Explore the Versatility and Beauty of Stainless Steel Water Ripple Sheets

Table of Contents

Have you ever entered a room and been immediately captivated by how light reflected from the surfaces of walls or ceilings? Such is an astonishing innovation in the form of stainless steel water ripple sheets. These beautiful metal panels have a very contemporary look; they give a feeling of richness to any building; they also have the amazing quality of reflecting light in a truly dynamic way. Not only do they look great, but imperial sheetings are built to be heavy-duty and last, and that is why architects and designers favor them so much.

They are everywhere, from hotel foyers to restaurants and other fashionable areas. But what sets them apart from the common class of snakes? How are they made, and in what applications can they be applied? Let’s immerse ourselves in the exciting world of such appealing types of metal sheets and find out why they are so popular in contemporary design.

What are the Stainless Steel Water Ripple Sheets ?

For a casual observer, the water ripple stainless steel sheet appears to be a shiny metal foil, which has been lightly waved or rolled to give an impression of ripples in water after a stone has been dropped in. This water ripple stainless steel texture is very stylish and lit, and adds the feeling of flowing water to any room.

Key Features:

Materials: These sheets are associated with three categories namely: SS201, SS304, and SS316, with SS201 providing relatively less strength than SS304 but lesser resistance to corrosion than SS316.

Color Availability: They come in silver, gold, rose gold, black, blue, and many other colours to suit the kind of atmosphere that a homeowner has in mind.

Reflective Properties: In addition to its exterior style, its surface also has a function to illuminate the room by reflecting light.

These ripple stainless steel sheets may fit perfectly in both contemporary and traditional categories, and they look perfectly placed in any interior design.

Manufacturing Process

It is possible to wonder how these beautiful sheets acquire these pleasing textures. It is a blend of artistry and engineering or, rather, a combination of professionalism and innovation.

Material Selection – The first step is selecting the appropriate type of stainless steel for the given utilization and usage, which should be strong and reasonable in price.

Grinding and polishing – This stage makes the surface of the artifact smooth and improves its capacity to reflect light.

Embossing – The additional information states that the sheet features the water ripple stainless steel pattern through embossing, and high-precision machinery gives the sheet its characteristic look.

Color Coating – This is where color coating through PVD coating or waterplating gives the sheets their final colours, from gold to black.

Quality Control – All the sheets receive the best quality test to ensure that they meet the recommended quality before they are shipped.

Before the water ripple metal sheet is used in a structure, it undergoes several processes till it gets to the point that it is not only ornamental but also tough and durable.

Applications and Uses

Well, where and in what do people employ these captivating water ripple stainless steel sheets? The answer: just about anywhere! Their surface is matt, and their glossy appearance makes them suitable for business and home uses.

Ceilings – If you want your room to look more vast and spacious, the best thing you can do is cover it with ceiling sheets. These sheets can reflect light, enhancing the general beauty of the rooms.

Walls & Partitions – To make one’s house stand out, why not have the walls textured so as to gel well with any wonderful picture that may be hung on it? The ripple on water stainless metal gives it a character and elegance.

Hotel Lobbies & Reception Areas – A first impression that sets the first tone in our diverse lives. That is why various luxury hotels utilize water wave stainless steel panels to construct an appealing entrance and a portion of the building.

Restaurants & Cafés – Many people spend more time eating places, and therefore, the feel of the place has to be good. The appropriate lighting choice, as well as a ripple stainless steel sheet, can turn any environment into luxurious.

Custom Furniture – Think bar counters, tabletops, and decorative panels. These sheets are just an element of elegance that has been introduced in modern furniture.

The product is used in everything from offices and other business premises to stylish houses and apartments.

Benefits of Stainless Steel Water Ripple Sheets

Decorative as the shelves may seem, these shelves possess a number of benefits that include:

Durability: These sheets are produced using the best stainless steel and thus do not corrode, heat, or even when exposed to some impact.

Easy to Clean: They do not require any high level of washing since a few wipes with a wet wipe will make them look so fresh.

Reflective surface: They reflect light, hence cutting down the need for supplementary lighting in an area.

Recyclable Material: The sheets are produced with stainless steel, which is a recyclable material, making them an environmentally friendly option.

Versatile: They come in various colors and materials and can be finished in many ways in order to fit a given design idea.

These water ripple metal sheets can be used in eateries, households, or even in business premises and are not just elegant but functional as well.

Installation Guide

If you plan to use the stainless steel water ripple sheets for a project, it will be a wise decision. Here are the easy steps to a successful installation.

Step-by-Step Installation Process:

Surface preparation – The wall, ceiling or furniture, if you are going to mount it should be clean and dry as well as be even.

Measure and Cut – The sheets have to be measured correctly and sometimes laser cutter is used to modify to some size.

Fixing the Sheets – If possible, on the carcass designs, apply industrial adhesive, or screws or brackets that may be used in fixing the sheets.

Sealing & Finishing – Apply sealer to prevent moisture from seeping into the surface, and apply polish or wax to make the surface as shiny as possible.

This way, there will be no fuss when arranging it, and it will have a professional finish that will not fade soon.

Why Choose JYF Metal for Stainless Steel Water Ripple Sheets ?

For any need regarding water ripple stainless steel sheets, JYF Metal is the best at offering high-quality stainless steel products.

What Sets Us Apart ?

Quality Materials: We use SS201, SS304, and SS316. Hence, quality materials enable us to withstand high levels of strength.

Custom Finishes: Let’s face it, nothing like having mirrors, brushed, gold, black, etc., you wish for it; it is here with us.

Used by Designers & Architects: This pack of water ripple stainless steel textures has been used in many top projects worldwide.

Conclusion

Stainless steel water wave sheets are not only aluminum sheets but have become a symbol of modern looks. They are favored among designers and architects because they can reflect light, divide depth, and add aesthetics.

These sheets are perfect for residential, commercial or retail application whether it is in restaurants, hotels or for your own home. Ready to transform your space?

For more information, visit Now to get all info on stainless steel water ripple sheets at JYF Metal!

FAQs About Stainless Steel Mirror Sheets

What thickness options are available for stainless steel ripple sheets ?

Stainless steel ripple sheets typically range in thickness from 0.5mm to 3.0mm. For most interior applications, such as wall decoration or kitchen backsplashes, a thickness of 0.6mm to 1.0mm is recommended for optimal durability and ease of installation.

What are the standard sizes for stainless steel water wave sheets ?

The most common standard sizes are 4×8 feet (1220x2440mm) and 4×10 feet (1220x3050mm). However, custom sizes can be produced to meet specific project requirements.

How can I request samples ?

We provide samples to help you evaluate the surface finish and reflectivity. Sample sizes are typically 200x200mm*or 300x200mm. Please note that samples are for surface finish reference only and may not reflect the exact thickness of the final product.

Can these sheets be customized ?

Yes, stainless steel water ripple sheets can be given dimensional specifications such as size, thickness, color, and surface finish in conformity to relevant design requirements. Their ability to adjust to many different settings also makes them suitable for application in all forms of architecture.

What is the lead time for custom stainless steel water ripple panels orders ?

Lead times vary depending on the complexity of the order, including size, thickness, finish, and quantity. Typically, custom orders take 7-10days for production and delivery. Contact us for a precise timeline based on your project requirements.

How are these sheets installed ?

There are several possible ways of installing the devices depending on the intended use and appearance. Some of the common methods include adhesive or glue known as glue-up, mechanical fastening that uses clips and other forms of fixation which do not use grout. Each of them has its strengths, and they are used in projects depending on their character.

Are these sheets fire-resistant ?

Yes, water ripple stainless steel sheets are fire retardant and as such, they can be used in any areas that require fire rating like in areas that are highly susceptible to fire outbreaks such as the kitchen and in buildings with many stories.

You Might Also Like

Please Share This

Follow Us On Twitter

On-site Installation of Stainless Steel Screen Partition

Precision-made. Professionally installed.

Transforming spaces with durable, elegant metal dividers.

📮DM us for custom design and project support.

#interiordecoration #metalpartition #roomdivider #sheetmetalfab

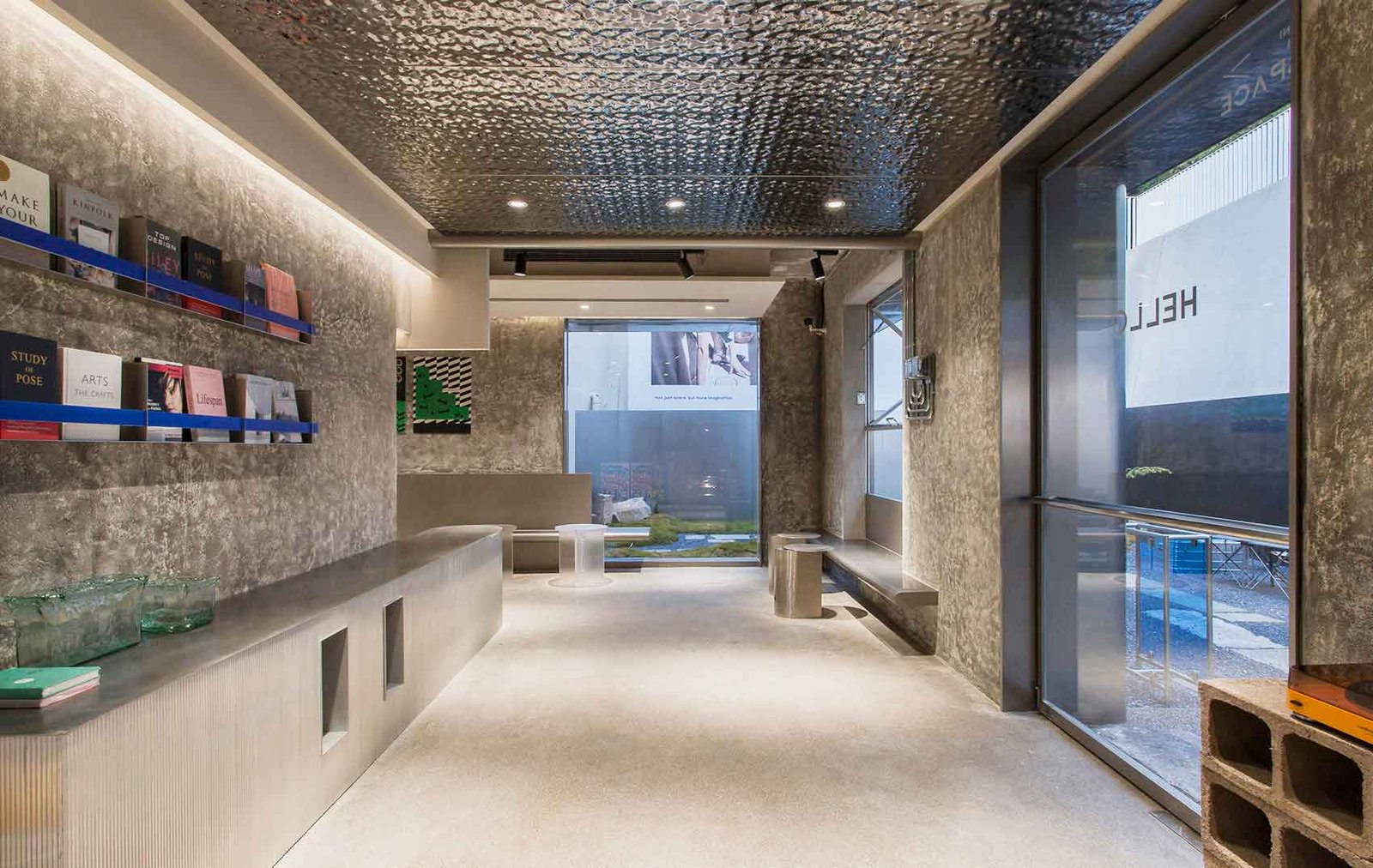

Café Design | A Sensory Collision of Metal and Coffee

This design is from BOUNDLESS SPACE DESIGN OFFICE

If you are interested in stainless steel decorative materials, please contact me for a quote !

Email: claire@jyfmetal.com

#interiordecoration #decorativematerials #metallic

Stainless Steel Fluted Panels & Skirting Boards

Clean lines, large size, premium finish — perfect for luxury interiors.

Custom colors, surface treatments, and dimensions available.

📩 DM us for catalogs or project solutions.

#flutedpanels #metalskirting