Decorative Stainless Steel Sheets in Architectural Design

Table of Contents

Stainless steel has long been a popular material in architecture and design. It is durable, easy to maintain, and has a modern look that can be applied to both interior and exterior spaces. Decorative stainless steel sheets take this versatility to the next level, offering architects and designers an array of customizable options to enhance the aesthetics of their projects.

Decorative stainless steel sheets are steel sheets that have been processed to produce unique textures, designs, and finishes. The sheets can come in various sizes and thicknesses, and a wide range of finishes can be applied to the surface of the steel. The most common finishes include mirror, brushed, sandblasted, embossed, etched, PVD-coated and perforated, etc. These finishes provide architects with an endless array of design options, making stainless steel one of the most popular materials for creating visually appealing designs.

What Finishes Can Be Made ?

Mirror Stainless Steel Sheets

Mirror finish stainless steel sheet is produced by using the No. 8 process, which is a highly precise, multi-step process that polishes the surface of the stainless steel until it resembles a mirror. The process involves the use of progressively finer abrasives to polish the steel to a high shine. The final step is buffing with a polishing compound to produce the mirror-like finish. The resulting product has an extremely smooth, reflective surface that is free from any visible imperfections.

Mirror stainless steel sheet offers a range of benefits that make it an attractive choice for architects, designers, and builders. The highly reflective surface catches and reflects light, creating an illuminating effect that can increase the visual appeal of any space. The smooth surface is also easy to clean and maintain, making it an excellent choice for high-traffic areas. Additionally, its non-porous surface means that it won't stain, corrode, or tarnish, making it a highly durable and long-lasting material.

Brushed Stainless Steel Sheets

Brushed stainless steel sheet (Hairline stainless steel sheet / HL) is produced by a process called passivation. The stainless steel sheet is first cleaned with a degreasing agent to remove any dirt or oils. Then the sheet is mechanically polished with an abrasive material, often in the form of a belt, to create the trademark parallel lines. The polish can be adjusted to produce a wide range of textures and finishes, from coarse to fine.

Hairline stainless steel sheet has a unique texture that sets it apart from other stainless steel finishes. The surface of the metal is polished with a fine abrasive material, leaving behind a series of parallel lines. The brush marks produce a soft, reflective sheen that adds a contemporary and stylish dimension to the metal. The brushed finish also hides scratches and marks better than a mirrored finish, making it a popular choice for high-traffic areas.

Sandblasted Stainless Steel Sheets

Sandblasting is a surface treatment that involves using highly compressed air or water to force abrasive particles onto the surface of the stainless steel. The sandblasting process for stainless steel sheets involves the use of a sandblasting machine, which forces abrasive particles, such as sand or glass beads, onto the surface of the metal. The size of the abrasive particles can be varied to produce a range of textures, from a fine texture to a more ridged, rugged finish.

Sandblasting creates a pattern of tiny divots or "pits" on the surface of the steel, producing a unique texture and aesthetic. The texture is more subtle than with brushed or polished finishes, but it still adds a distinct look and feel to the metal.

Pvd-Coated Stainless Steel Sheets

The PVD coating process used on stainless steel sheets involves vaporizing a cathode of the coating material (such as titanium, zirconium, chromium, etc.) in a vacuum. The vapor then forms a thin layer of the material on the stainless steel sheet's surface, altering its physical and chemical properties. The PVD process uses ion-plating technology to achieve exceptional coating durability and flexibility. The coating thickness can also be controlled to achieve the desired color and finish of the PVD coated stainless steel sheets.

PVD coating is a process where a thin layer of a high-performance coating is applied to stainless steel sheets which enhances their appearance and performance. The coating is a type of vacuum deposition process where plasma energy is used to form a thin film of the coating that has a thickness of around 0.3 microns. The PVD coated stainless steel sheets come in an array of colors which lend to the design and style preferences.

What Patterns Can Be Made ?

Embossed Stainless Steel Sheets

The production of embossed stainless steel sheets involves a specialized stamping or pressing process to create the raised patterns. A sheet of stainless steel is placed between a patterned die or roller and a hydraulic press, which applies pressure to the metal to create the desired relief design. The embossed pattern can then be finished with a range of surface treatments, including polishing or brushing, to achieve the desired texture or appearance.

Embossing is a technique used to produce a raised pattern on the surface of stainless steel. The process involves stamping or pressing the metal with a patterned die or roller, which creates a relief image on the surface. There is a wide range of embossed patterns available, including hexagonal, diamond, and floral designs, which can add a unique texture to the metal. Embossed stainless steel sheets are typically available in a range of thicknesses, finishes, and colors, allowing for a completely customizable appearance. Water ripple stainless steel sheet is most popular, and it is used for wall or ceiling decoration.

Etched Stainless Steel Sheets

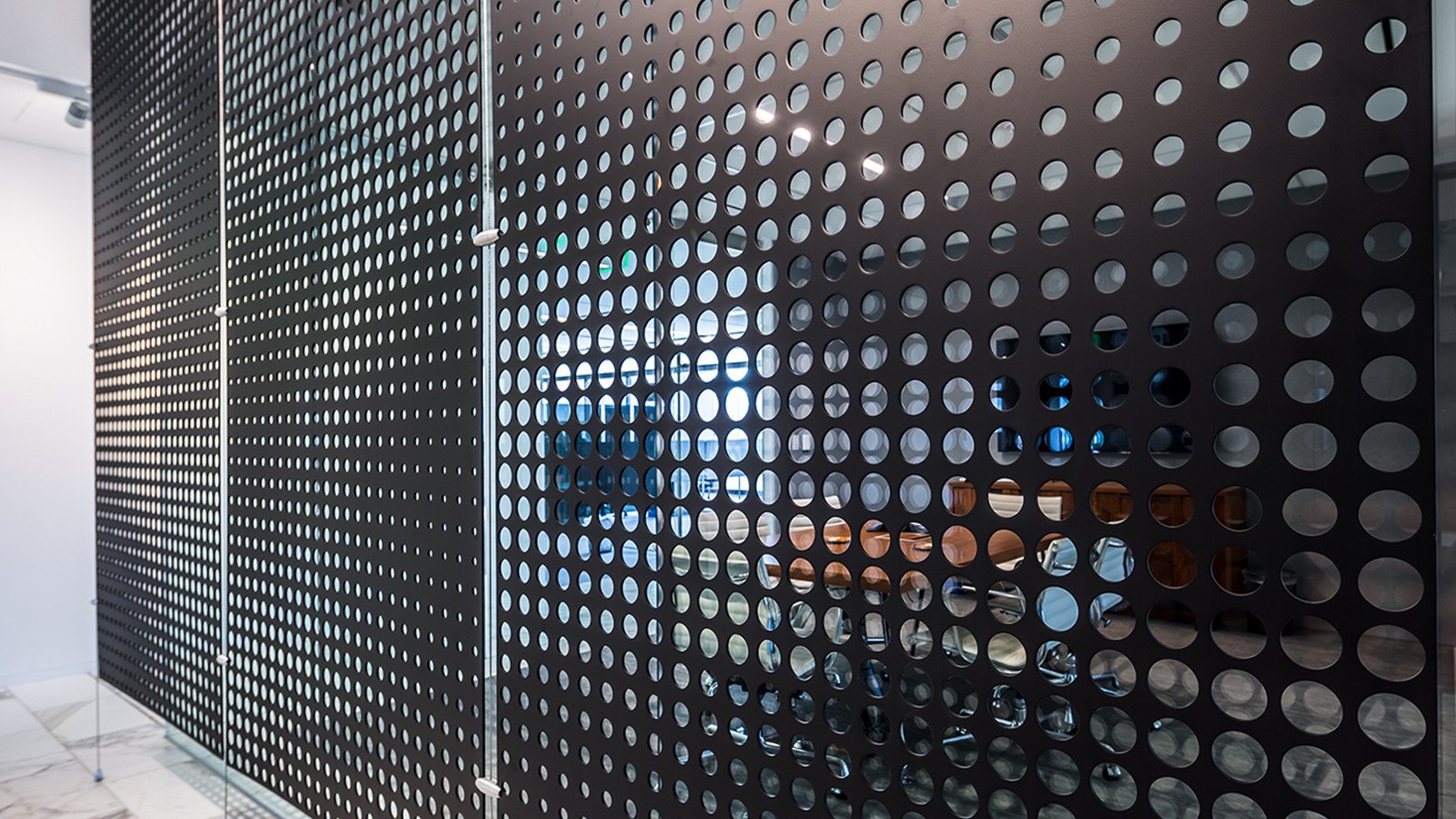

The production of perforated stainless steel sheets involves a specialized punching process. A sheet of stainless steel is placed between a punch and a die, and the punch is then forced through the metal, creating a perforation. The pattern of the perforations is precisely controlled and can be customized to specific design requirements for airflow, light diffusion, or soundproofing.

Perforated stainless steel sheets are sheets of stainless steel with a pattern of holes or perforations punched into the metal. The perforations can be circular, hexagonal, square, or any other shape. Perforated stainless steel sheets come in various hole sizes and shapes, which allows designers to achieve specific airflow, light diffusion, or soundproofing requirements. The sheets can also be finished with a range of surface treatments, including a brushed or polished finish.

Perforated Stainless Steel Sheets

The production of etched stainless steel sheets involves a specialized process where a sheet of stainless steel is coated with a resist layer to protect the areas that should not be etched. The desired design is then printed onto the resist layer, which is then etched using a chemical, a laser, or an electrolytic process. The resist layer is then removed, leaving behind the desired pattern on the surface of the stainless steel.

Etching is a technique used to produce an image or design onto the surface of stainless steel. The process involves using a chemical or a laser to remove material from the surface in a controlled way, creating a textured pattern or design. Etched stainless steel sheets offer a unique visual interest to the metal, allowing designers to create customized detailed images, logos, or designs on the surface of the steel. The texture can range from light surface etching to deep-grooved patterns, offering a range of finishes and styles.

Applications of Decorative Stainless Steel Sheets

Decorative stainless steel sheets find applications in various industries like architecture & construction, automotive, aerospace, and energy. Architects and designers use decorative stainless steel sheets in:

Decorative stainless steel sheets are used as facade cladding to enhance the visual appeal of the building.

Decorative stainless steel sheets are used as column covers to add a modern and stylish look to the structure.

Decorative stainless steel sheets are used as feature walls to add depth and texture to the interior of buildings.

Decorative stainless steel sheets are used in the interiors of elevators to add a contemporary touch.

Decorative stainless steel sheets are used in signage to create a lasting visual impression.

Benefits of Decorative Stainless Steel Sheets

Durability: Stainless steel is a highly durable material that can withstand harsh environmental conditions, extreme temperatures, and fire. As a result, decorative stainless steel sheets are ideal for use in high-traffic areas such as airports, hospitals, and commercial buildings.

Corrosion Resistance: Stainless steel is highly resistant to corrosion, rusting, and staining. This makes decorative stainless steel sheets a perfect material to be used in areas where moisture is a problem.

Aesthetics: Decorative stainless steel sheets provide numerous customizable design options for architects and designers. The sheets can be etched or embossed with patterns, or they can be finished with various textures and colors, creating a unique visual impact of a space.

Easy Maintenance: Decorative stainless steel sheets are relatively low maintenance compared to other decorative finishes. They can be cleaned easily with mild soap and water, and their inherent durability means they are less susceptible to damage from routine cleaning.

Sustainability: Stainless steel is an environmentally friendly material as it is 100% recyclable, making it an excellent choice from a sustainability perspective.

Versatility: Decorative stainless steel sheets are suitable for numerous applications. They can be used for interior and exterior cladding, elevator interiors, column covers, wall panels, and many other decorative features in architectural design.

Increased Value: The unique visual impact and functionality of decorative stainless steel sheets add to the overall value of the architectural design. They create a sophisticated and modern aesthetic while providing functional benefits to the building.

In Conclusion

Decorative stainless steel sheets are a versatile and innovative material that can add value and beauty to any architectural and design project. The availability of various finishes, patterns, and sizes makes decorative stainless steel sheets an excellent choice for those who want to create a modern and sophisticated space that reflects their unique style and vision. Architects and designers can use decorative stainless steel sheets for a variety of applications, from exterior cladding to interior walls and ceilings, and creating an extraordinary design that is both functional and visually appealing.

Stainless steel decorative sheets are an excellent choice for architectural design. They offer numerous benefits in terms of functionality, durability, aesthetics, and sustainability, which increase the value of the building. The unique customizability and design options available with decorative stainless steel sheets allow for beautiful, functional, and distinctive design elements that give architectural projects a modern, sophisticated visual appeal.

You Might Also Like

Please Share This

Claire Leung

" Stainless steel is not only the material, but also the embodiment of the art of engineering."

Email: claire@jyfmetal.com