Why Colorful Stainless Steel is a Game-Changer for Interiors?

Table of Contents

In the design world, fantasy elements often create an independent color system that is both advanced and imaginative. The recent trend of using colorful stainless steel in design has made it a top choice in the material world. Wherever it is used, it becomes a dazzling focal point that is impossible to ignore.

What is Iridescence Stainless Steel ?

Definition of Iridescence Stainless Steel

Iridescence stainless steel, also known as phantom stainless steel, colorful stainless acid-resistant steel, is a type of stainless steel. This material, with corrosion resistance as its main characteristic and a chromium content of at least 10.5% and carbon content not exceeding 1.2%, achieves its unique color effects through resin coating, chemical and electrochemical coloring, and PVD vacuum coating technology.

Features of Magic Color Stainless Steel

– Decorative

This material is hard and cold with a metallic luster, making it an avant-garde decorative choice. Its colorful and dreamy effect enhances its decorative appeal.

– Excellent Performance

It boasts excellent corrosion resistance, fire resistance (high temperature resistance), environmental resistance, and good forming, compatibility, and toughness. It has a long service life and is easy to clean.

– Various Processing Technologies

It can be processed through hot pressing, cold bending, cutting, welding, and more, demonstrating excellent process performance.

– Environmentally Friendly

It is a new industrial product that saves resources, does not release formaldehyde or radiation, and is 100% recyclable, reducing the energy consumption of precious metals and promoting environmental protection and safety.

– Wide Application

It is extensively used in heavy industry, light industry, daily necessities, and building decoration.

Common Parameters

The common size specifications of colorful stainless steel sheets are 1000 × 2000mm, 1219 × 2438mm ( or 4 ×8 ft ), 1219 × 3048mm ( or 4 ×10 ft ), 1500 × 3000mm. The thickness range usually spans from 0.5 to 3.0mm. These parameters are widely used in the market.

Price Range

The price of colorful stainless steel varies depending on composition, origin, size, thickness, coloring process, and brand. For example, a 201 series plate sized 1220 × 2440 × 1.0 mm typically sells for 580-1200 yuan per piece. Prices fluctuate based on different items, brands, and custom requirements.

Classification and Material Comparison

Categories of Fancy Stainless Steel

Depending on the coloring process, colorful stainless steel can be divided into resin coating, chemical and electrochemical oxidation film coloring, and PVD vacuum coating.

– Resin Coating Process

This involves coating the substrate with polyvinyl chloride or films such as polyacrylate, epoxy, and alkyd resins, or applying organic, inorganic, or composite coatings.

– Chemical and Electrochemical Oxidation Film Coloring

This process forms a colorless, transparent chromium oxide film on the substrate’s surface through electrolysis and curing. The film’s light interference creates various color effects.

– PVD Vacuum Coating Process

This physical method vaporizes the material into atoms, molecules, or ions under vacuum conditions.

Material Comparison (with Magic Glass)

– Decorative Quality

Colorful stainless steel shows different magic color effects based on substrate polishing, film composition, thickness, environment, and light incidence. It can also present a mirror-like brightness and texture.

– Coloring Process

While colorful stainless steel uses resin coating, chemical and electrochemical oxidation, and PVD vacuum coating processes, magic glass mainly uses film processes for coloring. Laminated glass involves adhesive PVB film between glass pieces.

– Application Scope

Colorful stainless steel allows for arbitrary cutting, splicing, and bending, suitable for both indoor and outdoor building spaces. Magic glass can be toughened, laminated, or hollowed and is prefabricated in factories for indoor and outdoor use.

Construction Technology of Iridescence Stainless Steel

Colorful stainless steel plates are primarily used for wall decoration in indoor spaces. Their construction process is similar to that of aluminum plates:

Construction Process of Dry-Hanging Stainless Steel Wall

– Preparation for Construction

- Review Design Drawings: Carefully examine the design drawings to understand the requirements and specifications. Ensure that the colorful stainless steel plates are straight and square according to the drawings.

- Material Measurement and Cutting: Measure the dimensions on-site to determine the exact size and number of decorative wall panels required. Mark and cut the colorful stainless steel plates to the necessary sizes, ensuring accuracy and precision.

- Mock-Up Wall: Construct a model wall as a reference to verify the design and installation process. Once the model wall is approved, proceed with mass production and processing of the panels.

– Elastic Line Positioning

- Marking Frame Positions: Use a measuring tape and chalk line to accurately mark the positions of the frames on the main structure. Ensure that the lines are straight and precisely positioned according to the design specifications.

- Detailing Fixing Points: Clearly mark the positions for the fixing parts, ensuring consistency and alignment with the frame positions.

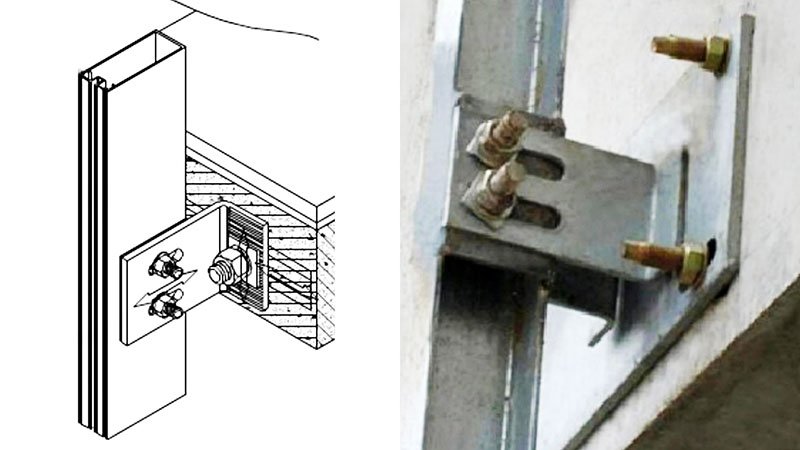

– Fix the Connector

- Expansion Bolts for Non-Embedded Walls: For walls without embedded parts, use expansion bolts to securely fasten the connectors to the main structure. Ensure the bolts are tight and stable to provide a solid foundation for the keels.

- Welding for Embedded Parts: For walls with embedded parts, weld the connectors to the embedded parts. Perform anti-rust treatment on the welds to prevent corrosion and ensure longevity.

– Install the Keel

- Choosing the Keel Material: Select suitable keel materials, such as steel keels or aluminum alloy profiles, based on the project requirements.

- Fixing the Keel: Secure the keels to the connectors using bolts or welding, ensuring they are firmly attached. Regularly check the elevation and centerline positions during installation to maintain alignment and accuracy.

– Install Colorful Stainless Steel Plates

- Drilling Screw Holes: Use an electric drill to create holes in the designated positions on the stainless steel plates for screws. Ensure the holes are evenly spaced and aligned with the keels.

- Securing the Plates: Fix the plates to the keels using self-tapping screws, securing them block by block. Ensure each plate is firmly attached and properly aligned with adjacent plates.

– Seam Treatment

- Leaving Gaps for Seams: Leave a gap of 10-20 mm between adjacent plates to accommodate expansion and contraction.

- Filling Seams: Use sealant or other elastic materials to fill the gaps between the plates. Ensure the sealant is evenly applied and fills the entire gap, creating a smooth, continuous seam.

– Product Protection

- Protective Covering: Apply plastic tape over the installed plates to protect them from scratches and damage. In areas prone to impact, add additional railing protection.

- Removing Protective Film: If the stainless steel plates come with a protective film, remove it after installation to reveal the finished surface.

– Anti-Rust Treatment

- Treating Weld Surfaces: Apply anti-rust paint to all weld surfaces, connection points, and fixed points before proceeding to the next step. Ensure thorough coverage to prevent corrosion.

– Pre-Construction Inspection

- Pre-Installation Checks: Conduct a thorough inspection of the pre-construction elements to ensure compliance with the construction standards. Address any issues before installing the stainless steel plates, as post-installation inspections are difficult.

– Handling During Installation

- Avoiding Surface Damage: Handle the stainless steel plates with care to avoid contact with hard objects that could scratch the surface. Use soft gloves and appropriate lifting equipment to prevent damage.

By following these detailed steps, the installation of colorful stainless steel plates can be executed with precision and care, ensuring a high-quality finish that enhances both the aesthetic and functional aspects of the interior space.

JYF METAL: Your Partner in Innovative Stainless Steel Solutions

At JYF METAL, we pride ourselves on providing top-quality colorful stainless steel products that meet the highest standards of performance and aesthetics. Whether you’re looking to enhance your space with the dazzling effects of phantom stainless steel or seeking durable and environmentally friendly solutions, our extensive range of stainless steel materials and expert construction techniques ensure your projects stand out. Trust JYF METAL to bring your design visions to life with innovation and excellence.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions