Rapid Proofing: How to Accelerate Project Progress

Table of Contents

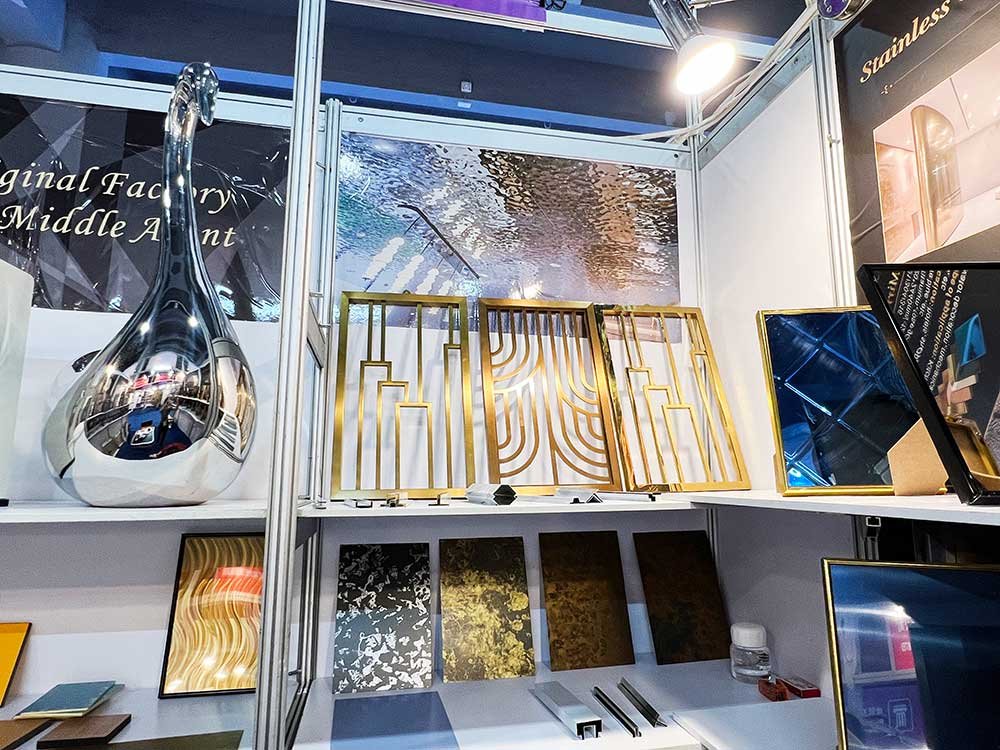

In the competitive world of manufacturing, especially for stainless steel products, the ability to quickly produce high-quality samples is crucial for accelerating project progress. At JYF Metal, we specialize in providing rapid proofing services for a range of stainless steel products, including stainless steel color sheets, stainless steel water ripple sheets, stainless steel decorative profiles (or stainless steel tile trim), and metal screen partitions (or metal room dividers). Our commitment to quality and efficiency ensures that we can meet and exceed client expectations.

The Importance of Rapid Proofing in Project Progress

Rapid proofing is a transformative approach that allows manufacturers to create physical samples of their products swiftly. This process is particularly vital for stainless steel products, which often require intricate designs and high precision. By producing samples quickly, companies can identify and address potential issues early, gather valuable feedback, and refine their products before full-scale production begins.

For instance, creating a sample of a stainless steel water ripple sheet can help identify any design flaws or manufacturing challenges before committing to large-scale production. This not only saves time but also reduces costs associated with rework and delays.

Our Approach to Rapid Proofing

Stainless Steel Color Sheets

At JYF Metal, we maintain a selection of conventional stainless steel color sheets that can meet the majority of client requirements. These standard samples allow us to provide quick and efficient solutions, ensuring that clients receive the materials they need without delay.

However, for clients with unique color requirements, our dedicated team of experienced color technicians ensures that we can achieve a match with up to 90% accuracy. Our team is highly skilled in adjusting color shades and tones to meet specific client needs, providing a personalized solution that aligns with their vision.

Stainless Steel Decorative Profiles

Our state-of-the-art equipment, including shearing, bending, and slotting machines, combined with advanced laser cutting technology, allows us to produce stainless steel decorative profiles with precise dimensions and shapes. This ensures that the samples we provide meet the exact specifications required by our clients.

By focusing on precision and accuracy, we can deliver high-quality decorative profiles that not only meet aesthetic requirements but also ensure structural integrity and functionality.

Metal Screen Partitions

Producing metal screen partitions requires a high level of craftsmanship, particularly in welding and polishing. Our skilled technicians pay meticulous attention to detail, ensuring that even small-scale partitions are produced with the same level of quality as larger ones.

We understand that the intricacies of design and pattern aesthetics are crucial for these products. Our team ensures that every aspect of the partition, from the welding to the final polish, is executed to the highest standard, resulting in a product that is both functional and visually appealing.

Strategies to Accelerate Project Progress with Rapid Proofing

Leverage Advanced Manufacturing Technologies

Precision laser cutting technology is a cornerstone of our rapid proofing process. It allows us to create intricate designs and custom shapes with high accuracy and consistency. This technology is particularly useful for producing detailed metal screen partitions or unique stainless steel decorative profiles. By using precision laser cutting, we can significantly reduce the time required to produce high-quality samples.

Optimize Design Processes

Optimizing the design process is essential for efficient proofing. Using computer-aided design (CAD) software, our designers create detailed and accurate models of stainless steel products before they are manufactured. This enables virtual testing and evaluation, helping to identify potential issues early and make necessary adjustments before physical prototypes are created.

Involving clients and stakeholders early in the design process also streamlines the proofing phase. By gathering feedback and incorporating it into the design from the outset, we can reduce the need for multiple iterations of prototypes, saving time and resources.

Implement Efficient Communication Channels

Effective communication is crucial for ensuring that all parties involved in the proofing process are aligned. Implementing efficient communication channels, such as project management software or real-time collaboration tools, allows our teams to quickly share updates, feedback, and changes. This reduces the risk of miscommunication and delays.

For example, when working on a project involving custom stainless steel tile trim, clear and timely communication between the design team and the production team ensures that the final product meets the client’s specifications and is delivered on time.

Focus on Quality Control

Quality should never be compromised for speed. Implementing rigorous quality control measures throughout the proofing process ensures that each sample meets the highest standards. Regular inspections, testing, and evaluations help identify any defects or issues early on.

For stainless steel products, this may involve checking for surface finish, dimensional accuracy, and material integrity. By maintaining a focus on quality, we can avoid costly rework and delays, ultimately leading to faster project progress.

Streamline Supply Chain Management

The efficiency of the supply chain can significantly impact the speed of the proofing process. Working closely with suppliers and partners ensures that materials and components are delivered promptly and meet the required specifications.

For example, when producing stainless steel color sheets, having a reliable supply of high-quality stainless steel raw materials is crucial. Establishing strong relationships with suppliers and implementing efficient inventory management systems reduces lead times and ensures that production can proceed without interruptions.

Embrace a Culture of Continuous Improvement

Fostering a culture of continuous improvement within the organization drives innovation and efficiency in the proofing process. Encouraging employees to share ideas and feedback, and regularly reviewing and refining processes, leads to ongoing improvements in speed and quality.

For instance, after completing a project involving metal screen partitions, conducting a post-project review to identify areas for improvement can inform future projects and streamline the proofing process.

Beyond Just Meeting Requirements

At JYF Metal, we understand that rapid proofing is not just about creating a sample that matches a client’s request or an existing sample. We go beyond this by considering the subsequent production challenges, rationalization of structure and design, and the feasibility of various manufacturing processes. Our team evaluates which production methods are most suitable and acceptable to the client, ensuring that the final product is not only a perfect match but also efficiently producible at scale.

Case Study: Accelerating Project Progress with Rapid Proofing

To illustrate the benefits of rapid proofing, consider a company specializing in stainless steel decorative profiles. They were approached by a client with a unique design concept for a custom metal room divider. Using advanced CAD software, the design team created a detailed virtual model of the product, which was reviewed and approved by the client.

The production team then utilized CNC machining and laser cutting technologies to create a high-quality prototype in just a few days. The prototype was tested and evaluated, with any necessary adjustments made quickly and efficiently. Thanks to rapid proofing, the final product was delivered to the client within a significantly shorter timeframe than traditional methods would have allowed.

Conclusion

Rapid proofing is a powerful tool for manufacturers of stainless steel products looking to accelerate project progress. By leveraging advanced manufacturing technologies, optimizing design processes, implementing efficient communication channels, focusing on quality control, streamlining supply chain management, and embracing a culture of continuous improvement, companies can create high-quality samples more quickly and efficiently.

At JYF Metal, we are committed to providing our clients with the highest quality stainless steel products and services. Our experienced team of designers, engineers, and production specialists work together to ensure that each project is completed efficiently and to the highest standard. Contact us today to learn more about our rapid proofing capabilities and how we can help bring your stainless steel product ideas to life.

If you want to know more about stainless steel samples, check out our top blog !

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions