Stainless Steel Honeycomb Cladding: Modern Solution for Durable and Elegant Facades

Table of Contents

In the realm of modern architecture, material selection not only concerns structural integrity but also embodies design aesthetics and environmental sustainability. With continuous technological advancements and the pursuit of high-quality living, building materials are undergoing constant innovation and upgrading. As an emerging architectural material, stainless steel honeycomb cladding is gradually becoming the preferred choice for many designers and builders due to its unique structure and exceptional performance.

This article will delve into the construction, advantages, selection methods, and practical application cases of stainless steel honeycomb cladding, providing you with a comprehensive and in-depth understanding to help you make more informed choices in your projects.

Construction of Stainless Steel Honeycomb Cladding

Integration of Stainless Steel Cover Plates with Aluminum Honeycomb Cores

- Definition

Stainless steel honeycomb cover plates are fabricated by bonding stainless steel panels to aluminum honeycomb cores using advanced adhesive technology. The stainless steel panels provide robust external protection through their exceptional corrosion resistance and high strength, while the aluminum honeycomb cores impart excellent compressive strength, sound insulation, and thermal insulation properties due to their lightweight yet high-strength characteristics.

- Features

This unique structural design enables stainless steel honeycomb wall cladding to meet architectural functional requirements while achieving efficient material utilization. The stainless steel panels typically employ 304 or 316 stainless steel, both materials excelling in corrosion resistance and strength to withstand diverse harsh environments. The aluminum honeycomb core undergoes precise manufacturing processes to ensure uniform cell dimensions and structural stability, thereby delivering outstanding mechanical properties.

Production Process and Quality Control

- Production Process

The manufacturing of stainless steel honeycomb panel involves multiple stages, with each step—from raw material selection to finished product inspection—being critical. Advanced production techniques ensure the gratings’ flatness, dimensional accuracy, and bonding strength. High-quality stainless steel and aluminum honeycomb cores form the foundation of material selection. During production, automated equipment performs high-precision cutting, forming, and bonding to guarantee consistent quality for every grating.

- Quality Control

Rigorous standard inspections, including dimensional checks, strength testing, and corrosion resistance evaluations, guarantee each panel meets design specifications.

- Stainless steel honeycomb cladding combines corrosion resistance with lightweight and high strength, achieving a perfect balance between high performance and material properties.

Benefits of Stainless Steel Honeycomb Cladding

High Strength and Lightweight Design

The aluminum honeycomb core structure of stainless steel honeycomb cladding system offers an exceptionally high strength-to-weight ratio. Under identical load-bearing conditions, its weight is only a fraction of traditional solid materials, significantly reducing structural load and construction costs in architectural applications. Simultaneously, the high-strength stainless steel panels ensure the cladding durability and stability in harsh environments.

For instance, in large-scale public building applications such as roofs and floors, this lightweight design not only reduces structural load but also lowers transportation and installation costs.

Corrosion Resistance and Weathering Performance

Stainless steel inherently possesses outstanding corrosion resistance, maintaining long-term stability in diverse harsh natural environments. Whether in humid coastal regions or industrial settings with frequent chemical exposure, stainless steel honeycomb gratings demonstrate exceptional durability, significantly reducing maintenance costs and replacement frequency. This corrosion resistance not only extends the grating’s service life but also ensures the enduring aesthetic appeal of architectural exteriors.

Soundproofing and Thermal Insulation Performance

The porous structure of aluminum honeycomb cores effectively absorbs and reflects sound waves, delivering superior sound insulation. Additionally, this structure efficiently blocks heat transfer, enabling the panels to excel in thermal insulation. Incorporating stainless steel honeycomb panels in buildings significantly improves indoor acoustic and thermal environments, enhancing comfort for occupants and users.

For instance, in settings with high acoustic and thermal requirements – such as schools, hospitals, and office spaces – the application of stainless steel architectural honeycomb cladding substantially elevates user experience.

- Its high strength, light weight, corrosion resistance, sound insulation and flexible and beautiful characteristics, so that this material in the architectural design shows the advantages of excellence.

How to Select Stainless Steel Honeycomb Cladding

Material Quality

Selecting high-quality stainless steel and aluminum honeycomb cores is crucial for ensuring grating performance. Premium stainless steel should exhibit excellent corrosion resistance and strength, while aluminum honeycomb cores must feature uniform cell dimensions and high-strength bonding properties. When selecting materials, request suppliers to provide material test reports and quality certifications.

For instance, 304 and 316 stainless steel are commonly used in construction applications, demonstrating outstanding corrosion resistance and strength.

Production Process

Advanced production processes ensure the flatness, dimensional accuracy, and bonding strength of manhole covers. When selecting suppliers, evaluate their production equipment and process flows to confirm compliance with project requirements.

For instance, suppliers utilizing automated production lines typically deliver higher-quality products. The sophistication of production processes not only impacts cover quality but also influences service life and performance characteristics.

Customization Capabilities

Due to the diversity and complexity of construction projects, cover plates often require custom dimensions, shapes, and surface treatments. Therefore, selecting a supplier with robust customization capabilities is crucial.

Suppliers should be able to rapidly and accurately produce products that meet project requirements based on customer-provided drawings and specifications. Customization capabilities not only demonstrate a supplier’s technical proficiency but also reflect their responsiveness to customer needs.

After-Sales Service

Robust after-sales support provides crucial backing for projects. When selecting suppliers, it is essential to understand the scope of their after-sales services and response times. Key considerations include whether the supplier offers installation guidance, quality assurance, and the responsiveness of their after-sales support team.

High-quality after-sales service ensures prompt resolution of issues encountered during operation, thereby minimizing the risk of project delays and cost overruns.

- Premium materials, advanced manufacturing techniques, customization capabilities, and comprehensive after-sales support are the key elements ensuring the quality of stainless steel honeycomb gratings and the successful implementation of projects.

Application Cases of Stainless Steel Honeycomb Cladding

Building Roofs

Stainless steel honeycomb panel is widely used in building roofs due to its lightweight and high-strength properties. It can withstand harsh weather conditions while providing excellent thermal insulation and soundproofing. In some modern buildings, stainless steel honeycomb grating is also designed as a roof system integrated with solar panels, further enhancing the building’s energy efficiency.

For instance, in large commercial buildings and industrial facilities, the use of stainless steel honeycomb grating system not only reduces structural load but also improves the overall performance of the building.

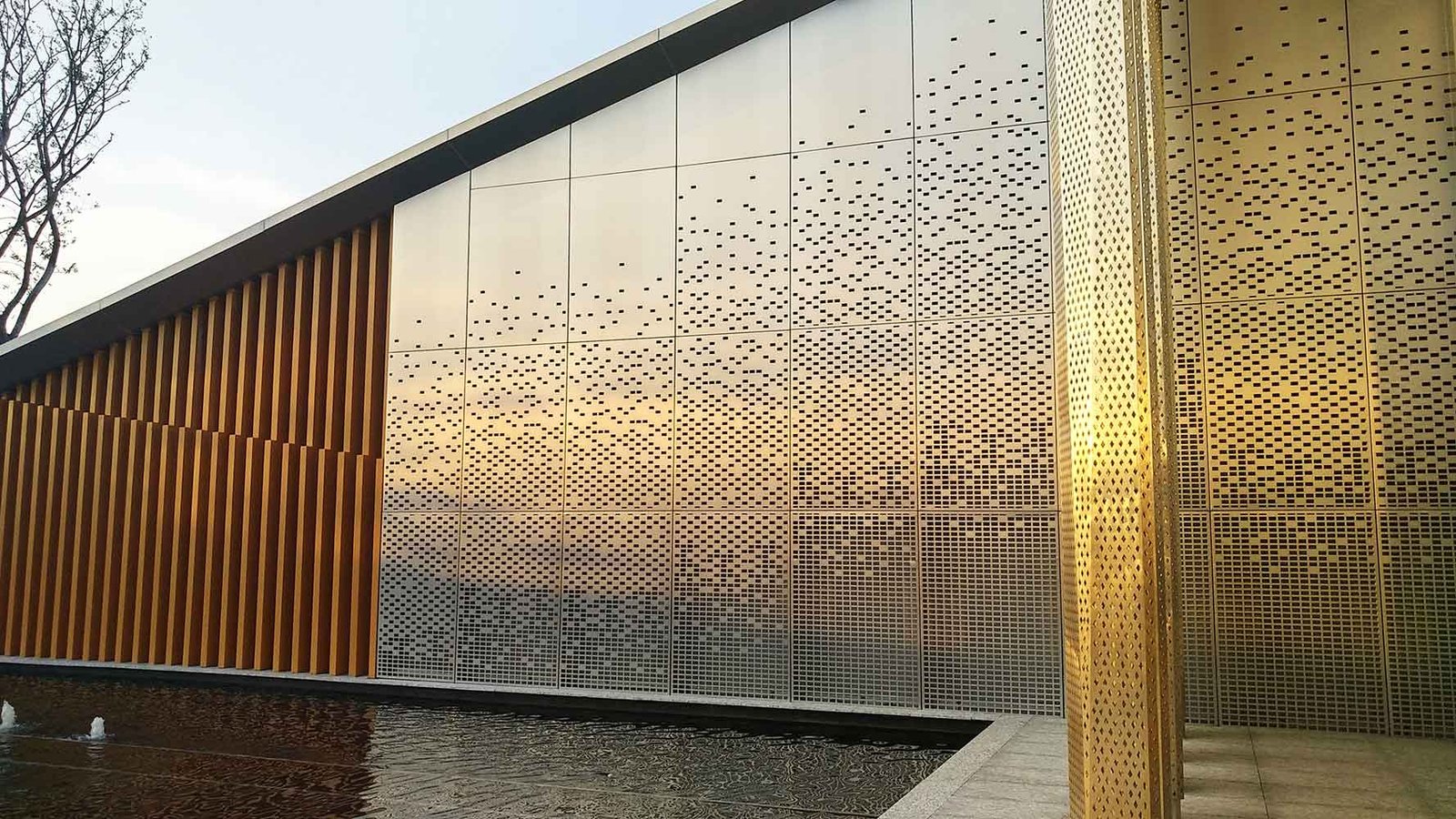

Building Facades

In building facade applications, custom PVD Coated honeycomb panels for Interior Wall Decoration not only provide an aesthetically pleasing appearance but also protect building structures from external environmental impacts. Their diverse surface treatments enable seamless integration with various architectural styles, adding distinctive visual appeal to structures.

For instance, in high-end residential and commercial buildings, the use of brushed finish stainless steel honeycomb panels enhances both the building’s visual appeal and structural durability.

Interior Decoration

The modern aesthetic and visual appeal of stainless steel honeycomb panels make them an ideal choice for interior decoration. They can be used to create partitions, ceilings, and wall coverings, imparting a clean and sophisticated visual impression to indoor spaces. Additionally, their excellent soundproofing and thermal insulation properties enhance indoor comfort.

For instance, in high-end hotels and office spaces, the application of stainless steel honeycomb panels not only elevates the quality of the environment but also improves the user experience.

- The application in roofing, exterior walls, and interior decoration fully demonstrates outstanding performance, aesthetic appeal, and versatility.

Maintenance and Care of Stainless Steel Honeycomb Cladding

Daily Cleaning

The surface of durable stainless steel honeycomb composite sheet should be cleaned regularly to maintain its appearance and performance. Use mild detergents and soft cloths for wiping, avoiding cleaners containing corrosive ingredients to prevent surface damage. Regular cleaning not only removes dust and grime but also prevents stain buildup, extending the grating’s service life.

Regular Inspections

Conduct regular inspections of the cover plate’s connection points and surface condition to promptly identify and address potential issues. For example, check for loose bolts, surface scratches, or corrosion. Regular inspections ensure the structural integrity of the cover plate, enable timely detection and repair of problems, and prevent issues from escalating.

Professional Maintenance

For complex maintenance tasks, it is recommended to engage a professional maintenance team. For instance, when dealing with large-area covers or covers in specialized environments, a professional team can provide comprehensive maintenance services to ensure long-term stable operation. Professional maintenance not only extends the service life of covers but also enhances their performance.

- Regular cleaning, inspection, and professional maintenance are essential measures to ensure the aesthetic appeal, performance, and long-term stability of stainless steel honeycomb panels.

Conclusion

Stainless steel honeycomb cladding panel, with its unique construction, multifaceted advantages, and extensive applications, is becoming an indispensable material in modern architecture. Selecting high-quality stainless steel honeycomb grating not only enhances a building’s aesthetics and functionality but also reduces long-term maintenance costs.

JYF METAL is committed to providing customers with high-performance stainless steel honeycomb cladding solutions through exceptional product quality and professional service, ensuring the success of your projects.

Through this detailed overview, we believe you now have a comprehensive understanding of stainless steel honeycomb grating. We hope this information empowers you to make more informed decisions for your future projects.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions