Does Stainless Steel Water Ripple Sheet Rust? Causes and Solutions Explained

Table of Contents

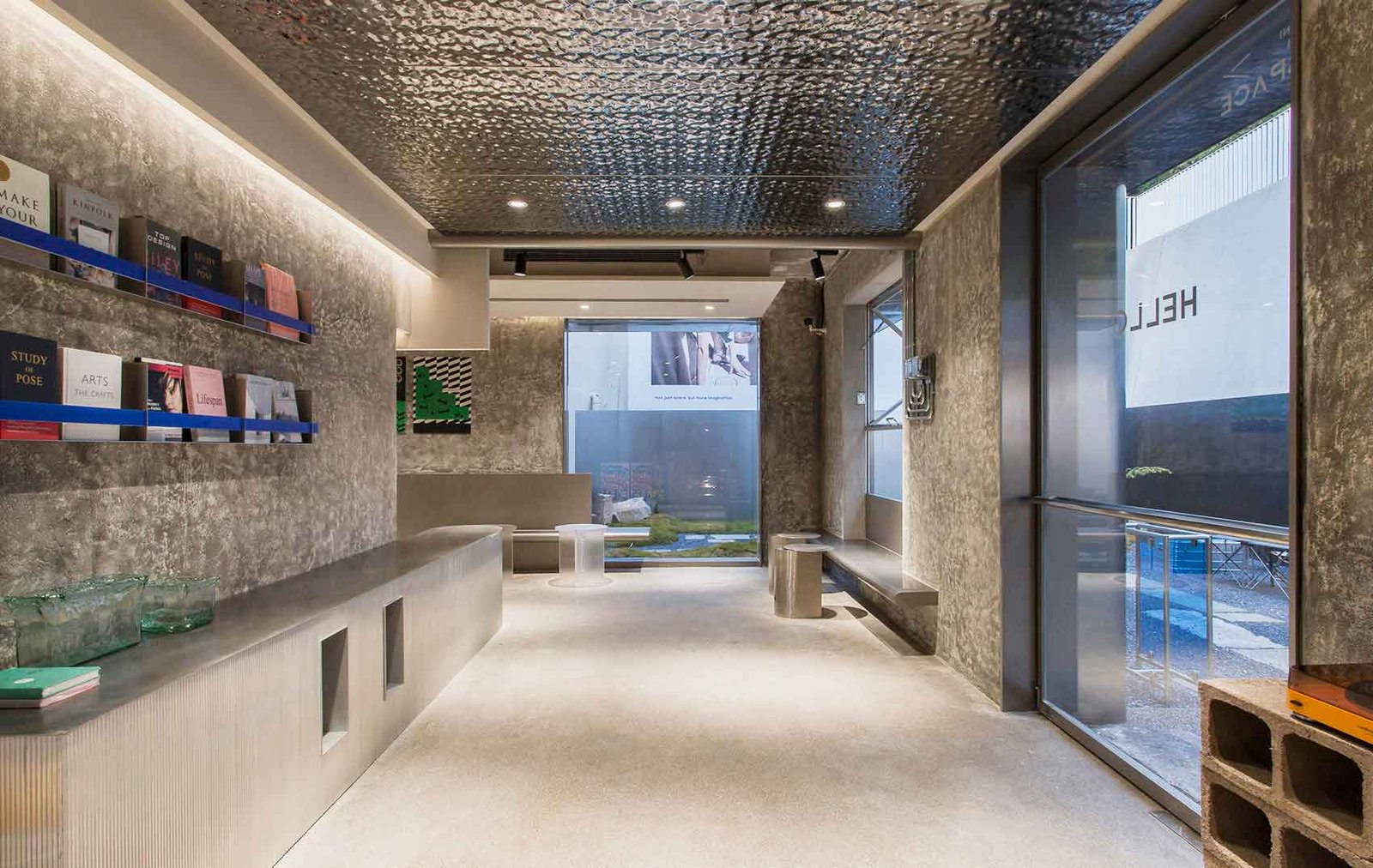

In architectural decoration and industrial applications, stainless steel water ripple sheets are highly favored for their distinctive texture and robust durability. However, some new customers have recently reported rusting on corrugated panels purchased from other sources, which is undoubtedly perplexing. Isn’t stainless steel renowned for its corrosion resistance? Why would it rust?

Today, let’s delve into the underlying causes of this phenomenon and provide comprehensive guidance for your selection and usage.

Analysis of Factors Contributing to Rust Formation on Stainless Steel Water Ripple Sheets

Material Considerations

Stainless steel comes in various grades, with common types including 201, 304, and 316. These grades differ significantly in composition and corrosion resistance.

- 201 Stainless Steel

Relatively inexpensive but with poor corrosion resistance. It contains less nickel, an element that enhances stainless steel’s corrosion resistance. 201 stainless steel is suitable for dry, non-corrosive environments such as interior decoration. It is prone to rusting when used in humid conditions or environments with corrosive gases.

- 304 Stainless Steel

This is the most common stainless steel grade, offering significantly better corrosion resistance than 201. It contains higher levels of nickel and chromium, with chromium forming a protective oxide layer that prevents rusting. 304 stainless steel is suitable for most indoor and outdoor applications, such as kitchens and bathrooms, though rusting may occur in extremely humid or salty environments.

- 316 Stainless Steel

This is the most corrosion-resistant stainless steel grade due to its molybdenum content, which further enhances corrosion resistance. 316 stainless steel is suitable for extreme environments like coastal areas or chemical plants. Even in these conditions, 316 stainless steel maintains its rust resistance for extended periods.

Surface Treatment Process Defects

Surface treatment is critical for stainless steel 3D water wave sheets. If not properly handled, the surface may develop scratches, pits, or uneven areas. While these minor issues may seem insignificant, they compromise the protective coating, allowing moisture and air to more easily reach the metal and cause rust.

e.g., if corrugated sheets skip acid pickling and passivation during production, their protective coating remains incomplete. This chemical treatment removes surface impurities and regenerates a uniform protective layer. Omitting this step significantly increases the sheet’s susceptibility to rust.

Impact of the Usage Environment

The usage environment significantly affects the corrosion resistance of stainless steel corrugated sheets. If installed in humid locations such as bathrooms, basements, or coastal areas, moisture in the air increases the risk of rusting. Additionally, environments containing corrosive gases like hydrogen sulfide or chlorine can accelerate rust formation.

Physical Damage

During installation and use, ripple sheets may sustain scratches, impacts, or dents. Such damage compromises the protective surface layer, exposing iron elements directly to air. When encountering humid conditions, these iron elements react with oxygen and moisture to form rust.

Key Considerations When Purchasing Stainless Steel Water Ripple Sheets

Selecting a Reliable Supplier

Choosing a reputable supplier is crucial. A good supplier provides quality assurance, ensuring the ceiling decorative stainless steel water ripple panels meet material standards and feature superior surface treatment. Assess reliability by reviewing supplier certifications, client feedback, and conducting on-site inspections of production facilities.

Price Comparison

Avoid being lured by low prices. Prices significantly below the normal range often indicate issues. Materials may be of poor quality or pre-damaged, with the corrugation process merely masking the defects. Some products may use materials that do not match the specified grade or steel type.

Focus on Material and Specifications

When procuring, clearly specify the required corrugated sheet material in the contract. For applications in humid environments or areas with corrosive gases, 316 stainless steel is recommended. For standard indoor use, 304 stainless steel suffices. Additionally, determine the sheet specifications – including thickness and dimensions – based on actual usage requirements.

Inspect Surface Quality

When procuring, clearly specify the required corrugated sheet material in the contract. For applications in humid environments or areas with corrosive gases, 316 stainless steel is recommended. For standard indoor use, 304 stainless steel suffices. Additionally, determine the sheet specifications – including thickness and dimensions – based on actual usage requirements.

Understand After-Sales Service

It is also crucial to understand the after-sales service provided by the supplier. A reputable supplier will offer quality guarantees and return/exchange policies. Should issues arise during use, you should be able to promptly contact the supplier’s technical personnel for assistance.

Maintenance Methods for Stainless Steel Water Ripple Sheets

Daily Cleaning

Regular cleaning is essential for maintaining the aesthetic appeal and extending the service life of stainless steel water ripple panels. For daily cleaning, use a soft cloth or sponge with a neutral detergent to wipe the surface. Avoid using cleaners containing acidic or alkaline corrosive ingredients, as these can damage the chromium oxide layer on the stainless steel surface, leading to rust. First, dampen the cloth or sponge with clean water, wring it out thoroughly, then apply a moderate amount of neutral detergent. Gently wipe the surface of the water-rippled panel to remove dust, grime, and fingerprints.

During cleaning, ensure wiping motions follow the direction of the rippled texture to prevent surface scratches. After cleaning, wipe away any residual cleaner with a clean, damp cloth. Finally, dry the surface thoroughly with a dry cloth to ensure no water spots remain. For stubborn stains that are difficult to remove, a specialized stainless steel cleaner may be used. However, always test the cleaner on an inconspicuous area of the water-rippled panel first to ensure it does not damage the surface.

Regular Inspection and Maintenance

In addition to daily cleaning, wall cladding water ripple stainless steel sheets should undergo periodic comprehensive inspection and maintenance. Focus on checking for surface damage such as scratches, dents, cracks, and signs of rust. If minor scratches or damage are detected, prompt repair is essential. For superficial scratches, specialized stainless steel scratch repair agents can be applied. The repair agent fills the scratches and forms a protective layer to prevent further rusting at the affected areas.

If rust appears on the surface of the corrugated sheet, immediate action should be taken. For mild rust, gently sand the affected area with fine-grit sandpaper to remove rust stains. Clean the surface with stainless steel cleaner, then dry thoroughly with a clean cloth. Apply a layer of stainless steel protective oil to restore surface luster and enhance corrosion resistance. For severe rust, professional rust removal equipment and techniques—such as sandblasting—may be required. However, ensure appropriate methods are selected to avoid causing secondary damage to the corrugated sheet surface.

Environmental Control

Controlling humidity and air quality in the usage environment is also a crucial measure for maintaining custom design 3D ripple stainless steel panels. In high-humidity environments, dehumidification equipment such as dehumidifiers can be used to maintain indoor humidity within an appropriate range, reducing the chance of water vapor condensing on the panel surface. Simultaneously, ensure adequate air circulation to prevent harmful gases and dust in the air from accumulating on the panel surface over extended periods.

For outdoor installations, consider adding protective covers or awnings to minimize surface erosion from direct sunlight and rain exposure. Furthermore, regularly clean debris and dust around the black PVD coated ripple stainless steel panels to prevent prolonged accumulation that could form corrosive agents.

Conclusion

Rusting issues with mirror water ripple stainless steel plates have long been a major challenge for many users. Through this comprehensive analysis, we understand that rusting primarily stems from the combined effects of material composition, surface treatment processes, usage environments, and physical damage.

During procurement, users must be vigilant, selecting reputable suppliers while meticulously verifying the material composition, specifications, and surface quality of corrugated sheets. Thoroughly understanding after-sales service is also essential. In daily use, regular cleaning, meticulous inspection, proper maintenance, and controlled environmental conditions are crucial preventive measures against rust. Only by seamlessly integrating these steps can the service life of Stainless steel water ripple wall cladding be effectively extended, ensuring they maintain their lustrous appearance and add unique charm to living and working spaces.

Selecting high-quality PVD coated ripple stainless steel panels and adhering to proper maintenance practices are essential to avoiding rust issues. As a renowned brand in the industry, JYF METAL remains committed to providing customers with premium products and professional services, ensuring every sheet maintains optimal performance across diverse usage environments.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions