Top Stainless Steel Trims Everyone’s Choosing in 2026

Table of Contents

In modern architecture and interior design, meticulous attention to detail often determines the overall quality and style of a space. Stainless steel tile trims, with their unique luster, superior performance, and diverse shapes, have become a key element in enhancing the beauty and practicality of any space.

Whether used as decorative tile grout, wall moldings, corner protectors, ceiling edging, stair anti-slip strips, skirting boards, or even decorative furniture accessories, stainless steel decorative profiles, with their exquisite craftsmanship and diverse shapes, add sophistication and elegance to any space.

Stainless Steel Trims: Beauty of Details, Quality Choice

Applications

Stainless steel tile trim accessories are finely crafted from stainless steel. They are widely used on building exteriors, interior walls, ceilings, floors, and other surfaces, creating outlines, dividing spaces, creating decorative borders, and forming part of decorative patterns. Their durability and lustrous finish make them a standout among other decorative materials, making them an indispensable element in modern design.

Advantages

The material properties of custom stainless steel edge tile trim offer numerous advantages.

- Stainless steel possesses exceptional strength and toughness, capable of withstanding significant impact without deformation or damage. This makes it more stable and reliable, ensuring a long service life.

- Stainless steel’s surface undergoes special treatment, resulting in excellent corrosion and weather resistance, maintaining its original luster and performance in both humid indoor environments and outdoor weather.

- Stainless steel boasts a strong gloss, and various finishes, such as mirrored, brushed, and matte, can be applied to meet diverse design needs.

Installation

PVD coating stainless steel tile boards are relatively easy to install during the design and construction process. They can be attached to the substrate via welding, riveting, or specialized adhesives, ensuring efficient and precise installation. Furthermore, the size and shape of stainless steel decorative moldings can be customized to suit design requirements, seamlessly integrating into any space, from minimalist and modern to luxurious and classic.

Exquisite workmanship: Shearing, Folding and Grooving

Mirror finish stainless steel tile edge trims for wall corner protection of the production process is exquisite, which shear shaping is one of the core technology. This technological process not only embodies the advanced nature of modern industrial technology, but also embodies the wisdom and ingenuity of craftsmen.

Shearing

Shear process is the first step in the production of stainless steel metal tile edge profiles. Through the high-precision shearing equipment, the pvd colored stainless steel sheet is cut according to the design requirements. This process requires extremely high precision to ensure the smooth progress of the subsequent processing. The edge of the stainless steel plate after shearing is neat and smooth, which lays a foundation for the following bending and planing process.

For large thickness of the material, we will use laser cutting material shear.

Bending

Bending process is the key to shape U-profile stainless steel tile edging strips for ceramic wall tiles. With the help of professional bending equipment, mirror brushed stainless steel sheets can be folded into various complex shapes according to the requirements of design drawings, such as straight lines, curves, corners and so on. In the bending process, the bending angle and strength need to be precisely controlled to ensure the accurate shape of the line. After the bending treatment of stainless steel lines, has initially with the basic form of decorative lines.

Grooving

Grooving process is an important step in the fine machining of gold mirror stainless steel ceramic trims. With planing equipment, grooves can be cut into the back of the stainless steel plate to make the shape more straight and the bending angle more precise. And can remove the surface of stainless steel burrs, scratches and uneven parts, so that the lines of the surface more smooth and smooth.

Shearing, bending and grooving process is exquisite in its control of details and the pursuit of quality. Strict quality inspection is required at every step to ensure the dimensional accuracy, shape accuracy and surface quality of the final product. This process not only ensures the decorative trim strips of stainless steel beauty, but also gives its excellent practicality and durability.

Comparison of Materials :SS vs. AL vs. PVC

Decorative trims in the market, in addition to stainless steel trims, aluminum trims and PVC profiles are also more common. However, these three materials have their own advantages and disadvantages in terms of performance, appearance and application scenarios, and the choice needs to be balanced according to specific needs.

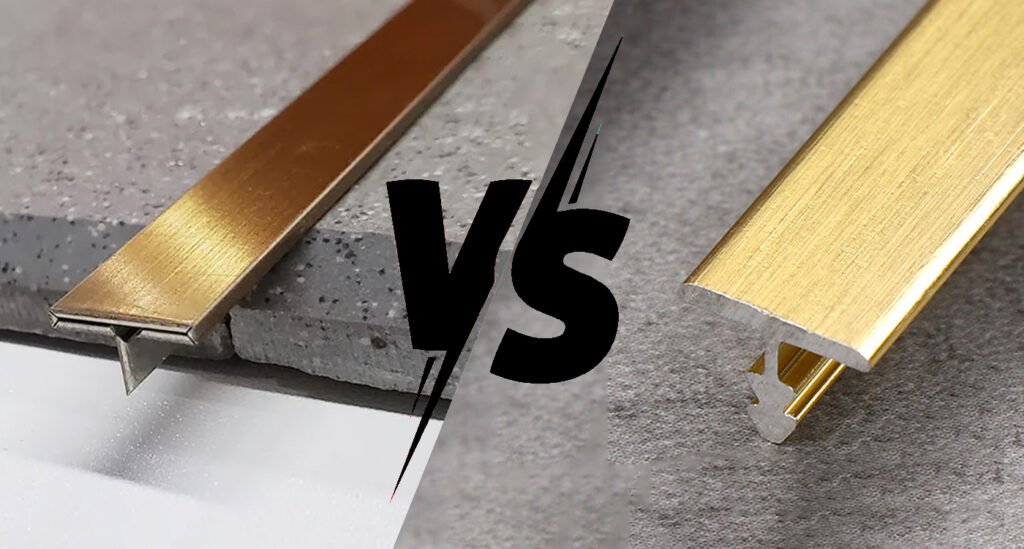

Stainless Steel vs. Aluminum

Strength and Toughness

Both stainless steel and aluminum are metallic materials with a certain degree of strength and luster, but they have significant differences in performance. The strength and toughness of stainless steel significantly better than aluminum, can withstand greater external impact and not easy to deformation or damage. This makes the stainless steel decorative profiles more advantageous in some scenes that require higher strength support, such as the decorative lines of the exterior wall of the building or the border decoration of the large interior space.

Corrosion Resistance

From the perspective of corrosion resistance, stainless steel after special treatment has good corrosion resistance and weatherability, can be used in a humid environment or outdoor environment for a long time without rust. Although aluminum also has certain corrosion resistance, but in some special environments (such as high salt spray environment) may appear corrosion phenomenon. Therefore, in the coastal areas or damp basement environment, 316L stainless steel decorative corner guard are more ideal choice.

Surface Texture

In terms of appearance, the luster of stainless steel is strong, and it can present a variety of effects such as mirror, drawing and frosting through different surface treatment processes to meet the needs of different styles of design. The luster of aluminum is relatively weak, and its appearance can only be improved by surface treatment such as anodizing. In addition, the texture of stainless steel is heavier and more solid, giving a sense of sedateness and atmosphere, while the texture of aluminum is relatively light, which is more suitable for some light and simple design styles.

Cost

From a cost standpoint, stainless steel is usually more expensive than aluminum. However, taking into account the long life of stainless steel, low maintenance costs, from a long-term use point of view, its cost-effective not inferior to aluminum. Especially in some of the decorative effect and high quality requirements of the project, the high value of stainless steel decorative lines can add color to the project.

Stainless steel vs. PVC

Strength and Toughness

First of all, PVC has much lower strength and toughness than stainless steel. It is easily deformed or damaged by external forces, so it is not suitable for some scenarios that require high strength support. For example, the decorative ceramic trims of building exterior walls or large interior space in the frame decoration, PVC profiles may be damaged by wind and rain or external collision, affecting the decorative effect and service life.

Corrosion Resistance

From the point of view of corrosion resistance, PVC has certain corrosion resistance, but its weather resistance is poor. In the long-term exposure to the outdoor environment, PVC vulnerable to ultraviolet irradiation and aging, fading, brittle, resulting in its decorative effect is greatly reduced. After special treatment, stainless steel can keep its original luster and performance for a long time, even in the harsh outdoor environment can also maintain good condition.

Surface Texture

In appearance, the texture of PVC is relatively poor, weak luster, can not be comparable with the metallic luster of stainless steel. Although PVC can be printed on the surface to simulate different textures and colors, but the overall effect is still a lack of stainless steel texture and sense of grade. In addition, the color stability of PVC is poor, which is easy to fade in the process of long-term use, while the color stability of stainless steel is high, which can maintain its original color for a long time.

Environmental Protection

From the perspective of environmental protection, PVC in the production and use process may release some harmful substances, the environment and human health caused by a certain impact. Stainless steel is a kind of environmentally friendly materials, its production and use process will not release harmful substances, more in line with the modern concept of environmental protection.

Conclusion

In the field of modern interior decoration, stainless steel decorative tile trims have become the key elements to improve the quality and aesthetic value of space with its excellent performance, exquisite technology and diverse modeling. Through a series of advanced processing technology, such as cutting and grooving, the stainless steel profiles are able to show incomparable fine and beautiful, whether it is the simplicity and fluency of straight lines or the elegance and flexibility of curves, can precisely fit the designer’s creative ideas for the space into a unique artistic charm.

In the balance of material selection, 304 stainless steel gold mirror edge strips compared to aluminum and PVC materials, showing a significant comprehensive advantage. Its high strength and high toughness gives the lines excellent durability, so that it can remain stable in the face of external impact and long-term use; Excellent corrosion resistance and weather resistance make the stainless steel line in the wet, changeable environment can also last as new, without too much maintenance, and rich surface treatment process, such as mirror, drawing, matte, etc. , it is to meet the needs of different styles of personalized space, from modern minimalist to luxury classical, can be perfect fit.

JYF METAL, as a leader in the field of stainless steel tile accessories in custom shapes, always uphold the ultimate pursuit of quality and continuous innovation of the process. Choose JYF METAL, you will receive not only high-quality products, but also professional, intimate service experience. We are committed to creating details for each project, lighting up your space with the exquisite beauty of stainless steel trims, achieving an extraordinary aesthetic model, so that your space always shines with unique light in the flow of time, highlight the extraordinary taste and style.

You Might Also Like

Please Share This

Recent Posts

- Custom Metal Fabrication for Hospitality Projects

- Decorative Stainless Steel Elements in Hospitality Architecture

- Stainless Steel Applications in High-End Residential Apartments

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Metal Sculpting and Structural Stability: Exploring Stainless Steel Designs