Stainless Steel Outdoor Sculpture: A Landmark and Brand Symbol for Hotels

Table of Contents

In the architectural aesthetics of modern hotels, outdoor sculptures have become an indispensable element. They not only enhance the artistic ambiance of the hotel but also serve as a distinctive emblem, showcasing the hotel’s cultural heritage and sophisticated taste.

Large stainless steel outdoor sculptures, with their unique material and exquisite craftsmanship, are increasingly becoming the preferred choice for hotel signage. This article will delve into the allure of stainless steel large modern sculptures and their significance in hotel branding.

Definition and Characteristics of Stainless Steel Sculptures

Definition

Stainless steel sculptures are artistic works crafted from stainless steel materials through artistic processing. They combine the durability of modern materials with the artistic qualities of traditional sculpture, presenting a unique visual impact. Typically used in outdoor settings, stainless steel artworks maintain their appearance over time without frequent maintenance due to their corrosion resistance, high-temperature tolerance, and wear resistance.

Characteristics

- Corrosion Resistance

Stainless steel contains elements like chromium and nickel, which form a dense oxide layer that effectively prevents oxidation and corrosion. Even in harsh natural environments such as coastal areas or industrial zones, it can maintain its integrity for decades.

- High-Temperature Resistance

Stainless steel remains stable under elevated temperatures, resisting deformation or damage from thermal fluctuations. This enables outdoor sculptures to withstand extreme weather conditions.

- Abrasion Resistance

Stainless steel possesses high surface hardness and excellent wear resistance. Even in high-traffic areas like hotel entrances or plazas, the sculpture’s surface remains resistant to scratches and wear.

- High Malleability

Stainless steel is easily workable and can be shaped into complex forms and designs through various processes like forging and casting. This provides sculptors with extensive creative freedom, enabling the realization of diverse artistic styles ranging from abstract to realistic.

Stainless Steel Sculpture Techniques: Forging and Casting

Forging Process

Forging is a mechanical process that shapes metal materials into desired forms. In stainless steel sculpture, the forging process primarily involves the following steps:

- Design and Modeling

Sculptors first create a model based on design specifications, typically using foam, plaster, or other malleable materials. The base model is then sectioned to facilitate hammering and shaping in subsequent steps.

- Cutting and Forming

Stainless steel sheets or profiles are cut to appropriate dimensions and shapes. Through mechanical processing such as hammering and bending, these pieces are formed into individual sculpture components. Sculptors attach the hammered parts to the base model, ensuring their curves align seamlessly with the sculpture’s contours.

- Welding and Assembly

Formed sections are joined through welding to create the complete sculpture structure. Welding parameters are strictly controlled during this process to ensure weld quality.

- Grinding and Polishing

After welding, the sculpture’s surface undergoes grinding and polishing. This not only removes weld marks but also creates a smooth, refined finish that highlights stainless steel’s characteristic luster, achieving a mirror-like effect.

- Surface Treatment

Finally, the sculpture’s surface is treated according to design specifications—such as spray painting or PVD coating—to enhance its aesthetic appeal and durability.

Casting Process

Casting is a technique that involves melting metal materials and pouring them into a mold, where they cool and solidify into the desired shape. In stainless steel sculpture, casting is typically used to create complex forms, following these steps:

- Design and Modeling

Similar to the forging process, the sculptor first creates a model of the sculpture.

- Mold Making

The model is replicated into a mold, typically using materials like silicone or epoxy resin. The precision of the mold directly impacts the quality of the cast sculpture.

- Melting and Pouring

Stainless steel material is melted and then poured into the mold through a pouring system. Temperature and speed must be carefully controlled during pouring to ensure the metal fills the mold evenly.

- Cooling and Demolding

After pouring, the metal is allowed to cool naturally within the mold. Once fully solidified, the mold is opened to remove the cast sculpture.

- Post-Processing

The cast sculpture undergoes cleaning, grinding, welding, and other finishing processes to repair any defects and meet design specifications.

Compared to the two, forging is more commonly used and less expensive. JYF METAL will analyze your stainless steel sculpture design requirements and provide recommendations. Some designs may incorporate a combination of both techniques.

Stainless Steel Sculptures vs. Bronze Sculptures vs. Fiberglass Sculptures

Material Properties

- Bronze Sculpture

Copper is an excellent conductor of electricity and heat, offering good ductility and malleability. However, its corrosion resistance is relatively weak, making it prone to oxidation and rusting, thus requiring regular maintenance.

- Fiberglass Sculpture

Fiberglass is a composite material composed of glass fibers and resin, characterized by its lightweight, high strength, and corrosion resistance. However, it exhibits relatively poor heat resistance and wear resistance, and is prone to aging.

- Stainless Steel Sculpture

Stainless steel possesses outstanding corrosion resistance, heat resistance, and wear resistance. It maintains excellent condition over extended periods in harsh environments and requires low maintenance costs.

Technical Difficulty

- Bronze Sculpture

The production process for bronze sculptures is relatively complex, particularly the casting technique, which demands advanced technical expertise and equipment support. Surface treatment for bronze sculptures is also intricate, requiring multiple steps such as polishing and electroplating.

- Fiberglass Sculpture

The production process for fiberglass sculptures is relatively straightforward, primarily achieved through mold forming, making it suitable for large-scale sculptures. However, surface treatment for fiberglass sculptures is complex, requiring multiple rounds of sanding and coating.

- Stainless Steel Sculpture

The production process for stainless steel sculptures is relatively simple, with both forging and casting techniques capable of achieving intricate forms. Surface treatment is relatively easy, with sanding and polishing sufficient to achieve excellent results.

Cost

- Bronze Sculptures

The high cost of copper combined with complex production techniques results in relatively high costs for bronze sculptures.

- Fiberglass Sculptures

Fiberglass materials are relatively inexpensive, and the production process is simpler, leading to lower overall costs.

- Stainless Steel Sculptures

Compared to the other two, stainless steel materials fall in the middle price range. However, the production process is relatively straightforward, resulting in comparatively lower costs.

Visual Effect

- Bronze Sculptures

Bronze sculptures possess a unique texture and luster. After electroplating, they can exhibit various colors such as gold and bronze, holding significant artistic value.

- Fiberglass Sculpture

Fiberglass sculptures are lightweight and highly durable, making them suitable for large-scale installations. However, their surface texture and luster are relatively muted, requiring painting to enhance visual impact.

- Stainless Steel Sculpture

Stainless steel custom sculptures possess a modern aesthetic and lustrous finish. When polished, they can achieve a mirror-like effect, making them well-suited for contemporary architecture and environments.

The Significance of Stainless Steel Sculptures

Artistic Value

As an art form, stainless steel large scale sculptures possess unique artistic value. They combine the characteristics of modern materials with the artistry of traditional sculpture, capable of expressing diverse styles and themes. The surface treatment and form design of stainless steel abstract sculptures can be customized according to different environments and requirements, making them distinctive works of art.

Cultural Value

Stainless steel decorative statues for hotels hold significant cultural value within hotel environments. They not only enhance the artistic ambiance of a hotel but also convey its cultural philosophy and brand values. Through the design and themes of sculptures, hotels can showcase their unique cultural characteristics and sophisticated taste to guests.

Practical Value

The corrosion resistance, high-temperature tolerance, and wear resistance of stainless steel mirror polished sculptures confer substantial practical value. They maintain excellent condition outdoors over extended periods with minimal maintenance, reducing upkeep costs. Simultaneously, their modern aesthetic and lustrous finish seamlessly integrate with contemporary architecture and surroundings, elevating the hotel’s overall image.

Application of Stainless Steel Sculptures in Hotel Signage

Hotel Entrance

The hotel entrance is the first impression area for guests. Placing stainless steel sculptures here serves both as a guide and a distinctive marker. Metal modern sculpture designs can resonate with the hotel’s architectural style and cultural ethos, enhancing its recognizability and appeal. For instance, a large-scale stainless steel sculpture can be designed as an iconic landmark, allowing guests to spot the hotel’s location from afar.

Hotel Lobby

As a vital public space, the lobby gains artistic ambiance and cultural depth through stainless steel 3D custom statues. Designs can incorporate hotel-themed motifs—such as brand logos or cultural symbols—to reinforce brand identity. Simultaneously, sculptures serve as focal points, capturing guests’ attention and elevating the lobby’s visual impact.

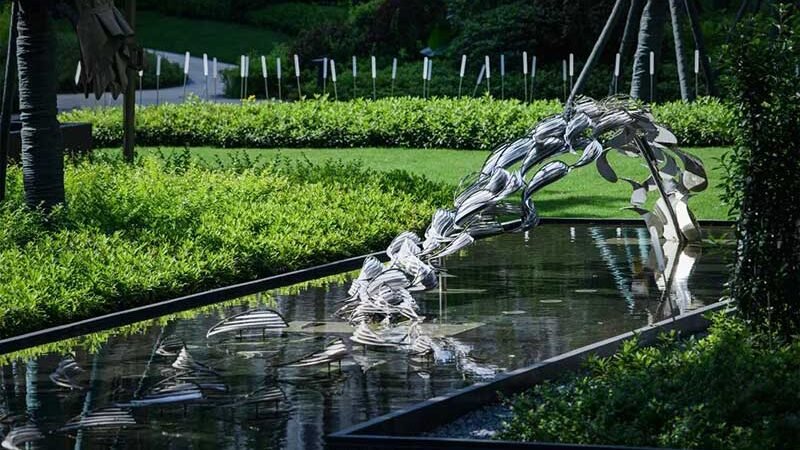

Hotel Garden

The hotel garden serves as a leisure and relaxation area for guests. Placing art custom stainless steel sculptures for public space here adds artistic flair. Sculptures can be designed to blend with the natural environment, such as animal or plant forms, enhancing the garden’s natural and artistic appeal. Simultaneously, sculptures can function as focal points within the garden, guiding guests’ sightlines and elevating the garden’s aesthetic appeal.

JYF METAL: The Premier Choice for Stainless Steel Sculptures

JYF METAL has established an excellent reputation in the field of custom stainless steel products for decoration through its outstanding quality and exquisite craftsmanship. JYF METAL’s sculptures not only possess a modern aesthetic and lustrous finish but can also be customized to meet client requirements, accommodating diverse environments and themes. With meticulous craftsmanship, every stage from design to production undergoes rigorous quality control, ensuring each piece achieves the highest artistic standards and practical value. Choosing JYF METAL means choosing quality and trust.

Conclusion

Large custom stainless steel outdoor sculptures, with their unique material properties and exquisite craftsmanship, stand as the premier choice for hotel signage. They not only exude a modern aesthetic and lustrous finish but also maintain excellent condition over time with minimal maintenance requirements. Through forging and casting techniques, stainless steel sculptures can achieve intricate forms and designs, catering to diverse environmental and thematic demands.

Compared to bronze and fiberglass sculptures, stainless steel sculptures demonstrate significant advantages in corrosion resistance, high-temperature tolerance, and wear resistance, while also offering relatively lower costs. Their application in hotel signage not only elevates the artistic ambiance and cultural depth of the establishment but also enhances its distinctiveness and appeal.

Choosing JYF METAL ensures you receive exceptional stainless steel sculptures that add unique artistic charm and premium sophistication to your hotel.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions