Understanding Metal Laser Cutting: A Comprehensive Guide

Table of Contents

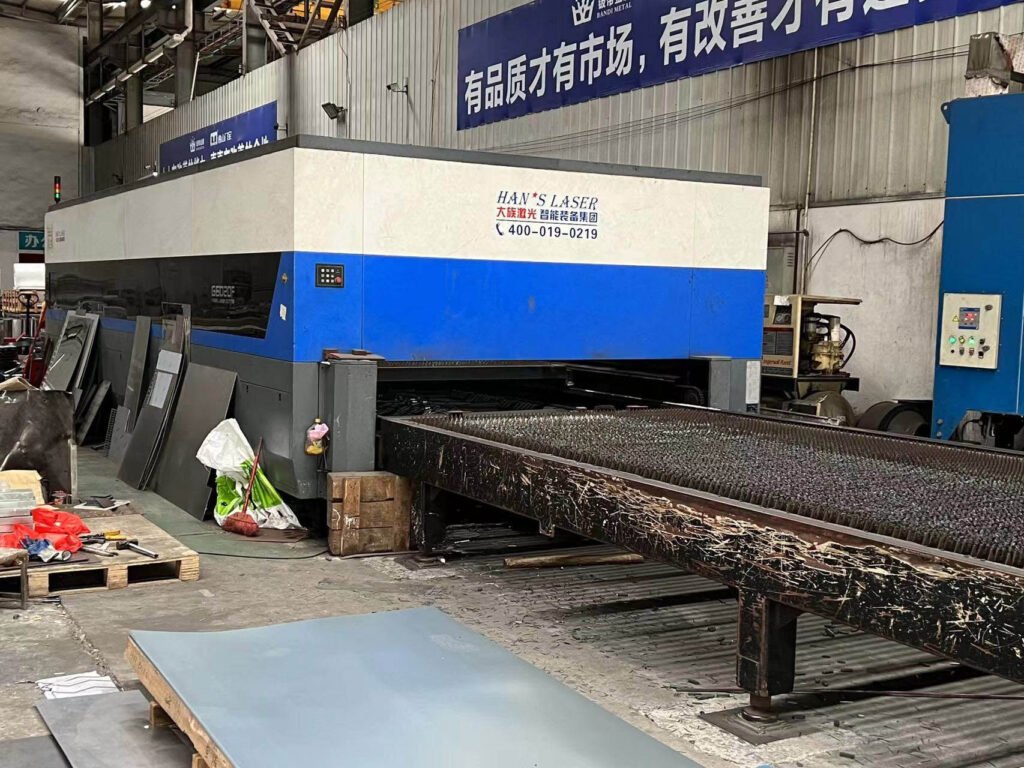

What Is Metal Laser Cutting?

When it comes to metal fabrication techniques, laser cutting is swiftly gaining prominence across various sectors, from aerospace to medical technology. This modern method uses a high-intensity laser beam to effortlessly slice through stainless steel and other metallic materials. Unlike traditional mechanical processes, laser cutting is fast, precise, and reduces wear and tear on machinery, making it a preferred choice for achieving superior product quality.

How Does It Operate?

Owing to its ability to be calibrated, the laser can be fine-tuned to emit varying levels of energy, tailored to the specific material and its thickness. The outcome is generally a cleanly finished product, owing to the exactitude of the laser beam.

The technology’s agility and pinpoint accuracy make it the go-to option for crafting complex shapes and intricate designs. For instance, it can execute ornate patterns, undulating edges, and minute perforations that would be otherwise unattainable with conventional cutting instruments. The beam’s minuscule size—sometimes as narrow as .001 inches—enables exceptional precision, particularly useful for miniature components.

Additionally, the swiftness of the laser-cutting procedure makes it a favored option for industries that require mass production in a time-efficient manner. It often even negates the need for subsequent processes like grinding, sanding, or painting, which could otherwise drive up manufacturing costs and extend production time.

Pros and Cons of Utilizing Laser Cutting

Speed is another merit. The laser beam’s ability to focus on one area before moving slightly to address the next allows for quicker completion of each component compared to older, mechanical methods. For industries planning on high-volume production, this translates to significant cost benefits.

Moreover, the finished components might require additional treatments like deburring or polishing to reach their final form, adding to the overall expense.

Lastly, the process can generate environmental hazards like fumes, smoke, and particulate matter, depending on the material being cut. These pollutants necessitate an extraction system to safeguard workers’ health, which adds another layer of cost to the process.

JYF Metal: Premium Metal Laser Cutting Services

Elevate Your Manufacturing With Our Laser Cutting Solutions

In the constantly evolving world of manufacturing, metal laser cutting is becoming more than just an option—it’s a necessity. At JYF Metal, we’re at the forefront of this technological shift, delivering unparalleled laser cutting services tailored to your needs.

Why Choose JYF Metal's Laser Cutting?

- Wide Range of Materials: We cater to diverse needs, offering laser cutting for stainless steel, aluminum, copper, and brass. Our versatility ensures your specific material requirements are met with utmost precision.

- Precision is Our Middle Name: Our advanced technology can produce both simple and intricate designs with exactness. We pride ourselves on achieving tolerances of up to +/-.002”, ensuring your components are crafted to perfection.

- Accommodating Various Batch Sizes: Whether you need a small prototype batch or a large production run, JYF Metal has the capabilities to handle projects of any scale. Our equipment can manage sheet sizes up to 48” x 120”.

- State-of-the-Art Features: Our laser cutters are equipped with an automated parts loader system, maximizing efficiency and ensuring quick turnaround times.

- Comprehensive Capabilities: From 3D cutting, slots, and notches to specialized tight tolerance programs, our services are tailored to meet the most stringent project requirements.

- Cost-Effective and Quick: Laser cutting is not only precise but also eliminates additional tooling costs and shortens lead times. This ensures a swift, cost-effective solution for your needs.

Our Commitment to Excellence

Recognizing the value of time in the manufacturing sector, we offer unparalleled support throughout the production process. From insightful consultations to timely deliveries, we ensure a seamless experience devoid of unforeseen costs.

Your Success is Our Priority

Our commitment doesn’t stop at delivering high-quality components; it extends to guaranteeing prompt deliveries, competitive pricing, and unwavering precision. If you seek a trusted partner in laser cutting, JYF Metal is here to transform your vision into a tangible reality.

Reach Out Today !

If top-notch laser cutting services are on your agenda, don’t hesitate. Contact JYF Metal, and let us craft the optimal laser cutting strategy for your endeavors.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions