Stainless Steel Column Cladding: The Ideal Choice for Hotels, Commercial Spaces and Villa

Table of Contents

In today’s architecture and interior design landscape, stainless steel column cladding has emerged as a preferred material for many designers and property owners due to its unique aesthetic value and exceptional practicality. It not only enhances the visual impact of spaces but also provides additional protection for building structures.

This article will delve into the definition, application scenarios, styles, construction, and design aspects of stainless steel column cladding, helping you gain a comprehensive understanding of this architectural finishing material.

What is Stainless Steel Column Cladding?

Stainless steel column cladding cover is a material used in architecture and interior decoration. It involves wrapping stainless steel sheets around the surface of columns to create an aesthetically pleasing and durable decorative effect. This material offers numerous advantages, including corrosion resistance, high-temperature tolerance, easy cleaning, and high strength, enabling it to maintain excellent performance in various environments.

Stainless steel column wrap not only enhances the visual appeal of a space but also provides additional protection for building structures, making it a decorative material that combines both aesthetics and practicality.

Applications for Stainless Steel Column Cladding

Hotel

In hotel lobbies, stainless steel column cladding is frequently used to create a sophisticated and grand atmosphere. Its smooth surface and refined luster elevate the hotel’s overall image, capturing guests’ attention. Whether in modern minimalist or luxurious elegant hotels, stainless steel mirror finish column cover seamlessly integrates, becoming a decorative highlight.

A star-rated hotel incorporated stainless steel cylindrical cladding at its lobby entrance. The designer selected mirror-finished stainless steel as the surface material, employing laser technology to engrave intricate patterns onto the column surfaces. This design not only amplifies the lobby’s opulence but also cultivates an atmosphere of sophistication and grandeur for guests. Following installation, the lustrous finish and premium texture of the stainless steel cladding received high praise from patrons.

Commercial Square

Commercial plazas are high-traffic areas where stainless steel decorative column not only enhances the aesthetic appeal of commercial spaces but also serves as a form of way-finding and spatial division. Its robust and durable properties enable it to withstand various environmental challenges while maintaining long-term visual appeal and functionality.

In commercial plazas, square stainless steel clad columns adorn atrium spaces. Designers selected brushed stainless steel as the surface finish. Considering high foot traffic that may cause surface scratches, this design not only minimizes the visibility of such marks but also contributes to the overall aesthetic. The robust durability of stainless steel clad columns allows them to withstand heavy pedestrian flow and complex environmental conditions, maintaining both visual appeal and functionality over time.

Villa

For villa owners pursuing a high-quality lifestyle, stainless steel pvd coated column casing is an ideal choice. It can be used for both indoor and outdoor decoration, such as columns at villa entrances or landscape pillars in courtyards. The premium texture of stainless steel cladding complements the villa’s luxurious ambiance, showcasing the homeowner’s taste and status.

A luxury villa incorporated stainless steel column enclosure at its entrance. The designer selected either titanium gold sandblasted stainless steel or black matte finishes. This design seamlessly integrates with the villa’s overall aesthetic while showcasing the homeowner’s refined taste and aspirations. The premium texture and durability of stainless steel cladding make it an ideal choice for villa decoration.

Styles and Structures of Stainless Steel Column Covers

Styles

Stainless steel column covers primarily come in two common styles: cylindrical and square. Each style possesses unique characteristics and suitable applications.

- Cylindrical

Cylindrical stainless steel column wraps feature smooth lines, conveying a sense of softness and elegance. They are ideal for spaces requiring a warm ambiance. Their rounded shape reduces visual sharpness, making the space feel softer and more comfortable. Cylindrical stainless steel column wraps are frequently used in hotel lobbies, villa entrances, and similar settings to enhance aesthetic appeal and convey a sense of high-end sophistication.

- Square

Square stainless steel column covers project a sense of stability and grandeur, making them ideal for commercial spaces and large-scale buildings. Their angular shape conveys reliability and authority, fitting perfectly in settings requiring a formal and dignified presence. Square column covers are frequently used in commercial plazas and office buildings to enhance the space’s sense of formality and professionalism.

Structure

The structural design of stainless steel custom architectural column cladding is ingeniously crafted, typically customized based on the column’s dimensions and shape. Key structural design points include:

- Modular Manufacturing

For ease of transportation and installation, cladding panels are often manufactured in modular sections. Each panel’s size and shape undergo precise calculations to ensure seamless on-site assembly that perfectly aligns with the column surface. This modular approach not only simplifies logistics but also guarantees the cladding’s flatness and aesthetic integrity.

- On-Site Assembly

During assembly, technicians employ specialized tools and equipment to ensure uniform, tight joints between panels. Precise joining techniques achieve seamless connections, creating a cohesive, monolithic appearance. After assembly, technicians sand and polish the column surface to achieve the desired gloss and texture.

- Fixing Method

Stainless steel column cover panel is typically secured using a combination of welding and bolting. Welding ensures structural integrity, while bolting facilitates future maintenance and replacement. Technicians employ high-strength welding materials and bolts during installation to guarantee stability and safety.

Design of Stainless Steel Column Cladding

Standard Finishes

Standard finishes for stainless steel column cladding include mirror polish, brushed, and sandblasted surfaces, each offering distinct visual effects and suitability for different applications.

- Mirror Polish

Mirror-polished stainless steel boasts exceptional gloss, reflecting the surrounding environment to make spaces appear brighter and more spacious. Its smooth surface reflects light, enhancing the visual impact of the area. This finish is ideal for creating high-end, sophisticated atmospheres in settings like hotel lobbies and commercial plazas.

- Brushed Finish

Brushed stainless steel features distinctive textured lines, conveying a contemporary, modern aesthetic. Its brushed surface adds visual depth and artistic appeal, making it suitable for spaces requiring a modern or technological feel. The direction of the brushed texture can be customized to enhance decorative impact.

- Sandblasted Matte Finish

Sandblasted stainless steel offers a more subdued aesthetic, ideal for spaces requiring a softer ambiance. Its matte-finished surface reduces light reflection, creating a gentler, more comfortable atmosphere. This finish is well-suited for villas, private clubs, and other settings where a warm, inviting atmosphere is desired.

Perforated or Laser-Cut Designs

Perforated designs represent an innovative approach to stainless steel column cladding. By punching holes in stainless steel panels, diverse patterns and textures can be created, enhancing visual depth and artistic appeal. This design not only offers aesthetic value but also facilitates ventilation and light transmission, making spaces feel more open and comfortable.

- Pattern Design

Perforated patterns can take diverse forms—geometric shapes, natural landscapes, abstract art—customized to meet specific design requirements. Geometric perforations lend a modern, technological feel to spaces, while natural-inspired patterns evoke a sense of nature and artistry. Abstract designs, meanwhile, infuse spaces with personality and creativity.

- Ventilation and Light Transmission

Another key function of perforated designs is ventilation and light transmission. In spaces requiring airflow and natural illumination—such as atriums in commercial plazas or hotel corridors—perforated patterns effectively improve ventilation and daylighting conditions, enhancing overall comfort.

- Precision Processing

Laser design also excels in precision processing. Laser technology achieves micron-level accuracy, enabling flawless reproduction of intricate patterns and textures. This precision not only elevates decorative effects but also enhances the artistic value and visual appeal of stainless steel column cladding.

Stainless Steel Water Ripple Design

Stainless steel water ripple design is a distinctive decorative technique that employs specialized processes to create wave-like textures on stainless steel surfaces, producing a fluid visual effect. This design not only possesses exceptional artistic value but also adds a dynamic aesthetic to interior spaces.

- Texture Characteristics

The texture of stainless steel water ripple patterns features natural, fluid characteristics, resembling gentle ripples on a water surface. This texture evokes a sense of tranquility and softness, making it ideal for spaces requiring a relaxing atmosphere, such as hotel lounges or leisure areas in private clubs.

- Application Scenarios

Stainless steel water ripple column wraps find extensive use in hotel lobbies, atriums of commercial plazas, and villa courtyards. In hotel lobbies, wave-patterned column cladding can integrate with water features to create a seamless visual effect of sky and water, elevating the space’s sophistication and artistic appeal. In commercial plaza atriums, it harmonizes with surrounding landscape designs to enhance natural ambiance and comfort. In villa courtyards, it blends with natural scenery to cultivate a tranquil, elegant atmosphere.

- Design Advantages

Stainless steel water ripple cladding cover offer both aesthetic appeal and practical functionality. Their textured surfaces enhance light refraction, making spaces appear brighter and more transparent. Additionally, the ripple pattern reduces direct light reflection, creating softer, more comfortable illumination. This design not only elevates visual appeal but also delivers a superior user experience.

Installation and Maintenance of Stainless Steel Column Cladding

Installation

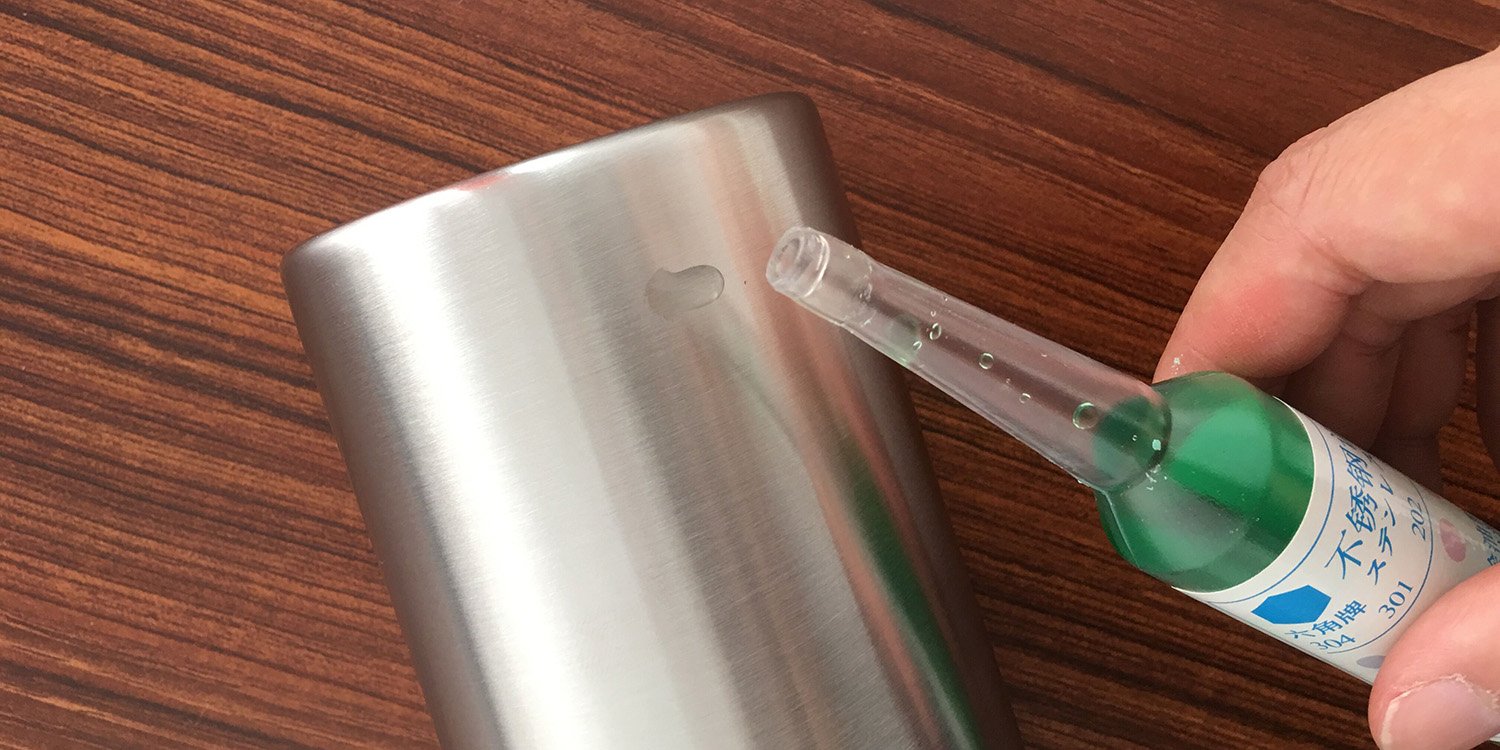

The installation of stainless steel decorative column cover requires professional technicians and equipment. During installation, first ensure the column surface is flat and clean, then assemble and secure the cladding panels according to design specifications. Pay attention to gap treatment between panels to guarantee the cladding’s aesthetic appeal and structural integrity.

Maintenance

Maintenance of stainless steel column cladding is relatively straightforward. Due to its corrosion resistance and easy-to-clean properties, periodic wiping with water or mild detergent suffices. For stubborn stains, specialized stainless steel cleaners may be used. Regular upkeep preserves the cladding’s luster and performance while extending its service life.

Conclusion

As a modern architectural and interior decoration material, stainless steel column cladding has gained widespread popularity for its aesthetic appeal, durability, and ease of cleaning. Whether in hotels, commercial plazas, or villas, stainless steel column cladding showcases its unique charm. Through diverse styles, structures, and design approaches, it meets the needs of different clients, enhancing the beauty and value of various spaces.

By choosing JYF METAL brand stainless steel column cladding, you gain access to premium products and professional services, delivering exceptional decorative results for your project.

You Might Also Like

Please Share This

Recent Posts

- Installation Considerations for Metal Decoration

- Decorative Stainless Steel Solutions for Hospitality Projects

- Stainless Steel Decorative Trim Installation Guide: Ensuring Precision, Durability, and Aesthetic Quality

- Quality Control Key Points in Large-Scale Metal Engineering Projects

- Installation Challenges and Solutions for Stainless Steel Hotel Decorations