Stainless Steel Copper-Plated Sheet: A Blend of Performance and Aesthetics

Table of Contents

In today’s era of rapid development of material science, stainless steel copper-plated sheet has gradually become a star material in the field of industrial manufacturing and architectural decoration that has attracted much attention due to its unique performance and wide range of application prospects.

It not only inherits the robustness and durability of stainless steel, but also combines the excellent conductivity and decorative properties of copper, which brings a brand-new solution for modern industry and architecture.

Definition & Process

What is Stainless Steel Copper Plated Sheet ?

Stainless steel copper plated sheet is a composite material that is coated with a layer of copper on the surface of a stainless steel substrate through a water plating process. The manufacturing process of this material requires fine process control to ensure the uniformity and adhesion of the copper layer.

Stainless steel, as the base material, provides high strength and corrosion resistance, while the copper layer gives the material excellent electrical, thermal and decorative properties. This composite structure makes the stainless steel copper-plated plate combine the advantages of both materials in performance, while avoiding the limitations of a single material.

How is Stainless Steel Copper Plated Sheet Produced ?

The production process of copper tone stainless steel sheet mainly includes three steps: surface pretreatment, water plating and post-treatment.

• The stainless steel substrate needs to undergo rigorous surface cleaning and activation treatment to remove surface impurities and oxidized layer, to ensure that the plating layer can be firmly attached to the substrate.

• Copper ions are uniformly deposited on the stainless steel surface through the aqueous plating process to form a homogeneous copper plating layer.

• The corrosion and abrasion resistance of the plating layer is further improved by appropriate post-treatment processes, such as passivationtreatment or coating with a protective film.

Stainless Steel Copper Plated Sheet VS. Copper Plate

Performance Comparison

Strength and Hardness

Stainless steel copper plated sheet: The stainless steel base material itself has high strength and hardness, and is able to withstand large mechanical stresses. Although the copper-plated layer is relatively soft, it has less impact on the overall strength due to its thin thickness. As a result, copper-plated stainless steel sheets excel in strength and hardness and can meet the needs of most industrial and architectural applications.

Copper Plate: Copper plate has relatively low strength and hardness and is prone to deformation especially when subjected to high mechanical stress. Although copper has better ductility, its performance is not as good as that of stainless steel copper-plated sheet in some occasions where high strength support is required.

Corrosion Resistance

Stainless steel copper plated sheet: Stainless steel has excellent corrosion resistance and is able to maintain stable performance in a wide range of harsh environments. Although the copper plating layer increases the corrosion resistance of the material to a certain extent, the main corrosion resistance still relies on the stainless steel substrate. Through appropriate post-treatment processes, such as passivation treatment, can further improve the corrosion resistance of copper-plated layer.

Copper plate: Copper itself has a certain degree of corrosion resistance, but in the humid environment is prone to the formation of copper green, resulting in surface corrosion. The corrosion resistance of copper mainly depends on the oxide film formed on its surface, but in some strong acid and alkali environments, the corrosion resistance of copper will be significantly reduced.

Electrical and Thermal Conductivity

Stainless steel copper plated sheet: The addition of the copper layer significantly improves the electrical and thermal conductivity of stainless steel. Since the electrical and thermal conductivity of copper is much higher than that of stainless steel, even if the plating layer is thin, it can effectively improve the electrical and thermal conductivity of the material. This makes the 304 grade copper plated stainless steel sheet has a wide range of application prospects in the field of electronic, electrical and heat exchange.

Copper plate: Copper is a material with excellent electrical and thermal conductivity, and its electrical and thermal conductivity are among the highest of all metals. However, the low strength and hardness of copper plate limits its application in some occasions where high strength support is required.

Wear Resistance

Stainless steel copper plated sheet: Stainless steel substrates have better wear resistance and can effectively resist surface abrasion. Although the copper plating layer is relatively soft, it has less impact on the overall wear resistance due to its thin thickness. The abrasion resistance of the copper plating layer can be further improved by appropriate post-treatment processes, such as coating protective film.

Copper plate: Copper has relatively poor abrasion resistance and is prone to wear in environments with high friction. Although the abrasion resistance of copper plate can be improved by surface treatment, its abrasion resistance is still inferior to that of anti-fingerprint copper finish stainless steel panel.

Cost Comparison

Raw Material Cost

Stainless steel copper plated sheet: Stainless steel and copper are both common metal materials with relatively stable prices. The raw material cost of copper plated stainless steel plate mainly depends on the price ratio of stainless steel and copper. Due to the thin copper plating layer, the amount of copper is relatively small, so the raw material cost is relatively low.

Copper plate: copper is a precious metal, its price is relatively high. The raw material cost of copper plate mainly depends on the price of copper, so in the case of the same thickness and area, the raw material cost of copper plate is significantly higher than that of copper stainless steel wall cladding for commercial interiors.

Processing Cost

Stainless steel copper plated sheet: 4×8 copper brushed stainless steel sheet’s processing process is relatively complex, requiring a number of steps such as surface pretreatment, plating and post-treatment. Although the processing cost is higher, the comprehensive cost is still competitive due to its lower raw material cost.

Copper plate: The processing process of copper plate is relatively simple, which is mainly realized through machining and surface treatment. However, due to the low hardness of copper, it is easy to be deformed during processing, requiring higher machining precision and stricter process control. Therefore, the processing cost of copper plate is relatively high.

Maintenance Cost

Stainless steel copper plated sheet: Stainless Steel Copper Plated Sheet has good corrosion and abrasion resistance and low maintenance cost. Under normal use conditions, only regular cleaning of the surface is required to maintain its performance and appearance.

Copper plate: Copper plate is prone to formation of patina in humid environments and requires regular surface cleaning and maintenance. In addition, copper plates are prone to corrosion in some strong acid and alkali environments, requiring additional anti-corrosion measures and increasing maintenance costs.

Application Fields

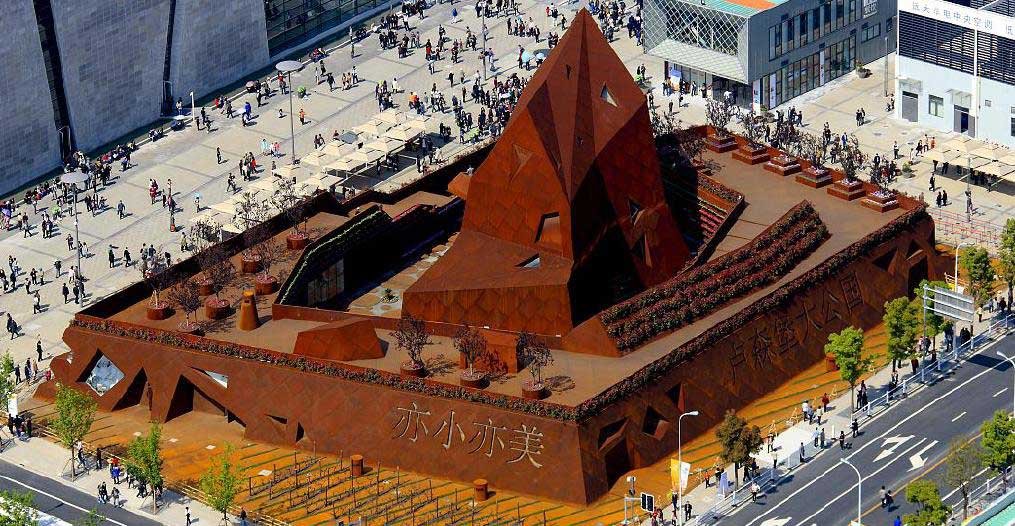

Architectural Decoration

Copper stainless steel sheet for interior wall cladding has a wide range of applications in the field of architectural decoration. It can be used to make curtain walls, hands and other building components, not only beautiful and durable, but also can effectively resist the erosion of harsh environments.

Compared with traditional stainless steel materials, stainless steel copper-plated plate has a better decorative effect, which can add a unique vintage artistic flavor to the building. In addition, its corrosion and abrasion resistance also enable it to maintain good appearance and performance during long-term use.

Machinery Manufacturing

Copper-coated SS sheet for electrical equipment housing has a wide range of applications in the field of machinery manufacturing. Its high strength and wear resistance enable it to withstand large mechanical stress and friction, and it is suitable for making mechanical parts, molds, tools and so on.

For e.g., in the manufacture of molds, stainless steel copper-plated plate can be used to make the electrode part of the mold, which can improve the processing accuracy and service life of the mold.

Conclusion

Customized copper stainless steel sheet for design projects, as a new type of composite material, is gradually changing the face of modern industry and architecture with its unique properties and wide application prospects.

It not only inherits the high strength and corrosion resistance of stainless steel, but also combines the excellent electrical conductivity and decorative properties of copper, which provides a brand new solution for modern industry and architecture.

In comparison with copper plate, stainless steel copper-plated plate excels in strength, hardness, corrosion resistance and abrasion resistance, and also has certain advantages in cost.

Its wide application in many fields such as architectural decoration, electrical and electronic, machinery manufacturing, aerospace and so on, further proves its excellent performance and value.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions