100% Stainless Steel ?

Table of Contents

There is no single grade of stainless steel that is 100% stainless or completely immune to corrosion. Stainless steel is an alloy of iron, carbon, and varying amounts of other elements like chromium, nickel, and molybdenum. The addition of these elements helps to enhance the corrosion resistance of the steel and improve its other properties.

However, even the most corrosion-resistant grades of stainless steel can still corrode and rust under certain conditions. The extent and severity of corrosion depend on factors such as the chemical environment, temperature, oxygen content, and the surface finish of the steel.

In general, the higher the alloy content of the stainless steel, the more resistant it is to corrosion and the longer it will retain its attractive appearance. Grades 304 and 316 are among the most commonly used grades of stainless steel due to their excellent corrosion resistance properties.Therefore, while there may be grades of stainless steel that are more resistant to corrosion than others, there is no single grade that is absolutely 100% stainless or immune to corrosion. Proper selection, handling, and maintenance of stainless steel materials are essential to ensure their long-term performance and durability.

How to Identify the Stainless Steel

Identifying the type of stainless steel material can be essential in many applications. So how to identify stainless steel? The following are some ways:

Magnetic Test

One of the easiest ways to identify stainless steel materials is to use a magnetic test. Stainless steel materials are generally non-magnetic, except for certain types such as ferritic, martensitic, and duplex grades. If a piece of stainless steel is attracted to a magnet, it might indicate that it is not a pure austenitic grade. However, this is not always a reliable method since cold-working or welding can cause 201# stainless steel to become slightly magnetic.

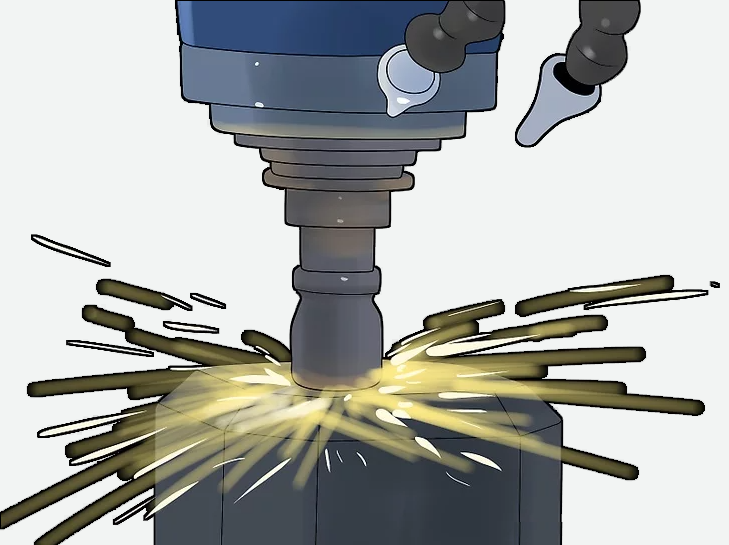

Spark Testing

Spark testing is a commonly used method to identify the type of steel material. It involves grinding a sample of the material on a grinding wheel, which results in sparks that are distinctive to the material type. The spark pattern for stainless steel is characterized by short, straight, and white sparks. Stainless steel grade 201# produces sparks that are longer and have a tail, while grades 304# and 316# produce shorter and straighter sparks.

Chemical Tests

There are various chemical tests that can be used to identify the type of stainless steel material, for example, a copper sulfate test can be applied to identify austenitic stainless steel material. The test involves applying a solution of copper sulfate to the material, and if the material becomes slightly pink, it indicates that it is an austenitic grade.

Stainless steel grade 201# has a lower nickel content than grades 304# and 316#, and this can be detected using copper sulfate or nitric acid testing. For example, the copper sulfate test can be used to distinguish between stainless steel 201# and 304# since only the 304# sample will turn slightly pink after being exposed to the copper sulfate solution.

Visual Inspection

The surface finish patterns on stainless steel materials are often different between grades, and they can be used to distinguish between different stainless steel types. For example, a bright, mirror-like finish may suggest that the stainless steel is a type 304 or 316, while a dull, brushed finish may suggest it is a type 201.

Spectrometry

In many cases, a spectrometry test can be used to identify the precise chemical composition of a stainless steel material. This method involves zapping a sample with an X-ray source and analyzing the resulting wavelengths that are emitted. The wavelengths indicate the presence of specific elements, which can be used to identify the material type. Therefore, this is the most accurate detection method.

In Conclusion

Identifying stainless steel materials can be done using a variety of methods, including magnetic tests, spark testing, chemical tests, visual inspection, and spectrometry. Each method has its advantages and limitations, and selecting the most appropriate method depends on the particular situation.

You Might Also Like

Please Share This

Recent Posts

- Custom Metal Fabrication for Hospitality Projects

- Decorative Stainless Steel Elements in Hospitality Architecture

- Stainless Steel Applications in High-End Residential Apartments

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Metal Sculpting and Structural Stability: Exploring Stainless Steel Designs

Vivian Huang

" Years of experience have taught me that professionalism and attention to detail are the keys to earning a client's trust. "

Email: vivian@jyfmetal.com