Precision Sheet Metal Fabrication: The Secret to Crafting Perfect Metal Enclosures

Table of Contents

In manufacturing, precision sheet metal fabrication plays a crucial role in creating high-quality metal enclosures. Whether for electronics, automotive, aerospace, or industrial machinery, transforming raw metal sheets into functional, durable, and visually appealing enclosures requires advanced technology, expert craftsmanship, and attention to detail. At JYF METAL, we specialize in this process. In this post, we’ll explore the key techniques and materials that allow us to create perfect enclosures, setting us apart in the industry.

Material Selection: The Key to Superior Enclosures

- Stainless Steel

Renowned for its corrosion resistance, strength, and aesthetic appeal, stainless steel is ideal for applications requiring durability and a polished finish. Its resistance to rust and stains makes it perfect for harsh environments such as medical equipment, food processing, and outdoor installations. Stainless steel is also easy to clean and maintain, ensuring longevity and pristine appearance.

- Aluminum

Light yet strong, aluminum is often selected for applications where weight is critical, such as in aerospace or automotive sectors. Its excellent resistance to corrosion and ease of machining make it a versatile option.

- Carbon Steel

Carbon steel offers high strength at a more affordable price, making it ideal for industrial machinery and structural components. However, it requires protective coatings to safeguard against rust.

At JYF METAL, we prioritize stainless steel for many projects, as it balances versatility and reliability. By selecting the right grade, we ensure that our enclosures meet both functional and aesthetic needs.

The Fabrication Process: From Concept to Completion

Cutting: Precision from the Start

The first step in sheet metal fabrication is cutting. At JYF METAL, we primarily use two methods: shearing and laser cutting.

- Shearing

This method uses a shear machine to make straight cuts in flat sheets, ideal for dividing large sheets into smaller pieces. It’s efficient and cost-effective, perfect for initial cuts.

- Laser Cutting

For more intricate designs, laser cutting is the method of choice. A high-powered laser melts the metal, creating precise, clean cuts with minimal waste. This method excels at producing fine details and complex shapes, offering unrivaled precision.

Bending and Forming: Shaping Metal with Accuracy

Once the sheets are cut, the next step is bending and forming. At JYF METAL, we focus on notching (grooving) to improve bending accuracy.

- Notching (Grooving)

By creating small grooves in the sheet before bending, we achieve tighter, more precise bends. This technique is essential for creating complex shapes and ensures a perfect fit for every enclosure.

- V-Bending

The most common bending technique, where a punch forces the metal into a V-shaped die. This process allows us to control the bend angle for accuracy.

Welding: Joining Metal with Strength

Welding is vital for enclosures requiring multiple metal pieces. At JYF METAL, we specialize in both spot welding and full welding.

- Spot Welding

Spot welding joins metal sheets at specific points where they overlap. It’s fast, efficient, and ideal for high-volume production, creating strong joints when done by experienced technicians.

- Full Welding

Full welding creates a continuous bond along the joint, providing enhanced strength. This method is critical for enclosures that need to endure heavy use or harsh conditions.

Grinding and Finishing: Refining the Surface

After cutting, bending, and welding, the next step is to refine the surface. Grinding, sanding, and polishing ensure a smooth, flawless finish.

- Grinding

This process removes excess material and smooths rough edges, preparing the surface for painting or coating.

- Sanding

Sanding is a finer technique that uses abrasives to achieve a smooth, even surface.

- Polishing

For enclosures requiring a mirror-like finish, polishing is the final step. This process uses progressively finer abrasives to create a high-gloss surface.

Coating and Painting: Durability Meets Aesthetics

Coatings and paints enhance both the protection and appearance of metal enclosures. At JYF METAL, we favor PVD coating for its superior properties.

- PVD Coating (Physical Vapor Deposition)

This advanced technique involves vaporizing a material in a vacuum and depositing it onto the surface, creating a highly durable finish. PVD offers excellent corrosion resistance, a variety of colors, and is environmentally friendly. It’s ideal for applications where both appearance and performance matter, such as luxury electronics and automotive parts.

- Powder Coating

Powder coating applies a dry paint electrostatically and then cures it under heat, offering a durable finish in various colors.

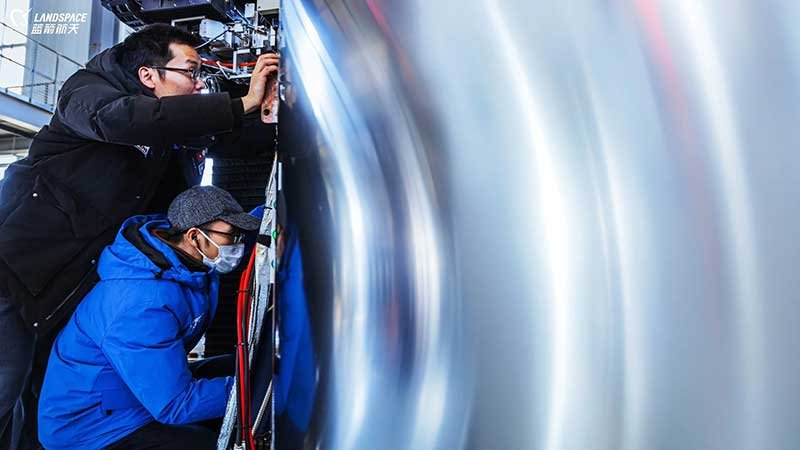

Quality Control: Ensuring Excellence

Throughout every step, quality control is essential. At JYF METAL, we conduct rigorous inspections to guarantee that each enclosure meets our high standards. This includes checks for dimensions, surface quality, and functionality, ensuring that our products are flawless.

Conclusion

Precision sheet metal fabrication is both a science and an art. It combines the understanding of materials, cutting-edge technology, and skilled craftsmanship. At JYF METAL, we take pride in transforming raw metal sheets into high-performance enclosures that meet the highest standards of quality.

From selecting premium stainless steel to the accuracy of laser cutting and notching, every step is carried out with care. Our expertise in welding and preference for PVD coating ensure that our enclosures are not only functional but also visually impressive.

If you’re looking for a reliable partner in precision sheet metal fabrication, reach out to JYF METAL today. Let us help you craft the perfect metal enclosure for your needs.

You Might Also Like

Please Share This

Follow Us On Twitter

On-site Installation of Stainless Steel Screen Partition

Precision-made. Professionally installed.

Transforming spaces with durable, elegant metal dividers.

📮DM us for custom design and project support.

#interiordecoration #metalpartition #roomdivider #sheetmetalfab

Café Design | A Sensory Collision of Metal and Coffee

This design is from BOUNDLESS SPACE DESIGN OFFICE

If you are interested in stainless steel decorative materials, please contact me for a quote !

Email: claire@jyfmetal.com

#interiordecoration #decorativematerials #metallic

Stainless Steel Fluted Panels & Skirting Boards

Clean lines, large size, premium finish — perfect for luxury interiors.

Custom colors, surface treatments, and dimensions available.

📩 DM us for catalogs or project solutions.

#flutedpanels #metalskirting