Laser Cut Decorative Panels: Transforming Spaces with Precision

Table of Contents

In architectural design and interior finishes, the use of finely crafted metalwork is no longer just a detail but a statement. From sophisticated partitions to daring exterior façades, metal panels offer functional and aesthetic value. This blog covers the spectrum of laser cut decorative panels, laser cut screens, laser cut steel sheet, and stainless steel laser cutting, which come together in creating exceptional Stainless steel sheet metal assemblies.

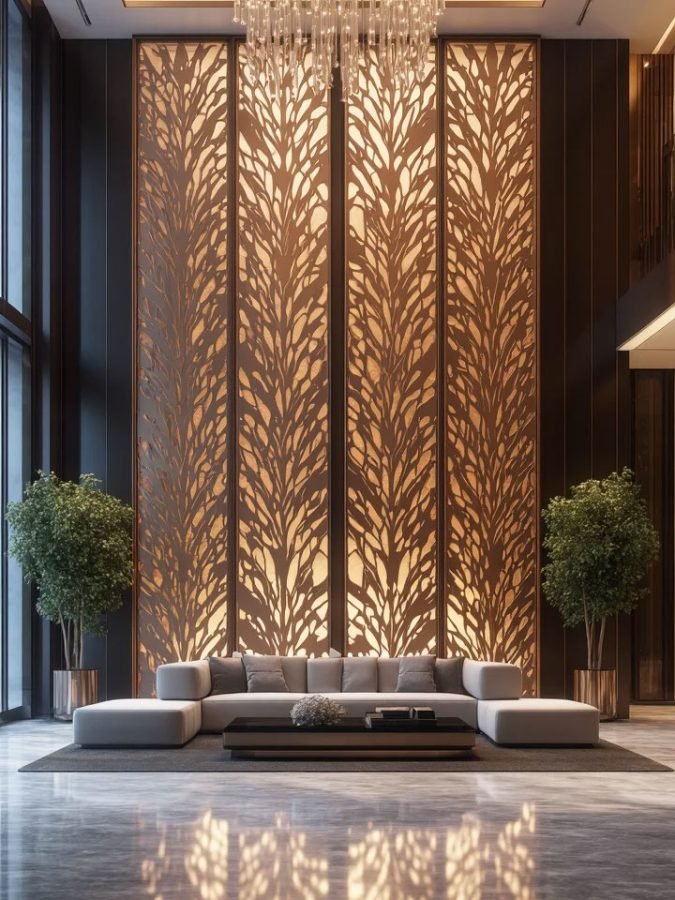

Transforming Interiors and Exteriors with Laser Cut Decorative Panels

Laser-cut decorative panels merge artistry and function to provide metal surfaces that add not only to aesthetic appeal but also to functionality. This is not a plain decoration; it offers practical solutions, like the filtration of light, regulation of airflow, and privacy, while serving as a signature design element. Their versatility allows designers to employ complicated patterns, geometric motifs, or organic shapes, which narrow the gap between industrial precision and artistic creativity.

What Are Laser Cut Decorative Panels?

At their core, decorative panels that are laser cut consist of sheet metal—often stainless steel—that has undergone a laser‑driven fabrication process to create intricate patterns, perforations, or motifs. The precision of laser cutting ensures clean edges and consistent shapes, which allows designers to implement highly detailed designs that would be impossible with traditional metalworking methods. These panels can be used both indoors and outdoors, transforming plain walls, ceilings, or partitions into stunning focal points that enhance the overall environment.

Materials & Finishes to Achieve Aesthetic Impact

Material choice is paramount for performance and looks on the decorative panels. Common usage is 304 or 316 stainless steel, which guarantees perfect corrosion resistance and durability in a very long run. Finishes can include brushed, mirror, sandblasted, or PVD-coated surfaces to achieve everything from subtle matte textures to reflective surfaces which catch the light dynamically. The combination of high-quality materials with accurate laser cutting ensures these panels will be functional and elevate aesthetic quality in any space.

Why Decorative Panels Matter in Commercial Settings

The decorative panel is highly in demand for commercial projects due to its twofold role in aesthetics and functionality. They provide high-class finishes at very competitive prices, support custom branding, and are compatible with OEM/ODM workflows. Be it in a hotel, office, or retail environment, these panels really help architects and designers bring in an element of luxury and sophistication without losing any durability or performance. Their adaptability in size, thickness, and finish makes them an ideal choice for large-scale projects that require bespoke solutions.

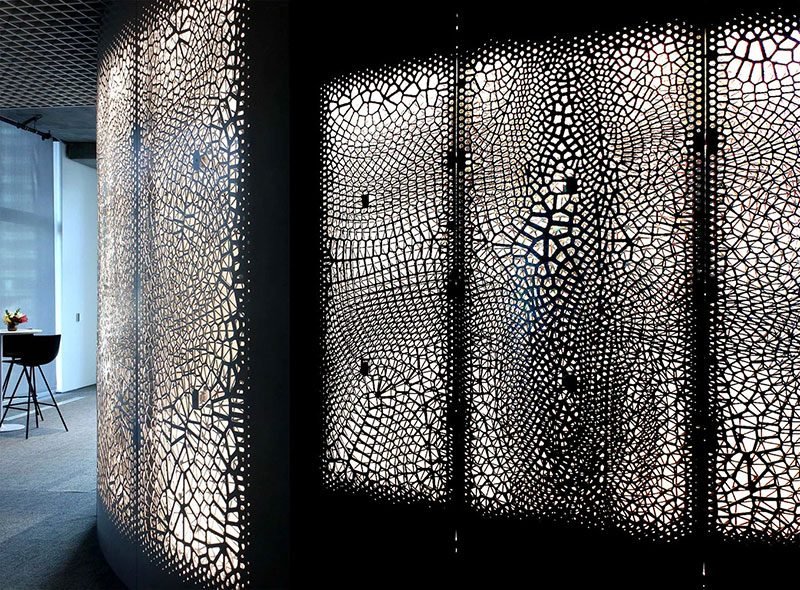

Enhancing Space Functionality and Style with Intricately Designed Laser Cut Screens

Laser cut screens are much more than dividers; they are multi-functional components that merge aesthetics, utility, and architectural ingenuity. With custom patterns applied to these screens and their precise cuts, spaces can be divided without barring light, airflow, or vision while introducing a dramatic flourish to the interior or exterior spaces. This section demonstrates the practical and aesthetic benefits of laser cut screens and how they can enhance modern architectural design.

Defining Laser Cut Screens

A laser cut screen is a panel of sheet metal, normally made from stainless steel or aluminum, which has been treated with laser technology to create very accurate, detailed openings or patterns. These panels can serve as room dividers, garden partitions, balcony guards, or façade elements. Their immediate appeal is that they are able to perform functional separation while maintaining visual continuity and style. Every screen is fully customizable to the client’s design vision, from simple geometric patterns to an elaborate motif.

Manufacturing and Customization Advantage

Laser cut screens allow for significant advantages in manufacturing due to the precision of laser cutting, which ensures consistency and minimal material waste. These screens provide flexible customization options under OEM/ODM or OBM business models in terms of sizes, thicknesses, and pattern complexity. Small and large batch production is equally possible, thus enabling firms to respond promptly to their clients’ needs with consistent quality.

Application in Commercial Projects

In commercial architecture, laser cut screens perform multiple duties: they add visual interest, provide privacy without blocking natural light, and can be incorporated into branding strategies. Their highly modern aesthetic makes them appropriate for hospitality, retail, office, and residential projects alike. With the power of decorative appeal and functional design combined, these screens have the ability to turn spaces into visually dynamic environments that captivate visitors and clients alike.

Achieving Precision and Efficiency with High-Quality Laser Cut Steel Sheets

The basis for every decorative and functional metal product made with lasers consists of a sheet of steel. Quality, thickness, and grade determine the precision of cuts, the durability of the finished product, and complex designs. Understanding the properties of the steel sheets is key to attaining optimal performance in both decorative panels and structural applications.

What is Laser Cut Steel Sheet?

The laser-cut steel sheet refers to the metal blanks, normally of mild steel, carbon steel, or stainless steel, cut accurately by the use of lasers. Cutting with a laser allows for the highest accuracy in contour and pattern, while edge precision remains clean and the heat-affected zones are minimal. This accuracy is important in applications that require consistent quality and exact alignment, such as panels for interior design, facades, and furniture elements.

Technical Considerations and Material Choices

While choosing steel sheets for laser cutting, thickness, material grade, and stress tolerance become critical. For instance, stainless steel has a superior corrosion resistance and strength, although higher laser power may be needed to cut it, with correspondingly slower speeds compared to aluminum or carbon steel. Being in the know regarding these technical considerations makes it possible for manufacturers to produce items in compliance with design specifications and requirements.

Benefits for Manufacturers and Supply Chains

Laser cutting of steel sheets reduces material waste and improves production efficiency, especially for large-scale or repetitive designs. The sheets can go through downstream finishing processes such as powder coating, anodizing, and PVD treatments. For businesses operating under OEM/ODM or OBM models, this versatility means high-quality output at competitive prices with the option of rapid customization to meet client demands.

Elevating Durability and Design with Stainless Steel Laser Cutting Technology

Stainless steel laser cutting is a high-precision manufacturing process that not only strengthens the structure but also enhances the aesthetic value of the metal products. Through the usage of laser technology on sheets of stainless steel, manufacturers are able to provide panels and parts that are structurally strong, visually precise, and long-lasting to meet the high demands of internal and external applications.

What Does Stainless Steel Laser Cutting Offer?

This technology allows for the precise cutting of stainless steel sheets into intricate patterns and shapes, creating finished products featuring clean edges and minimal distortion. The accuracy of laser cutting is critical to decorative panels, screens, and façade elements, especially when complex designs or tight tolerances are required.

Why Use Stainless Steel for Decorative and Structural Work?

Stainless steel is known for its corrosion resistance, structural strength, and ability to accommodate various finishes like mirror, brushed, or PVD coatings. Its durability makes it suitable for environments exposed to weather, humidity, or frequent handling, ensuring that decorative and structural elements maintain their look and function over time.

Implications for Custom Manufacturing and Competitive Pricing

For businesses, the laser cutting of stainless steel allows for high-class, personalized designs at competitive prices. OEM/ODM companies are thus able to scale up the production process efficiently, offering bespoke patterns and sizes to clients at no sacrifice to quality. With this level of precision and durability, added to the design flexibility, stainless steel laser cutting provides a strategic edge in architectural and decorative applications.

Comprehensive Solutions with High-Quality Stainless Steel Sheet Metal

Blending the advantages of laser cutting, stainless steel material, and customized design, the stainless steel sheet metal offers comprehensive solutions for decorative and structural purposes. The material serves as a base for panels, screens, façades, and partitions to ensure aesthetic impact with functional performance.

Understanding Stainless Steel Sheet Metal in Application

From flat to formed, stainless steel sheet metal serves many purposes, from cookware to industrial equipment. Its strength and aesthetic make it perfect for high-traffic areas, outdoor installations, and high-end commercial projects alike. Laser cutting allows even intricate designs to maintain precision, clean edges, and consistency in large-format projects.

Features and Manufacturing Highlights

Some of the key features comprise high precision cutting, customized patterns, large-format project compatibility, and many finishing options. These capabilities enable manufacturers to supply products per client-specific design and performance requirements, yet maintain consistent quality and efficiency.

Business and Market Implications

For companies operating in OEM, ODM, or OBM models, offering stainless steel sheet metal with laser-cut customization provides a competitive advantage. It allows businesses to supply premium, bespoke solutions at competitive prices, catering to clients who demand both functional performance and design excellence. The flexibility and durability of stainless steel sheet metal ensure its relevance in a wide range of architectural and interior design projects.

Conclusion

The combination of laser cut decorative panels, laser cut screens, laser cut steel sheets, stainless steel laser cutting, and stainless steel sheet metal offers a powerful toolkit for architects, designers, and manufacturers. These technologies enable the creation of visually compelling, durable, and highly customizable metal products that enhance spaces, elevate design standards, and provide functional value. By adopting laser-cut stainless steel sheet metal solutions, businesses can deliver high-quality, design-focused metalwork that meets modern aesthetic expectations while offering long-term reliability. Choosing these products ensures clients achieve both striking visual impact and practical versatility, creating environments that are both elegant and enduring.

You Might Also Like

Please Share This

Recent Posts

- Installation Considerations for Metal Decoration

- Decorative Stainless Steel Solutions for Hospitality Projects

- Stainless Steel Decorative Trim Installation Guide: Ensuring Precision, Durability, and Aesthetic Quality

- Quality Control Key Points in Large-Scale Metal Engineering Projects

- Installation Challenges and Solutions for Stainless Steel Hotel Decorations