Why Stainless Steel Etched Sheets Are the Best Choice for Strength and Style

Table of Contents

Imagine a new metal sheet proves strong, durable, and optimized for aesthetic designs. A material capable of sustaining the hostilities of the weather, extremely hot temperatures, and daily usage and still retaining a good appearance. This is exactly what stainless steel etched sheets provide to those who opt for it.

They are used in automotive and interior design, especially in fancy restaurants, and likewise in beautiful inscriptions and engravings on the exterior of buildings. However, that is why they are preferred over other metals. The answer is short and clear: they are beautiful, strong, and can be easily adapted to any of the above characteristics. Let’s dive into the topic!

What Is a Stainless Steel Etched Sheet ?

Etched stainless steel sheet is a thin sheet of steel with specific patterns, textures, and designs on the surface. These are designs produced on brass through a process known as etching which involves cutting a thin strip of metal on the surface of the utensil.

Manufacturing Process of Stainless Steel Etched Sheets

In the context of producing etched stainless steel sheets, there are two possible methods:

- Chemical etching - Certain chemicals are used to dissolve some of the unwanted parts of the metal and make these delicate designs.

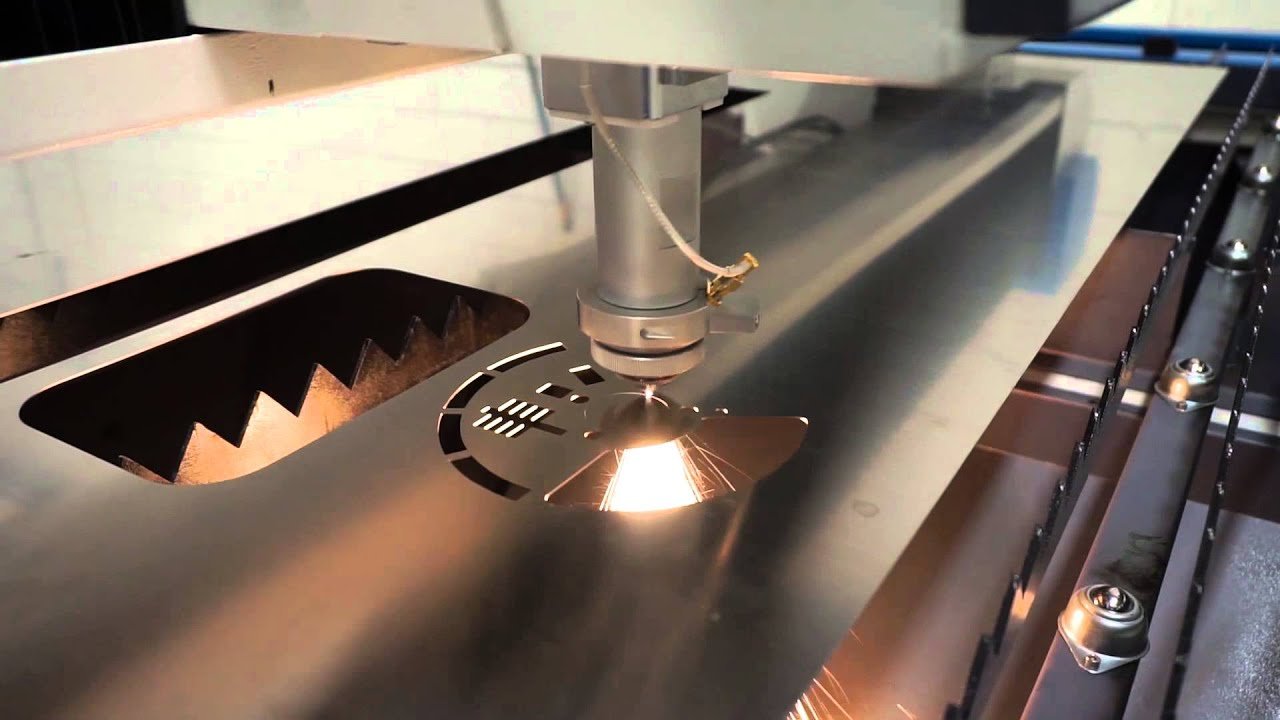

- Laser Etching – The laser hermetically welds a design onto the surface and vaporizes it.

Depending on the desire of the company, the sheets that have been etched can have various finishes as follows:

- Metal Foil Polish – Some of the brightest and shiniest among them, which could be appropriately incorporated into any contemporary interior.

- Brushed finish – A surface finish with a low sheen that does not show fingerprints and finger marks and has low visibility of scratches.

- Matte Finish – A non-reflective surface, great for an understated, professional look.

As they are elegant, strong, and durable, they have applications in construction, design, circuit boards, cars, and sensors, as well as medical tools.

The Best Things about Stainless Steel Etched Sheets

So, there is question: Why choose the stainless steel etched sheet over other types of metal? All these answers can be credited to the excellent qualities of the product.

Rust-Resistant and Long-Lasting

This means that rusting cannot easily happen since the compound that is used to make it does not corrode easily. As for the practical application, it is worth mentioning that stainless steel does not corrode and wears out much quicker than normal steel, which has to be periodically replaced. It makes it ideal for outdoor applications and any other area with high humidity and even some portions of the marine climate.

However, some types of stainless steel sheets undergo passivation, a procedure that makes them more anti-corrosive compared to other materials.

Super Strong and Durable

Nonetheless, the etching done to the sheet erases a layer of the metal, and yet the sheet does not become in any way flimsy. It neither wears, splits, nor breaks and is perfect for areas with many people, such as elevators and public buildings or areas where it is used in the manufacture of industrial tools.

Handles High Temperatures

Some items, such as plastic or painted metals, can be deformed by heat. For instance, they melt quickly. It has enormous uses, as it can undergo high temperatures and still not affect its strength. This is why it is widely applied in the kitchen, different types of processing houses, and even in planes.

Safe for Food and Medicine

Stainless steel has many advantages, including the following: Firstly, it does not pose any health hazards as it is non-toxic. Secondly, it is easy to clean and does not interact with chemicals. As a result, it is suitable for:

- Medical equipment– It inhibits bacterial growth and thus makes them ideal for use in hospitals as well as laboratories.

- Bleaching – It has been used in the food processing industry, especially when it comes to kitchen places, cooking utensils as well as kitchen appliances.

Safe for Food and Medicine

The etching process deforms a portion of the top-most layer while thinning it slightly so that the whole sheet becomes lighter at the same time being stronger. : However, it is especially useful for industries such as automobile and aerospace since lightweight enables engineers and manufacturers to use less fuel.

Why Etching Is Better Than Other Metal Treatments

Perfect Designs Every Time

Etching is very intricate hence a manufacturer can draw fine and complex designs. This is advisable for sectors such as electronics and circuit boards where minuscule fora and errors are not acceptable.

Easy to Customize

It also has the advantage of not necessitating the use of forms that are costly compared with other metal forming techniques, yet it makes it possible to etch the chosen design to the metal. This also makes it convenient to design unique ID designs, logo designs, signages, and any other architectural panels.

Environmentally Friendly

Stainless steel is fully reusable, and the process of etching is relatively environmentally friendly compared to other processes, such as painting and engraving. It is essential for you or any designer to understand that the use of etched stainless steel is very sustainable.

Functional Benefits: More Than Just Looks

Stainless etch products are indeed the best when it comes to designs and stainless steel etched sheets also offer the following benefits.

Textured Surfaces Improve Functionality

Different surface patterns can:

- Optimize gripping – Great for the construction of stairs, floors, and industrial machinery.

- Adhesion improvement – This is suitable in cases where there is a need to paint or laminate.

- Enhance filtration – Used in tapes for vents and barrier for filter parts, sieves, filter materials, and filters.

Perfect for Different Design Styles

Due to the variety in color, finish, and pattern of these sheets, the following uses apply:

- Luxury interior design – Hotels, offices, and high-end apartments.

- Car accessories – dashboard trims and branding logos.

- Storefront and general signs – Open, closed, fair prices, and bulk sales signs, all signage containing the company’s name or logo.

Reduces Weight Without Losing Strength

There are some characteristics of etched sheets that make them more suitable for use in the automotive and aerospace industries; they are light in weight but at the same time strong. It enhances the fuel economy as well as the performance of the automobile vehicle.

Application of Etched Stainless Steel Sheets

Architecture & Interior Design

Etched sheets of stainless steel are used in construction and interior designs to give a classy and vintage design. They are applied for wall cladding, hotel halls, and luxury ceilings, as well as other external and internal coverings. In the elevator, an etched sheet is used as decoration for the door and cabin wall, as well as to create a harder surface for scratch.

Electronics & Medical Tools

In electronics, the sheets are used in producing circuit boards, shielding, electronic components, and other highly precise parts and tools. These due to their conductivity and accuracy are greatly suitable in any electronic device. In health care, stainless steel etched sheets are applied with the tools and sterile trays as well as in health care instruments and equipment because they are easier to clean, hygienic, and non-corrosive.

Why JYF Metal Is the Best Choice for Stainless Steel Etched Sheets

In the automotive industry, these sheets are applied in dashboard trims, branding components as well as unique conception designs for vehicles. Their application in aerospace includes in interior part of the aircraft, the heat shield, and some parts of the engine.

By integrity of its strength, appearance, as well as versatility, stainless steel etched sheets remains one of the most preferred products around today.

Why is JYF Metal the Right Company for Your Room Divider Needs?

If you are seeking stainless steel etched sheets of superior quality, you should consider JYF Metal. Here’s why:

- Quality – Only top-quality and high-grade stainless steel material is used.

- Advanced Etching Technology – Ensures precise and high-quality patterns.

- Custom Designs – Customize them as per your wish and get them in any design, color, and texture that you prefer.

- Fast Delivery & Affordable Prices – Reliable supply for large and small projects.

Conclusion

Stainless etched sheet is not just a type of metal or a material to be used for decoration, but it is also a beneficial material that can be employed in various fields. Both of these types of sheets provide the best performance results that the consumer needs in terms of hardness strength, rust resistance, and even uniqueness in design.

So, if you are the one who wants to add them in your next project, discover stainless steel etched sheets from JYF Metal: we provide the highest quality !

You Might Also Like

Please Share This

Follow Us On Twitter

On-site Installation of Stainless Steel Screen Partition

Precision-made. Professionally installed.

Transforming spaces with durable, elegant metal dividers.

📮DM us for custom design and project support.

#interiordecoration #metalpartition #roomdivider #sheetmetalfab

Café Design | A Sensory Collision of Metal and Coffee

This design is from BOUNDLESS SPACE DESIGN OFFICE

If you are interested in stainless steel decorative materials, please contact me for a quote !

Email: claire@jyfmetal.com

#interiordecoration #decorativematerials #metallic

Stainless Steel Fluted Panels & Skirting Boards

Clean lines, large size, premium finish — perfect for luxury interiors.

Custom colors, surface treatments, and dimensions available.

📩 DM us for catalogs or project solutions.

#flutedpanels #metalskirting