The ABCs of Stainless Steel Cladding Maintenance

Table of Contents

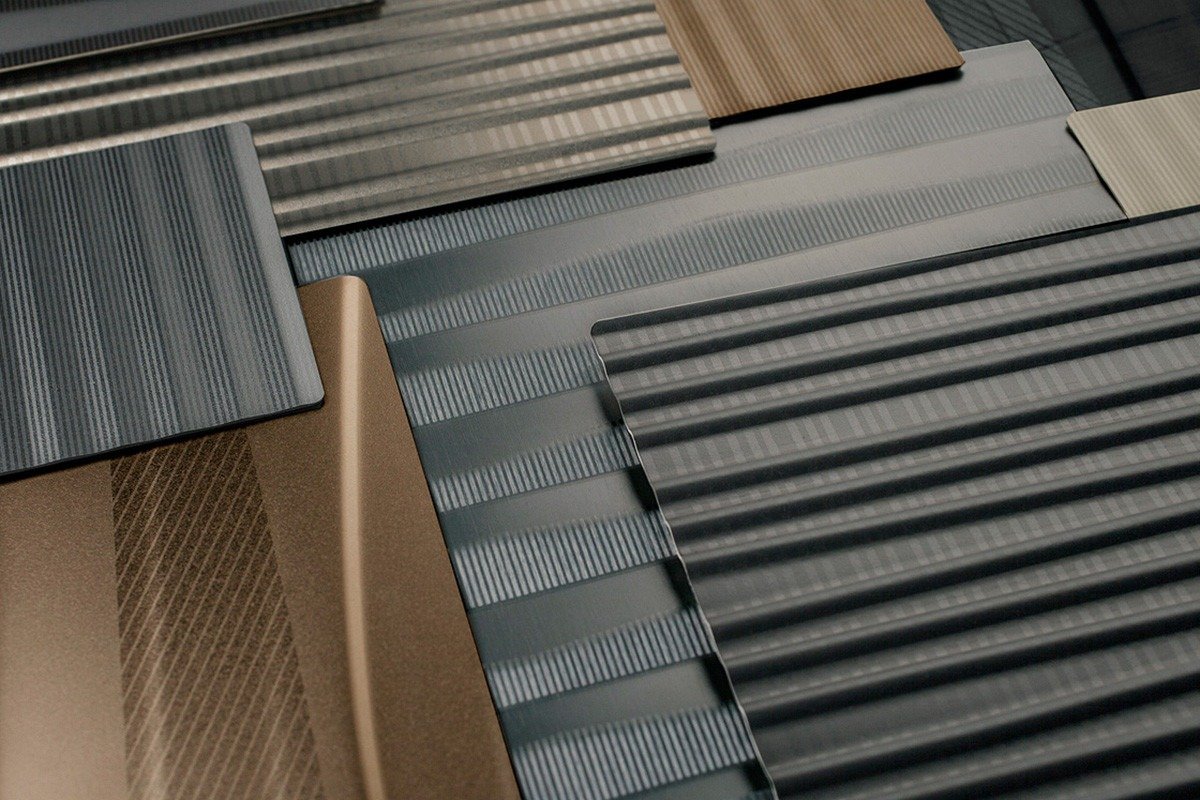

Decorative stainless steel cladding is widely used in various applications, adding a touch of elegance and sophistication to spaces. To preserve their aesthetic appeal and extend their lifespan, it is essential to understand the potential risks of damage and implement proper maintenance practices. This article presents a comprehensive guide on maintaining decorative stainless steel panels, covering the production process, installation process, and post-installation care.

Risks of Damage to the Surface of Stainless Steel Cladding

Scratches and Abrasions

Stainless steel panels are susceptible to scratches caused by sharp objects, abrasive materials, or improper handling during production, transportation, installation, or maintenance. These scratches can mar the surface and compromise the visual appeal.

Stains and Corrosion

Exposure to corrosive substances, such as saltwater, harsh cleaners, acidic solutions, or prolonged moisture, can lead to staining or corrosion on the surface of the stainless steel cladding panels. These blemishes can dull the finish and weaken the material.

Fingerprint Marks and Smudges

The smooth surface of decorative stainless steel cladding may easily display fingerprints and smudges, especially in high-touch areas. Over time, these marks can accumulate and diminish the overall appearance.

Maintenance During the Production Process

During the production process of colored stainless steel cladding, several important steps should be taken to ensure the highest quality and minimize the risk of surface damage. These steps include material selection, size and thickness checks, and the application of specific processes tailored to the desired finish of the panels.

Material Selection and Inspection

Careful selection of high-quality stainless steel materials is crucial for producing durable and visually appealing panels. This includes considering factors such as grade, composition, and surface finish. Thorough inspections should be conducted to identify any defects or irregularities that could affect the final product.

Mirror Stainless Steel Sheets

For mirror-finished stainless steel sheets, a precision grinding process is employed to achieve a flawless, highly reflective surface. This process ensures that no visible scratches or imperfections are present, maximizing the aesthetic appeal of the panels.

Brushed Stainless Steel Sheets & PVD Stainless Steel Sheets

To enhance the durability and visual appeal of brushed stainless steel sheets and those with a PVD (Physical Vapor Deposition) coating, an anti-fingerprint technology is often applied. This technology helps to reduce the appearance of fingerprints, stains, and smudges, ensuring that the panels maintain their pristine appearance over time. Additionally, it provides protection against rusting and fading, contributing to the longevity of the panels.

By adhering to these meticulous production practices, manufacturers can produce colored stainless steel cladding panels of exceptional quality, with surfaces that are free from scratches, corrosion-resistant, and visually striking. This ensures that the panels are well-prepared for installation and require minimal maintenance to preserve their appearance and performance in the long run.

Maintenance During the Installation Process

Protective Measures

Cover the surface of the stainless steel cladding with a temporary protective film during transportation and installation to safeguard them against scratches and stains from construction debris or tools.

Proper Handling

Construction personnel need to wear gloves for installation work, which not only protects materials and avoids leaving fingerprints or stains, but also better protects the safety of construction personnel and avoids scratches or injuries.

Avoid Contamination

Ensure the installation area is clean and free from corrosive substances or other pollutants. Promptly clean off any accidental spills or debris during the installation to prevent stains or corrosion.

Tear off the Protective Film

If the wall decoration is made of stainless steel sheets paired with paint or cement, the protective film on the stainless steel plate needs to be removed after all processes are completed, which means that removing the protective film is the final step of the installation work. Because after tearing off the protective film, paint spraying or cement application can splash onto the stainless steel panel, which can have irreversible consequences on the stainless steel surface.

Maintenance After Installation

Regular Cleaning

Clean the stainless steel cover panels regularly using a mild, non-abrasive stainless steel cleaner or a mixture of mild dish soap and warm water. Gently wipe the surface with a soft cloth in the direction of the grain, rinsing thoroughly and wiping dry to eliminate water spots.

Stain Removal

For stubborn stains or fingerprints, use specialized stainless steel cleaners or gentle rubbing alcohol. Apply the cleaner to a soft cloth and gently rub the affected areas, following the grain pattern. Rinse and dry as mentioned above.

Protective Coatings

Consider applying protective coatings designed for stainless steel to enhance resistance against fingerprints, smudges, stains, and corrosion. Consult with professionals for suitable coating options based on the specific ambiance and usage of the stainless steel panels.

In Conclusion

To maintain the pristine appearance and longevity of decorative stainless steel cladding panels, proper maintenance practices should be followed throughout the production process, installation, and after installation. By being vigilant about potential risks, implementing protective measures, and adopting regular cleaning routines, one can ensure that these beautiful decorative panels continue to enhance the aesthetic appeal of various spaces for years to come. Remember, regular care and attention will help preserve the beauty and durability of your stainless steel cladding.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions