mirror polished metal sheet

JYF Metal

Stainless Steel Mirror Polished Metal Sheet

One-stop Metal Decoration Engineering Service

About JYF Metal

One Of The Leading Manufacturer Of Decorative Stainless Steel Sheet In China

JYF Metal is a leading production service company located in Foshan, Guangdong Province, China. Founded in 2008, it specializes in metal materials, product development, design, manufacturing and installation. We provide a wide range of architectural metal solutions for contractors, design companies, elevator manufacturers, sheet metal fabricators, etc.

Custom Service

We have a professional team of engineers and designers to provide customers with the best quality and meet personalized requirements.

1 . How To Choose Material ?

201 stainless steel

Corrosion resistance: although the corrosion resistance of 201 than 304 and 316 slightly worse, but still enough to deal with most of the indoor daily environment.

Application: commonly used in indoor building decoration materials, and other do not require extreme corrosion resistance occasions.

304 stainless steel

Cost and performance: between cost and performance, 304 provides a good balance for applications that require corrosion resistance and certain mechanical properties.

Application: widely used in indoor and outdoor decoration, furniture, and medical equipment.

316 stainless steel

Cost: more expensive than the 304, it is typically used in more demanding environments, such as chemical processing equipment and marine applications.

Application: commonly used in marine environment, chemical equipment and medical equipment requiring very high corrosion resistance.

201/304/316 stainless steel mirror polished sheet is the most common in decorative sheet metal.

01

02

03

201 stainless steel

Corrosion resistance: although the corrosion resistance of 201 than 304 and 316 slightly worse, but still enough to deal with most of the indoor daily environment.

Application: commonly used in indoor building decoration materials, and other do not require extreme corrosion resistance occasions.

304 stainless steel

Cost and performance: between cost and performance, 304 provides a good balance for applications that require corrosion resistance and certain mechanical properties.

Application: widely used in indoor and outdoor decoration, furniture, and medical equipment.

316 stainless steel

Cost: more expensive than the 304, it is typically used in more demanding environments, such as chemical processing equipment and marine applications.

Application: commonly used in marine environment, chemical equipment and medical equipment requiring very high corrosion resistance.

2 . Color Selection of Stainless Steel Mirror Polished Metal Sheet

In the project, if the use of stainless steel mirror polished metal sheet, considering the elements of colored mirror finish plate, different colors of the sheets for the decoration will have a completely different effect.

Mirror stainless steel sheet, its surface can form a reflection, the surrounding scenery through the mirror image to create a projection to reflect the actual content in the form of a void. In engineering design, designers can expand the space and enhance the scene highlights by using mirrored stainless steel to form a sense of technology and the times.

Titanium gold mirror stainless steel sheet is based on stainless steel 2B plate polished into a mirror surface, using large vacuum coating equipment coated with a highly wear-resistant, corrosion-resistant golden yellow titanium nitride layer.

Champagne gold mirror polished stainless steel sheet is a combination of seductive, romantic champagne color and stainless steel, forming a light and luxurious, but not vulgar, sense of high class.

The black titanium mirror finish stainless steel sheet is very textured, a fashionable color with a mysterious feeling, suitable for many showrooms.

Sapphire blue stainless steel sheet is characterized by flamboyant, and is often the most eye-catching color in construction projects. In legend, the Goddess of Hope is based on a blue diamond. So a gem of blue is synonymous with hope.

Champagne-gold-mirror-stainless-steel-sheet

Titanium-gold-mirror-stainless-steel-sheet

Bronze-mirror-stainless-steel-sheet

Rose-gold-mirror-stainless-steel-sheet

Black-titanium-mirror-stainless-steel-sheet

Emerald-green-mirror-stainless-steel-sheet

Sapphire-blue-mirror-stainless-steel-sheet

Violet-mirror-stainless-steel-sheet

3 . Size and Thickness

Standard sheet sizes are typically 4 by 8 feet (about 1219 x 2438 mm) or 4 by 10 feet (about 1219 x 3048 mm), but other sizes can be customized to suit customer requirements. Sheet thickness generally ranges from 0.6 mm to 3.0 mm, depending on the engineering application.

4 . Packing and Transportation

Stainless steel sheets are usually packed in wooden pallets or cases to ensure safety during transport. Packaging can also be adjusted according to the specific needs of customers.

Specification of Stainless Steel Mirror Polished Metal Sheet

Standard:JIS/AISI/ASTM/GB/DIN/EN

Type:Cold rolling

Thickness:0.3-3.0mm

Grade:201/304/316/430 etc…

Width:1000/1220/1500mm

Surface:BA、2B polishing+PVD coating

Length:2000/2440/3050mm (customizable)

Color:Titanium, sapphire blue, bronze, emerald green etc…

Thickness tolerance:±4-5C

Application:Kitchen cabinet panel, elevator decoration, mechanical panel

Service:Free sample, One stop service

Packaging:Waterproof paper + wooden case

Process of Stainless Steel Mirror Polished Sheet

Surface Treatment

Firstly, the surface of the stainless steel plate needs to be treated to increase its adhesion. Chemical treatment agents or mechanical methods such as polishing, sandblasting, etc. can be used to wipe the surface clean and remove any dirt or oxide layer.

Primer

Next, apply a layer of primer. Primer can provide adhesion and good surface smoothness, ensuring that the imitation copper layer can firmly adhere to the stainless steel plate. Commonly used primers include polyester or epoxy resin coatings.

Imitation Copper Coating

After the primer has dried, apply a copper like layer. Imitation copper layer is a special coating that can simulate the appearance and texture of copper. This coating is usually made of resin containing copper powder or pigments. You can choose different copper like coatings to achieve the desired color tone and effect.

Glazing

After the imitation copper layer is dried, it can be polished to increase its luster. Transparent varnish or cleaning agent can be used for polishing to make the imitation copper layer look brighter.

Protective Treatment

Finally, in order to protect the imitation copper layer, a transparent protective coating can be used for treatment. This can prevent oxidation, fading, or other damage to the imitation copper layer, and extend its service life.

It should be noted that the stainless steel mirror surface is relatively smooth and easy to reflect light. When selecting and installing, it is necessary to consider the surrounding environment’s light conditions to avoid bright light from interfering with vision.

What We Offer

JYF Metal focuses on innovative stainless steel design, offering superior products and solutions with advanced technology, custom services and fast response.

One-stop Solution

JYF Metal provides a one-stop stainless steel project solution, as well as project design, advanced drawings , and installation instructions.

Excellent Graphic Representation

Skilled to use CAD, Solid-work, 3D-Max, Cored, help customers directly see the effect.

Installation Guide

We can provide professional installation guidance and suggestions for engineering projects to ensure the smooth progress of your engineering projects.

Combination of Product Beauty & Function

Strong ability of drawing analysis and deepening, ensuring the appearance design of your products, and at the same time ensuring the practicability of your products.

One-stop Solution

JYF Metal provides a one-stop stainless steel project solution, as well as project design, advanced drawings , and installation instructions.

Excellent Graphic Representation

Skilled to use CAD, Solid-work, 3D-Max, Cored, help customers directly see the effect.

Installation Guide

We can provide professional installation guidance and suggestions for engineering projects to ensure the smooth progress of your engineering projects.

Combination of Product Beauty & Function

Strong ability of drawing analysis and deepening, ensuring the appearance design of your products, and at the same time ensuring the practicability of your products.

Our Advantage

We have alwavs been commited to innovation and auality in decorative stainless steel finishes

Quality Assurance

Over ten years of product quality guarantee, provide timely and effective after-sales service.

Provide Free Samples

Free samples for metal color sheets and stainless steel decorative profiles to help you identify colors and models when making a bulk order.

Rich Experience

The engineer team has more than 15 years of experience and has undertaken a large number of engineering projects. Up to now, we have provided solutions for over 200 projects, including villas, Restaurant, Shopping Mall, high-end hotels and so on.

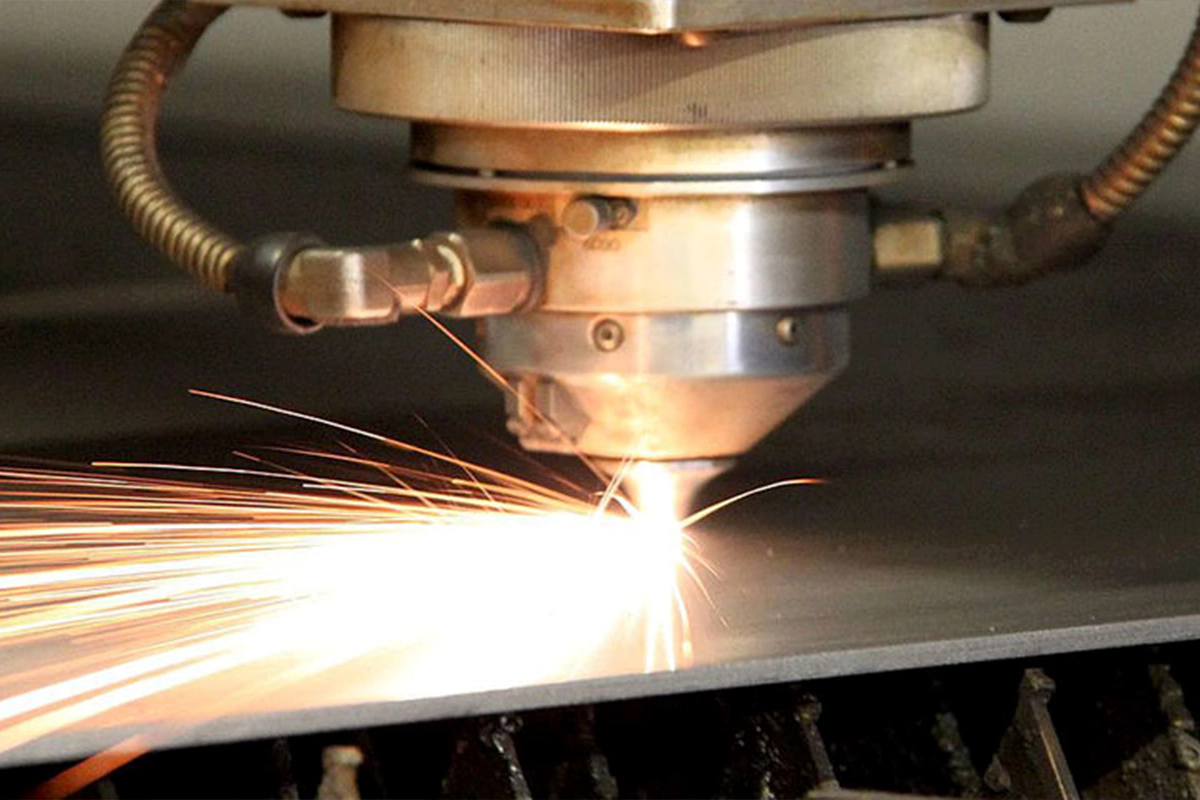

Advanced Equipment

We have much-advanced equipment such as TROMPF laser cutting equipment from Germany, CNC bending machine, roller equipment, vacuum PVD coating equipment, engraving machine, etching equipment, and so on.

Get A Inquiry !

JYF Metal has a solid technical team to provide you with suitable materials, surface treatment design, and installation guidance The JYF team will be at your service.

Application of Stainless Steel Mirror Polished Sheet

Stainless steel mirror panels are widely used. For example, building decoration, interior decoration, office decoration, elevator decoration, industrial decoration, image wall, commercial rear baffle, kitchen baffle, equipment decoration and other decoration, decoration, decoration and other fields.

Hotel lobby public area

Hotel lobby public area

Landscape design modeling

Landscape design modeling

In the visual effect of architectural design, the metallic mirror element is a required method, which uses cold metal to make the building talk with the space and reflects and mirrors the magical space effect, forming a personalized space experience. Designers often go out of their way to make mirror sheeting rich and unique. In the projects, the large area of mirrored stainless steel is used for both ceiling and wall. After the installation of all the space to form a reflection of the landscape, a fine mirror surface effect can an obvious visual impact. Stainless steel toughness and easy to shape, so designers have more imagination space to create.

Project Cases

To enhance the visual richness, the project designers will use attractive mirror elements in the space, such as 304 stainless steel mirror or mirror stainless steel products. The mirror finish is similar to the effect of the mirror, in highlighting the characteristics of the space and wall, with a metallic texture, but also easy to be overlooked space elements highlighted.

Factory Strength

Exhibition

Browse JYF Metal’s highlights at the international trade show. Here we assembled the exhibition of the wonderful moments and innovative products, to show our professional strength and design charm.

Frequently Asked Question

A1:Yes, stainless steel can be used as a mirror. It has a high level of reflectivity, especially when it is polished to a smooth and glossy surface. This makes it suitable for various applications where a mirror-like surface is ideal.

A2:① Clean the surface with a mixture of mild soap and water.

② Use a non-abrasive cleaner specifically designed for stainless steel surfaces.

③ Apply a small amount of metal polish to a soft cloth and gently rub the scratched area.

④ Purchase a stainless steel scratch remover from a hardware or home improvement store.

It’s important to note that the effectiveness of these methods depends on the depth and severity of the scratches. In some cases, deep or extensive scratches may require professional repair or polishing.

A3:The color of stainless steel mirror sheets is achieved through a process known as Physical Vapor Deposition (PVD) coating.

A4:Use warm water, a soft non-abrasive cloth or sponge, and a microfiber cloth for drying. Regular cleaning and maintenance will help keep your stainless steel mirror looking shiny and glossy.

A5:They can be used as decorative wall panels, wall cladding, elevator interiors, column covers, ceiling tiles, etc., to enhance the visual appeal of a space. They are also used in kitchen appliances, the automotive industry, signage, architectural displays, furniture decoration, and art sculptures.

A6:①When welding operations are carried out in the area where the mirror panels are installed, the surface of the panels should be effectively covered.

②During processing and installation, if the protective film falls off, it should be replaced promptly. A soft pad should be laid on the processing table to prevent scratching the mirror surface.

③When installing stainless steel 8K panels, the completed areas should be protected to prevent contamination and damage.

④Stainless steel 8K mirror sheets should only be installed after the completion of hidden items, such as pipeline installation, water testing, and insulation, and after all these have passed inspection.

⑤When installing decorative panels, workers should wear clean gloves to prevent contaminating the panel surface or injuring their hands with the panel edges.

A7:Stainless steel mirror polished sheets have extremely high durability and stability, making them suitable for structural framing and interior decoration. Additionally, cleaning stainless steel mirror panels is relatively simple.