Patina Stainless Steel with Timeless, Durable Finishes

Table of Contents

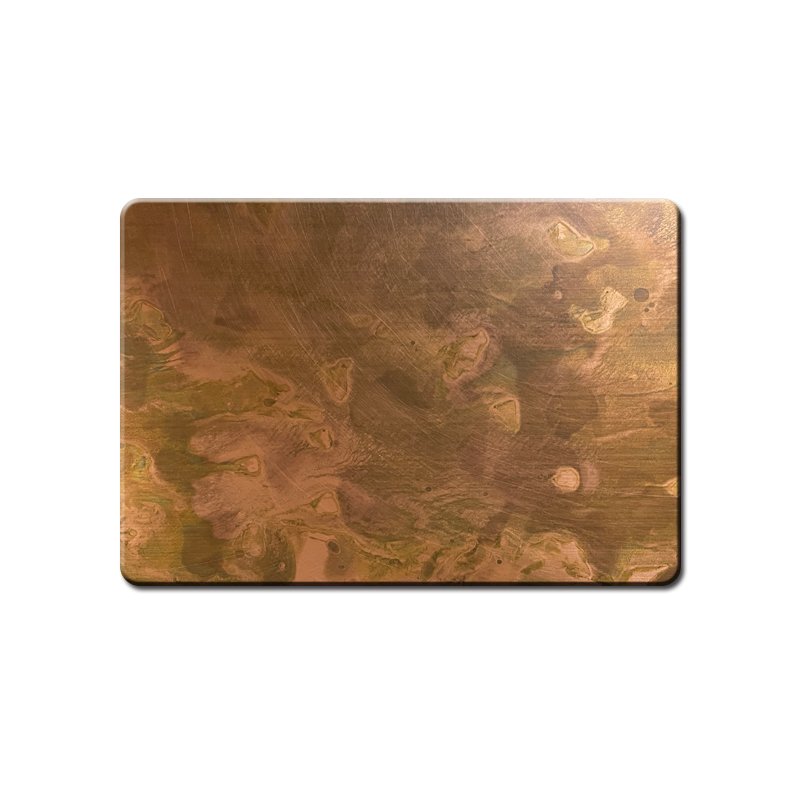

In modern architecture and interior design, the choice of material not only affects the visual effect, but also determines the quality and durability of the project. With its unique vintage texture and excellent performance, Patina Stainless Steel is gradually becoming a high-end material favored by designers and engineers. It displays a patina-like natural color through a special surface treatment process, combining the solidity of metal with the temperature of art.

JYF METAL’s patina finish is unique and designed to meet the different needs of our customers. Our solutions are both aesthetically pleasing and practical, ideal for decorative wall panels, cladding and customized furniture.

Unique Process of Patina Stainless Steel

The charm of patina stainless steel stems from the special treatment process of its surface imitating copper-green, which can simulate the copper-green effect formed by natural weathering, and can also be quickly realized by chemical treatment, giving stainless steel rich colors and textures.

Natural Weathering Method

Natural weathering method uses time and environmental factors to make the surface of stainless steel gradually form an oxidized layer similar to copper green. This method has a longer cycle, suitable for the pursuit of natural aging effect of the project. Weathering process, the environment of humidity, temperature, chemical composition in the air will affect the final color, so that each plate presents a unique texture and color.

Chemically Induced Method

To meet the efficiency needs of industrial production, chemically induced method is widely used. By applying a specific chemical solution to the surface of stainless steel, the oxidation reaction is accelerated rapidly to form a stable copper-green layer. This method is not only controllable, but also can adjust the color intensity and texture depth according to the formula to meet the customized needs of customers.

Surface Protection and Sealing

After the formation of the patina layer, in order to ensure that the color and texture of the surface is long-lasting, it is usually sprayed with a transparent protective layer or sealer to prevent excessive oxidation or environmental corrosion, as well as to ensure that the material is easy to clean and abrasion-resistant.

Process Overview:

- Surface pre-treatment: cleaning, degreasing and rust removal.

- Oxidation: natural weathering or chemical soaking

- Curing treatment: heating or standing to fix the color layer

- Protective coating: Anti-fingerprint treatment to protect the surface to a certain extent.

- Quality control and packaging

Through this series of steps, patina stainless steel not only presents a vintage aesthetic, but at the same time maintains the corrosion-resistant and high-strength properties of stainless steel itself.

The Wide Application of Patina Stainless Steel

Patina antique stainless steel is widely used in many fields such as building facade, interior decoration, furniture manufacturing and so on because of its beauty and functionality.

Building Facade

Patina stainless steel is widely used in the design of curtain walls, roofs and canopies of modern buildings. Its copper-green color brings a retro texture, which can inject a sense of time precipitation into the space and enhance the overall artistic level of the building.

Anti-corrosive: suitable for seaside or high humidity areas, lasting resistance to wind and rain erosion.

Color diversity: adjustable color shades according to design needs, creating unique visual effects.

Strong weather resistance: even if exposed to the outdoors for a long time, it still maintains a stable texture.

Interior Decoration

In interior design, patina stainless steel is widely used in wall panels, partition screens, ceiling decorations, etc., which can enhance the artistic sense of space and texture level.

Art wall: combined with copper green texture, to create a retro or industrial style space.

Partition screen: both practical and decorative functions, dividing space while adding aesthetic design.

Ceiling decoration: the fusion of metal texture and soft copper green color, increasing the sense of space levels.

Furniture and Decorations

Painted stainless steel is also used in high-end customized furniture such as tables, chairs and cabinets, as well as artistic sculptures and decorations. The combination of vintage texture and metal strength makes the furniture not only beautiful but also durable.

Furniture surfaces: unique textures for artistic furniture looks

Sculptural artwork: brings echoes of nature and history to indoor and outdoor spaces

Decorative elements: patina bronze color is rich, suitable for a variety of design styles.

The Advantages of Patina Stainless Steel

- Unique Visual & Tactile Experience – Lacquered stainless steel combines the hardness of the metal and the softness of the copper green, bringing visual artistic enjoyment and tactile texture experience, suitable for the pursuit of individuality and quality of the design project.

Excellent Corrosion Resistance & Weather Resistance – Even in harsh environments such as seashore and high humidity, lacquered stainless steel can still maintain stable performance and color, and long-term use without frequent maintenance.

- Low Maintenance Cost – The protective surface layer makes it difficult for stains to adhere, and easy to clean, greatly reducing the maintenance cost.

- Environmentally Sustainable – Using recyclable materials, the production process in line with environmental standards, in line with the concept of modern green building.

Future Development Trends of Lacquered Stainless Steel

Environmental Upgrading – The future chemical treatment will be more environmentally friendly, reducing the impact on the environment.

Diversified Customization – The color and texture will be richer, to meet the needs of more design styles.

Cross-border Integration – Combine with other materials such as wood and glass to form innovative composite materials.

Intelligent Manufacturing – With the help of intelligent equipment to improve process precision and production efficiency

JYF METAL's Production Strength and Service Advantages

As a leading stainless steel manufacturer in the industry, JYF METAL has a perfect production system and rich experience in customization, and is committed to providing customers with high-quality patina stainless steel products.

Advanced Production Equipment

JYF METAL is equipped with international advanced surface treatment equipment, which can accurately control the chemical treatment process to ensure that each batch of products has stable color and uniform effect. At the same time, the company has a strict quality inspection system to ensure that the performance and appearance of the material are in line with customer requirements.

Personalization & Customization

For different projects, JYF METAL provides customized services:

Color customization: according to the design drawings and customer needs to adjust the shade of copper and green and color changes.

Texture design: from delicate to rough surface texture can be realized.

Size: Flexible cutting and processing to meet diversified installation needs.

Fast Delivery & After-sales Guarantee

JYF METAL adopts environmentally friendly materials and processes, attaches importance to the recycling of resources, and strives to create a sustainable green manufacturing model.

Conclusion

With its unique artistic texture and excellent performance, lacquered stainless steel is bringing more possibilities for architectural, interior and furniture design. JYF METAL, with its advanced technology and professional customization service, helps customers realize their design dreams and promotes the wide application and development of lacquered stainless steel.

FAQ

What is patina stainless steel?

Patina Stainless Steel is a metal material that has been treated with a controlled corrosion or oxidation process to give it a surface that has been purposely designed to look like an antique, such as patina, rust, or bronze. This special visual effect brings a unique texture and layered aesthetic to the design.

How is the patina process achieved?

The Patina effect is usually achieved by applying a chemical reaction agent or by accelerating the oxidation process in a specific environment to create multiple layers of color and texture with depth on the stainless steel surface. It is a controlled “aging” art that gives modern metals a vintage and naturally oxidized appeal.

Is patina stainless steel durable?

Yes, it is. Although the surface is treated with a special process, the base material is still stainless steel, which maintains its high strength, corrosion and wear resistance. The oxidized or rusted effect on the surface creates a “second layer of protection” for long term stability in outdoor or high humidity environments.

How do I maintain the surface of patina stainless steel?

Routine cleaning is very simple, usually using water or a neutral detergent. Avoid acidic or abrasive cleaning products. For long-term protection, a special sealer can be applied every few years to maintain color and protection.

Can I customize the colors and effects of patina stainless steel?

Yes, JYF METAL offers flexible customization services in a variety of hues (copper green, blue-black, rust red, etc.), texture effects and surface patterns. Unique visual styles can be designed according to the project requirements, adapting to the individual expression of the architecture, interior or art installations.

Is patina stainless steel environmentally friendly?

Yes, the base material used in the Patina process is stainless steel and is 100% recyclable. Most rusting or oxidizing processes also have a very limited chemical demand on the environment and are overall consistent with sustainable design concepts.

Can patina stainless be used outdoors?

Yes. It is ideal for building facades, landscaping, curtain walls or other outdoor elements. The oxidized finish not only provides a unique aesthetic, but also enhances weathering and corrosion resistance against the elements and harsh climates.

Does the patina stainless steel finish change over time?

Yes. Over time, Patina surfaces may develop subtle color variations and shading levels, and this natural evolution is part of the aesthetic appeal that gives each project a unique “sense of time”.

Common Misconceptions and Risk Tips

In the actual use and maintenance of stainless steel panels, owners and builders of several common misconceptions deserve special attention.

JYF METAL will also remind contractors and general contractors to pay attention to the protection of finished products during the supply stage, and can provide additional services such as protective film and customized packaging.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions