Guide to Choosing a Suitable Stainless Steel Fabricator in China

Table of Contents

Understanding Your Requirements

Types of Stainless Steel Products

First of all, you need to determine what type of stainless steel product you require. Stainless steel is a versatile material that can be used in numerous applications, ranging from decorative and architectural to industrial and construction. Whether you’re looking for a custom stainless steel product, sculpture, tile trim, or screen partition, it’s essential to choose a fabricator with ample experience and knowledge to manufacture the specific product you need. Thus, understanding your requirements thoroughly is essential to finding an appropriate fabricator.

Different Processes for Different Products

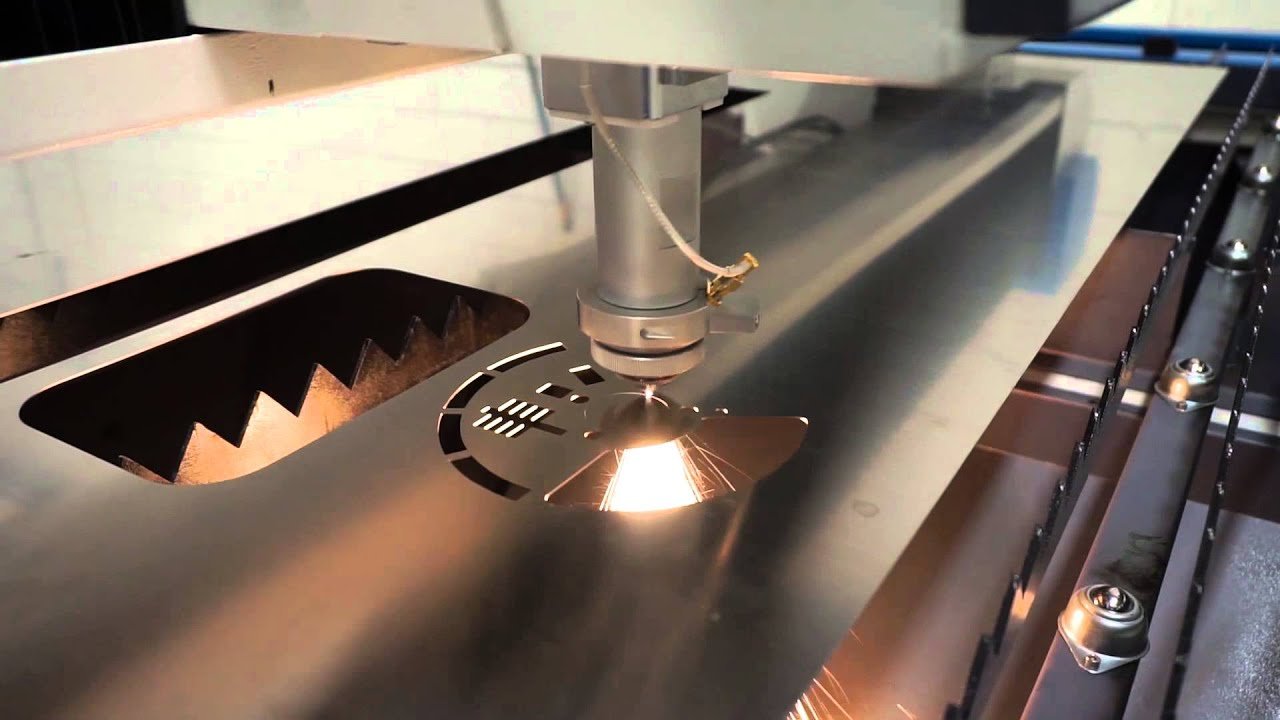

When identifying a fabricator, consider their processing capability. The processing method, equipment, tools, and skilled craftsmen necessary to produce stainless steel products vary depending on the application. For instance, fabricators that deal with sheet metal products, such as tile trims and decorative sheets, need equipment like bending, cutting, grooving, laser machines, welding, and polishing masters. Similarly, manufacturers that produce art ornaments and sculptures emphasize having a professional forging master.

Product Placement

The location where the product will be installed also significantly affects the materials used and the required specifications. For example, if you’re considering an outdoor or corrosive environment, a higher grade of stainless steel will be necessary to ensure durability and corrosion-resistant properties. Similarly, for indoor or outdoor decorations, different grades of Stainless steel hold up better in different environments. Stainless steel like SS201 offers excellent corrosion resistance and is suitable for indoor applications, while SS304 is well suited to food and beverage applications due to its high resistance to corrosion properties. On the other hand, SS316 boasts superior corrosion-resistant properties, making it ideal for outdoor placements in coastal and harsh environments.

Product Specifications

Product specifications are another important consideration. The product’s thickness, dimensions, tolerance levels, and other specific needs must be considered to deliver the required finish. For instance, profiles and designs that require a length of 6000mm need large processing equipment and ample space to place finished products. Surface finish is crucial as well; many products require specific surface finishes that suit the client’s preferences, environment and application.

Customization and Budget

Consider if you require customized products and clarify this with the fabricator. Customization requirements are also vital to consider when selecting a fabricator. Clients may have specific design and customization needs for their stainless steel products, such as size, finish, or design features. The fabricator should have the experience and knowledge to produce tailored products while still maintaining strict quality control. Also, different fabricators will have different pricing, so align this with your budget.

Quantity

It’s also important to consider the quantity of items you need. It affects lead times and pricing, so it’s crucial to figure out the requisite volume you require to procure things within your budget. Speaking of budgets, prices may vary from one fabricator to another, so be sure to stick with a fabricator that provides quality products within your budget.

Finding the Right Fabricator in China

By understanding your product needs, you can better choose Chinese stainless steel fabricators. I hope the following points can provide you with a better direction for thinking about your choice.

Expertise and Credibility

When on the hunt for a stainless steel fabricator, their level of expertise and credibility should be among your top considerations. Aim to collaborate with a firm that boasts a strong history of delivering top-notch stainless steel items. Opt for businesses with an established presence in the industry and a track record for dependable service. Prior to finalizing any arrangements, review their past work, customer feedback, and client endorsements.

Service Range

The process of fabricating stainless steel encompasses diverse techniques, such as cutting, bending, welding, and surface finishing. Inquire about the specific offerings provided by the fabricator to ensure they dovetail with the needs of your particular project. The ideal fabricator should possess the essential machinery, know-how, and manpower to successfully complete your venture.

Stringent Quality Measures

It is vital to scrutinize the quality assurance protocols followed by the fabricator. Confirm that they adhere to rigorous quality checks throughout the manufacturing stages. Look out for firms utilizing sophisticated test methods to validate that the end product aligns with your unique specifications. Moreover, they should have procedures to swiftly identify and rectify any quality issues.

Accreditations

The criteria for manufacturing can differ from one jurisdiction to another. To have confidence that your chosen fabricator maintains the utmost manufacturing standards, seek out relevant accreditations. Verify whether they hold qualifications such as ISO 9001:2015, awarded to companies meeting particular quality management criteria.

Client Interaction and Support

Transparent and efficient communication is vital when partnering with a stainless steel fabricator, particularly in China. Ascertain that the firm has established channels for clear client communication. A reputable fabricator will designate project coordinators to facilitate consistent updates throughout the lifecycle of the project. They should also be receptive to your input and aim to ensure the end product aligns with your expectations.

Pricing Considerations

Financial factors are another crucial aspect when selecting a stainless steel fabricator. Examine the cost structures of various businesses to identify one that offers premium services at a fair rate. While competitive pricing is tempting, it shouldn’t be the sole deciding factor. Evaluate other criteria outlined above before settling on a budget.

Export and Shipping Expertise

Confirm that the fabricator possesses the experience necessary for exporting products to your locale. Assess whether they work with domestic transportation agencies to enable smooth, punctual deliveries. They should be well-versed in export formalities and comply with the regulations pertinent to the country of destination.

Protection of Intellectual Assets

Safeguarding intellectual property is a key element to consider when outsourcing manufacturing endeavors to China. Opt for a fabricator committed to respecting your intellectual assets and conforming to established copyright and patent laws. Make sure they are willing to sign confidentiality agreements and other legal instruments to protect your designs and ideas.

Product Specifications

When seeking an apt stainless steel fabricator in China, it’s crucial to be explicit about your product needs. The fabricator should not only meet your specifications but also have the necessary skill set and capabilities. The more detailed and specific your requirements are, the more precisely the fabricator can offer an exact quote, lead times, and the most suitable manufacturing approach.

JYF METAL

JYF METAL stands as a comprehensive, all-in-one production and service enterprise, specialized in crafting customized metal products to meet the unique needs of engineering projects. Utilizing state-of-the-art production technologies along with a proficient research and development team, we are steadfast in our commitment to deliver a diverse range of decorative engineering solutions tailored to each client’s specific requirements.

Our portfolio encompasses a wide variety of offerings, ranging from metal decorative panels and architectural metal ceilings to intricate metal curtain walls and bespoke art pieces in metal. To ensure a seamless integration of our products into your projects, our highly skilled team offers personalized design consultations and production recommendations. These insights are geared towards meeting your project’s specific engineering requirements while also focusing on cost-efficiency and sustainability.

We take pride in our history of successful partnerships with globally acclaimed hotel chains, including but not limited to Hilton, Sheraton, and Westin. Beyond the hospitality industry, we have also collaborated with a diverse clientele of artists, architects, interior designers, and specialized engineering consultancies. This breadth of experience equips us with the versatility to tackle projects of varying complexity and scale.

Having established a commanding presence in the luxury stainless steel decorative panel sector, as well as the customized metal products market, JYF METAL has emerged as the service provider of choice for both domestic and international clients in need of customized decorative engineering solutions. Our adherence to high-quality standards, prompt delivery schedules, and customer-centric approach have cemented our reputation as leaders in the field.

We warmly welcome prospective and existing clients to visit our state-of-the-art factory. Witness firsthand the meticulous craftsmanship and advanced technology that go into creating each unique product. This transparent approach allows us to build stronger, trust-based relationships with our clients, further reinforcing our commitment to excellence and client satisfaction.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions