniform.

Applications of Mirror Stainless Steel Sheet

Architectural Interiors

Mirror stainless steel sheets are frequently used to enhance the aesthetic appeal of architectural interiors. They can be incorporated into wall cladding, columns, and elevator interiors for a sleek and modern finish that reflects light and creates the illusion of more space.

Decorative Features

Mirror stainless steel sheets are a popular choice for decorative applications. They can be cut into various shapes and sizes to create beautiful sculptures and art installations.

Industrial Applications

Mirror stainless steel sheets are frequently used in industrial settings where a reflective surface is required, such as in mirrors for optical equipment, scientific instruments, and laser technology.

Automotive Design

Mirror stainless steel is frequently used in automotive design for its high reflectivity and resistance to scratching. It is often used for car accents, such as hubcaps, trims, and grilles.

Medical Equipment

Mirror stainless steel is used in medical equipment such as surgical instruments and dental tools due to its durability and resistance to corrosion.

Kitchen and Bathroom Accents

Mirror stainless steel sheets are commonly used in kitchen and bathroom designs for backsplashes and countertops due to their reflective properties, scratch resistance, and easy maintenance.

Jewelry and Fashion Accessories

Mirror stainless steel can be used in the design of jewelry and fashion accessories such as watches, bracelets, and earrings for a modern and sophisticated look.

Pros & Cons of Mirror Stainless Steel Sheet

Pros

Durability: Stainless steel is known for its exceptional strength and resistance to corrosion, making mirror stainless steel sheets highly durable, low maintenance and long-lasting.

Hygienic: The smooth surface of the mirror stainless steel sheets does not allow bacteria to adhere to it, making them ideal for use in sanitary and medical environments.

Versatile: Mirror stainless steel sheets come in a range of colors and finishes, allowing for a customizable design that can work with any style.

Cons

Scratches: The reflective surface of mirror stainless steel sheets is prone to scratches, which can be challenging to fix.

Water spots: Mirror stainless steel sheets are prone to water spots. Due to the highly reflective nature of the surface, any water droplets or moisture left on the sheet can leave visible marks or spots once they evaporate. This can affect the overall appearance of the stainless steel and may require regular cleaning and maintenance to keep it free from water spots.

In Conclusion

Mirror stainless steel sheet is a popular and highly versatile material with extensive use in various architectural, industrial and decorative applications. The high reflectivity and polished finish of mirror stainless steel sheets offer a sophisticated look and exceptional durability. The customizable finishes and colors accommodate any style and design preferences. However, it is essential to consider the disadvantages such as scratches and fingerprints while choosing the material for a particular application. Overall, mirror stainless steel sheets are a highly desirable material in modern design with many advantages and few disadvantages.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions

Bessy Zheng

" Successful collaboration begins with listening and trust. "

Email: bessy@jyfmetal.com