Why Stainless Steel U-Channels Are the Backbone of Your Next Project

Table of Contents

Every building or construction plan and design requires hard and stable materials. Whether you are constructing a home, designing an office space, or erecting a higher (raw) commercial structure, you will have to use the appropriate materials to do the job and determine the longevity, strength, and aesthetics of your structure. Bear in mind that the stainless steel U-channel is one element that is used in most projects.

This metal profile is widely applied in supporting, framing, and, in most cases, as an integrated functional and ornamental part. Serrated aluminum channel is U-shaped for mounting glass walls, sheltering edges, and increasing structural integrity. But what exactly makes it much better to use stainless steel? How does this compare to other materials? And how do you select the right stainless steel U-channel distributors?

In this article, I will answer these questions and explain why this essential component should be incorporated into the project.

What Is a Stainless Steel U-Channel ?

A stainless steel U section is a metal profile with a U-shape similar to the letter “U.” It has a broad base and two standing edges, or flanges, which enable it to be rigid. This makes it suitable for use as a structural beam, decorative beam, or in any other structure as a beam.

How It's Made

A stainless steel U-channel is manufactured through several processes, depending on the dimension and finish of the product:

Hot rolling involves rolling stainless steel and forming a U-channel form. This method is mainly utilized for large operational structures that need strong and robust supporting structures.

Cold Rolling: Stainless steel is a kind of material formed through shaping at or near room temperature and the process leads to a smooth surface and closer tolerances. Cold rolled U section stainless steel is widely used especially in the construction of building and structures where a smooth environment surface is required.

Laser Cutting & Bending: When it comes to cutting metal to complex shapes and sizes, laser cutting and bending is rich in clean cuts to the edges without any rough edges.And the use of stainless steel color plate to shear planing groove and bending, this processing mode is the most commonly used, the most rapid, and the finished product is the best effect!

Welding and/or Polishing: Some of these U-channels have other welding or polishing processes to improve their sturdiness and appeal. This is the processing method for stainless steel U shaped trim with special shapes or designs, or thicker material requirements. Often the shape is made and then surface treated.

Such production techniques make the stainless steel U-channel strong, smooth, and have a feature of being rust-free. But why should you consider stainless steel as the best option among all other materials ?

Why Choose Stainless Steel for Your U-Channels ?

Corrosion Resistance

As compared to ordinary steel, which forms rust over time, the stainless steel comprises chromium that does not allow moisture and chemicals to penetrate through it. This makes a stainless steel U section particularly suitable for the areas, which have a high level of humidity like the wash and the kitchen rooms and open territory.

Strength Without Too Much Weight

A U-shaped stainless steel channel is relatively light and, therefore, easy and safe to work with, and it also has the capacity to hold strong weight. This is even true in the current interior design, where some furniture needs to be strong and have a nice touch.

Low Maintenance

A polished stainless steel U-channel is also very easy to maintain after it has been fitted into place. Unlike painted or coated media, stainless steel does not require repainting after some time of use as it lacks the rough surface of these other types of media and hence does not tarnish easily. With a piece of cloth and some water, it goes on for years without any sign of getting degraded.

Modern Appearance

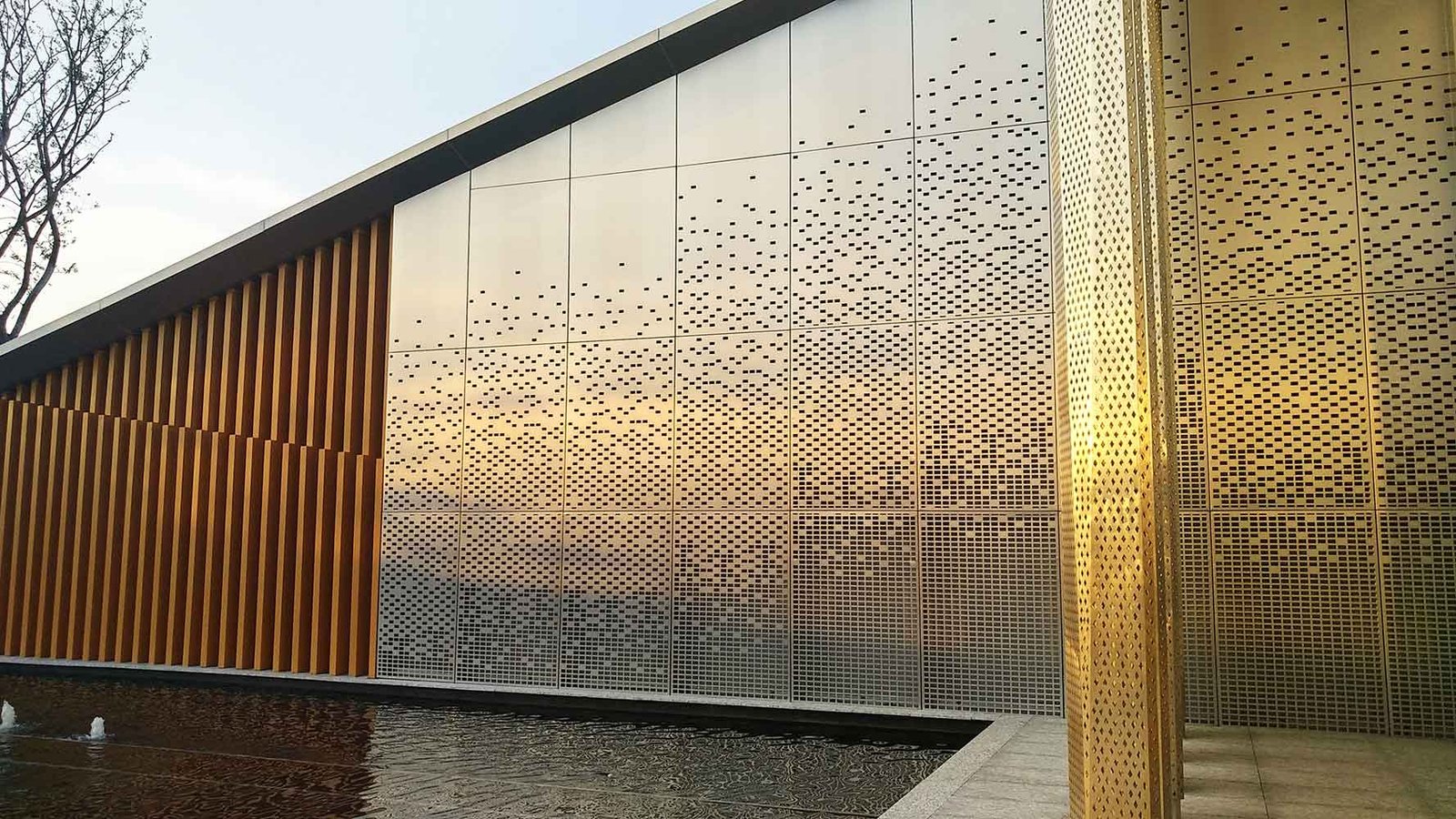

In terms of appearance, stainless steel is one of the top materials since it makes any appearance very attractive. It is an intrinsic part of the lean and modern look that one can get from large reflective buildings. A stylish U-shape made from stainless steel is applied to homes, offices, and other kinds of commercial buildings.

Long-Term Cost Savings

Nevertheless, stainless steel is relatively expensive compared to other types of materials for construction; however, it proves to be cheaper in the long run. As it is non-hastening to rust or damage, there are no frequent costs for repairs or replacements. This makes payment very attractive for investment, especially in small and big projects.

Now it is clear why stainless steel is the best material, let’s look through the application of stainless steel in interior and architectural projects.

Interior & Architectural Applications

A stainless steel U-shaped trim is among the modern building structures installed for functional and aesthetic purposes. There are several interior design and architectural applications that it is applied as follows:

Framing for Glass Partitions and Windows

Framing for glass partitions and windows are employed in buildings that require light weight construction and classy looks the frames for such partitions and windows are made with metals such as aluminum or steel, or can be made with laminated timber for aesthetic purposes due to their elegant looks.

In homes and offices, glass partitions offer light, a view, and a transparent environment. To support the glass, stainless steel U-channels are used, giving it a professional appearance. This also guarantees the safety of the glass throughout without having to use excessive framing.

Edge Protection and Trim

It is usually fixed on the walls, countertops, and furniture; it is made of polished stainless steel in the form of a U channel. This protects it from damage while giving it a fashionable, contemporary feel. The use of stainless steel trim is evident in areas such as shopping malls, hotels, and airports.

Staircases and Handrails

Typically, for the columns, down the stairs, and railing, a stainless U-channel is used because of its strength and appearance. Moreover, it supports the structure and coordinates well with windows as well as doors made from glass, wood, and stones. There are moments when the U-section stainless steel handrails are quite popular among architects and designers since they are aesthetically pleasing and very resistant.

Shelving and Support Structures

This application mainly uses the U-section stainless steel profile, which is found in retail shops, kitchens, and industries. The particular workhorse of the steel shelving systems is strong, highly durable, easy to clean, and fairly well resistant to moisture, and this makes them particularly suitable for use in commercial kitchens, laboratories, and stores.

U-channels are employed in many projects, and this makes it necessary to have a quality product supplier.

How to Choose the Right Stainless Steel U Channel Supplier ?

Different stainless steel U channel suppliers maintain different standards of quality. The following tips will help in selecting the right supplier:

High-Quality Materials

A good supplier is one that offers the product in 304 or 316 stainless steel, this metal is strong and cannot be affected by rust. These grades of stainless steel are very popular in today’s buildings’ construction and industrial purposes.

Customization Options

The thickness of the projects differs with different sizes and finishing. The best suppliers also supply polished steel U channel and steel fabrication, which can be ordered to one’s specifications. A supplier that offers services such as cutting and bending services guarantees the product offers the required dimensions.

Precision Manufacturing

For the purpose of employing sophisticated cutting and forming techniques, such as laser cutting and cold rolling, the supplier should consider the following factors. Such measures ensure that every single U-section stainless steel part is of high quality.

Reliable Supply Chain

It is vital to identify project due dates. Timely delivery is a key aspect when completing a project. There are certain aspects that are must-haves for any supplier that will be relied upon for large quantities of orders and shipments. As much as you may require only one piece of stainless steel U-channel or multiple sets of such a product, the supplier should guarantee the issuance of the material at the right time.

A good number of stainless steel U channel suppliers exist with desired functionality and design. Nevertheless, what is much more intriguing is how stainless steel stands in terms of comparison to other materials.

Stainless Steel vs. Other Materials

There are a number of varieties of U-channels, and for some reason, stainless steel stands out as preferable.

Stainless Steel

Material

Strength

Corrosion Resistance

Weight

Cost

Strength

High

Excellent

Moderate

Higher upfront

Low

Aluminum

Moderate

Good

Lightweight

Lower

Medium

Mild Steel

Very High

Poor (needs coating)

Heavy

Lower

High

Galvanized Steel

High

Moderate

Heavy

Medium

Medium

While aluminum is less dense than steel and cheaper yet less durable, the U-shaped channel made from stainless steel is the most preferable anodized material since it is strong, is not corroded by rust, and comes as the desired outlook.

Why Choose JYF Metal for Your Stainless Steel U-Channels ?

At JYF Metal, we not only offer stainless steel U-channel but are also a company that specializes in metal fabrications and has vast experience in cutting and metal subdivisions. We offer Quality, customization, and reliability as the right solutions provider for your project. These are the reasons why customers are confident to approach us for their needs in stainless steel U sections:

Custom Fabrication for Your Exact Needs

Unlike most of our competitors that only deal with standard sizes of equipment, we are able to fabricate any size of metal. Whether you require a particular shape, size, and length of U-section stainless steel profile, a polished stainless steel ‘U’ channel, or a structure for an architectural design, we can manufacture that particular product for you.

Premium-Grade Stainless Steel

These wires and cylinders are made from 304 and 316 standard stainless steel – both that provides proper resistance towards corrosion, strength and durability. This ensures that your U shaped stainless steel channel will withstand times even in the severe conditions.

Advanced Manufacturing for Precision and Efficiency

When it comes to the creation of the stainless U-channels we employ laser cutting, CNC machining, cold rolling as well as bending to ensure the highest accuracy of the measurements and the smoothness of the surfaces.

Bulk Orders with Fast Delivery

The manufacturing lines are able to accommodate voluminous order demands and they do not take a long time to attend to these orders. In terms of supply chain, the company is committed to a timely delivery of products for the local and international clients.

Competitive Pricing & Expert Support

Another one is that, being a direct metal fabricator, we do not incur higher expenses while offering high quality services. Our team has the most adequate knowledge to guide you on the most suitable stainless steel U section appropriate for the venture.

Conclusion

A stainless steel U-channel is an essential profile commonly used in construction and interior design. It is strong, corrosion-resistant, and looks modern; it is widely used in glass framework, edge protection, shelves, and staircases.

Use of a high quality stainless steel U section means that your project will not need to be renewed frequently because it will have a long life expectancy. For any style-related or structural application of steel U-channel or U-section stainless steel profile, nothing can be a wiser investment than the choice of stainless steel that is more durable than other materials.

Are you in search of accurate stainless steel U channels manufactured to your specifications? Do not hesitate to contact JYF Metal for a quote today.

FAQs

How can I request samples of stainless steel U shaped trim ?

We provide samples to help you evaluate the surface finish and reflectivity. Sample sizes are typically 200mm in length*or 300mm in length.

What finishes are available ?

We offer a variety of finishes, including mirror polish, brushed, matte. Additionally, PVD coatings are available in colors such as gold, black, bronze, and sapphire blue.

What is the lead time for custom stainless steel U channel ?

Lead times vary depending on the complexity of the order, including size, thickness, finish, and quantity. Typically, custom orders take 15-20days for production and delivery. Contact us for a precise timeline based on your project requirements.

Is it possible to order in large quantities, and how quickly can the products be shipped ?

Yes! We have several production lines to ensure that voluminous orders are managed effectively within the company. Our supply chain remains healthy, guaranteeing timely delivery regardless of the customer’s residence location.

Where can I get the right stainless steel U-channel for my project ?

There are various types of stainless U-channel suitable for your application, depending on the load and the environment in which it will be used. For inquiries on the most suitable U-shaped stainless steel channel, please contact us. We will be happy to advice, given your project requirements.

You Might Also Like

Please Share This

Recent Posts

- Custom Metal Fabrication for Hospitality Projects

- Decorative Stainless Steel Elements in Hospitality Architecture

- Stainless Steel Applications in High-End Residential Apartments

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Metal Sculpting and Structural Stability: Exploring Stainless Steel Designs