Stainless Steel Screens and Aluminum Carvings: A Blend of Art and Function

Table of Contents

In the realm of contemporary interior design, screens have consistently held a significant position as elements that blend practicality with ornamentation. When stainless steel screen frames are artfully combined with aluminum carving techniques, they not only offer designers a broader range of choices but also usher in an entirely new spatial aesthetic experience.

This decorative approach, blending tradition with modernity, sturdiness with lightness, and simplicity with luxury, is rapidly becoming a favorite in high-end interior design. This article will delve into the unique charm of combining stainless steel screens with aluminum carving, as well as its promising applications in contemporary spatial design.

Stainless Steel and Aluminum Carved Screen:

The Finishing Touch for Modern Spaces

Definition and Origin

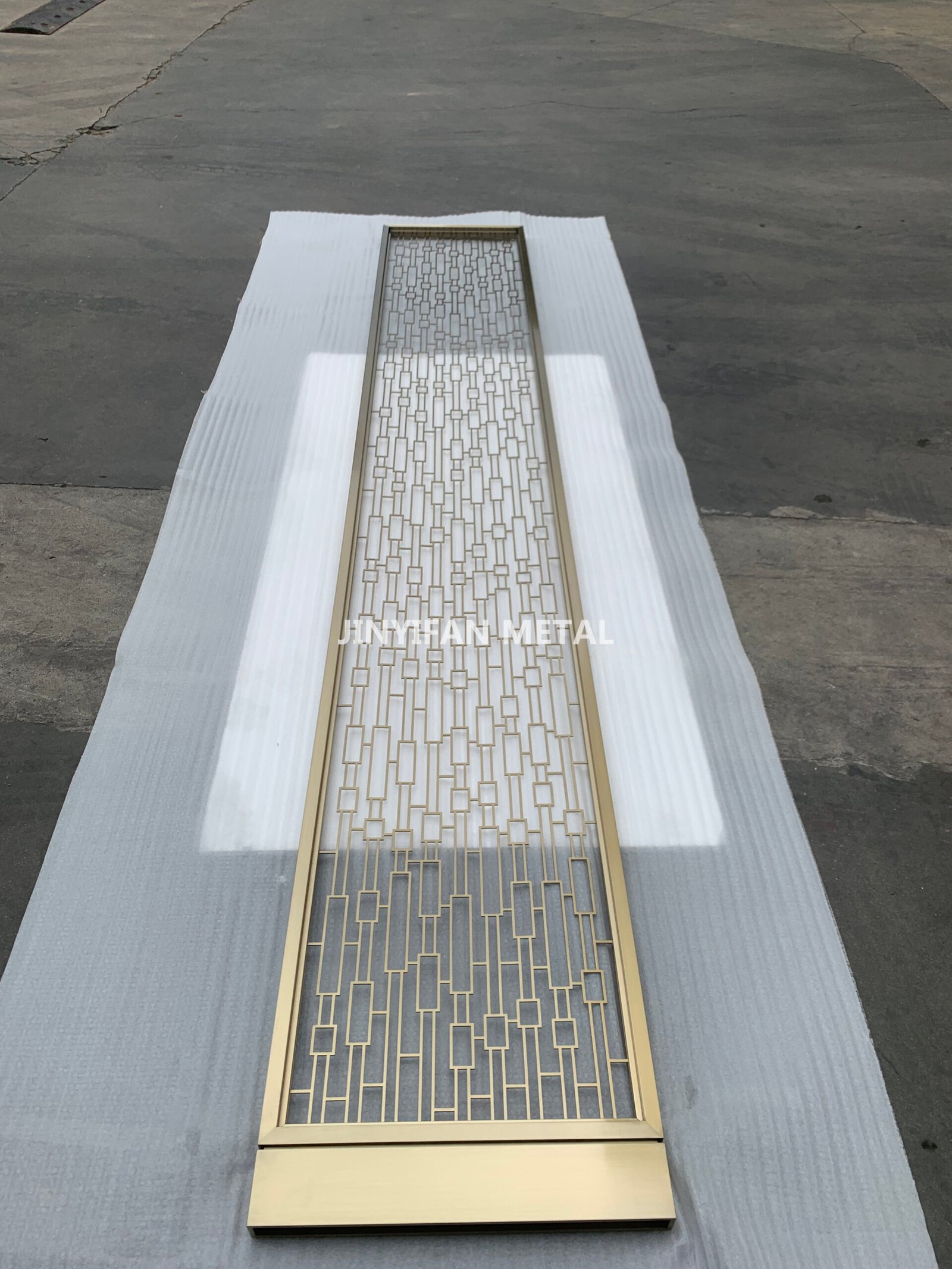

The stainless steel and aluminum carved screen is a decorative art piece that combines a stainless steel frame with aluminum carving techniques. It originated from a reinterpretation of the functionality and aesthetics of traditional screens. While traditional screens primarily used materials like wood and bamboo, advancements in modern technology have made stainless steel and aluminum ideal alternatives.

Stainless steel provides a sturdy, durable, and corrosion-resistant framework for the screen, while aluminum carvings add artistic flair with their intricate patterns and lightweight texture. This fusion not only preserves the traditional functions of space division and visual screening but also elevates the screen’s decorative and aesthetic appeal.

Design and Production

The design process for stainless steel aluminum-carved screens is a complex endeavor that integrates creativity and technical expertise.

- Designers first determine the overall form and dimensions of the screen based on the space’s style, functional requirements, and the client’s personalized specifications.

- Next, they select appropriate stainless steel materials and surface finishing techniques- such as polishing or brushing – to achieve the desired visual effect.

- For the aluminum carving elements, designers meticulously craft patterns- ranging from traditional motifs like floral arrangements, landscapes, and figures to contemporary geometric shapes and abstract designs. Advanced CNC engraving technology ensures precision and intricate detail in the carving process.

- Finally, the carved aluminum panels are assembled with stainless steel frames. After rigorous quality inspection, a stunning stainless steel aluminum carving screen is completed.

Application Scenarios

Stainless steel screen partitions with aluminum carving pattern offer extensive application possibilities.

- In hotel lobbies, they serve as reception backdrops or space dividers, creating a sophisticated and elegant ambiance. In restaurants, they delineate dining areas, enhancing privacy while maintaining an open feel.

- In offices, they serve as partitions that meet functional zoning needs while elevating the aesthetic appeal of the space.

- In residential settings, they can separate living rooms from dining areas or transition bedrooms into walk-in closets, infusing home spaces with artistic flair.

Whether in commercial or residential environments, stainless steel aluminum carved screens captivate with their unique charm, becoming standout focal points in any space.

Aluminum Carving Craftsmanship

Craft Process

Aluminum carving is a traditional sculpting technique that uses aluminum alloy as raw material. Through processes such as carving, openwork, and polishing, exquisite patterns and forms are created. The craft process primarily involves the following steps:

- Pattern Design

Designers create intricate patterns based on client requirements and spatial aesthetics. These designs may feature traditional Chinese motifs like dragons and phoenixes symbolizing prosperity, or plum blossoms, orchids, bamboo, and chrysanthemums, as well as modern geometric patterns or abstract artworks.

- Material Selection

Appropriate aluminum alloy materials are chosen. Aluminum alloy offers advantages such as lightweight, high strength, and strong corrosion resistance, making it highly suitable for carving.

- Carving

CNC engraving machines or manual carving tools are used to engrave the designed patterns onto aluminum plates. CNC machines ensure precision and consistency, while manual engraving better showcases the artisan’s skill and emotional expression.

- Polishing

After engraving, sand the aluminum plate to remove burrs and unevenness, achieving a smooth, refined surface.

- Surface Treatment

Apply surface treatments like painting, electroplating, or oxidation according to design requirements to enhance aesthetics and durability.

Artistic Value

Aluminum carving transcends mere decorative craftsmanship to become an art form. It seamlessly blends traditional sculpting techniques with contemporary design concepts, showcasing unique artistic charm through exquisite patterns and delicate lines. Aluminum carvings can be flat or three-dimensional, customizable to suit spatial requirements. In modern interior design, they are frequently employed as decorative elements such as accent walls, screens, and partitions, infusing indoor spaces with a rich artistic ambiance.

Integration with Stainless Steel Screens

When aluminum carvings are combined with stainless steel decorative screens, the two elements complement each other perfectly. The sturdiness and durability of stainless steel screens provide stable support for aluminum carvings, while the intricate patterns and lightweight texture of aluminum carvings enhance the artistic appeal of stainless steel custom partitions.

This combination not only elevates the visual impact of the screens but also amplifies their decorative and aesthetic value. In practical applications, designers can select appropriate aluminum carving patterns and stainless steel screen designs based on the style and functional requirements of the space, creating a truly unique spatial effect.

Comparison of Aluminum Carving and Stainless Steel Laser Screens

Material Comparison

Stainless steel laser screens typically utilize stainless steel material, employing laser cutting technology to create intricate patterns. Their advantages include high pattern precision, smooth lines, and the inherent durability and corrosion resistance of stainless steel. However, stainless steel laser screens are relatively heavy and may be slightly less effective in achieving complex patterns and layered effects.

In contrast, aluminum carved screens utilize aluminum alloy, offering benefits such as lightweight construction, high strength, and strong corrosion resistance. Aluminum carvings achieve greater complexity and dimensionality through multi-layer engraving and openwork techniques, delivering rich visual effects. These screens excel in spaces requiring a sense of lightness and transparency.

Craftsmanship Comparison

Stainless steel laser screens employ relatively straightforward manufacturing processes, primarily relying on laser cutting technology. While laser cutting enables rapid and precise execution of intricate patterns, the resulting designs often lack depth and dimensionality.

Aluminum carved screens involve more complex production steps, including design, carving, polishing, and surface treatment. Despite this complexity, the patterns achieved are more exquisite, with enhanced layering and 3D that deliver richer artistic expression

Cost Comparison

Stainless steel laser-cut screens have relatively lower costs, primarily influenced by stainless steel raw material prices and laser cutting processing fees. Their simpler manufacturing process and higher production efficiency grant them a competitive price advantage in the market.

Aluminum carved screens, however, carry higher costs primarily influenced by aluminum alloy raw material prices, engraving complexity, and labor expenses. The intricate production process and greater reliance on manual labor contribute to their elevated cost. Nevertheless, their high artistic value and distinctive visual appeal confer significant added value in the market.

Future Trends in Combining Stainless Steel Aluminum Carving Screen

Technological Innovation

With continuous technological advancement, the integration of stainless steel screens and aluminum sculptures will continually incorporate new techniques. For instance, 3D printing technology can be employed to create more intricate aluminum patterns, enhancing production efficiency and design precision. Intelligent control systems enable automatic opening, closing, and adjustment of screens, boosting their functionality. Furthermore, the development of novel materials will unlock additional possibilities for combining stainless steel screens with aluminum sculptures.

Design Innovation

In design, the integration of stainless steel screens and aluminum carvings will emphasize personalization and diversity. Designers will move beyond traditional patterns and forms, increasingly blending modern design concepts with traditional craftsmanship to create more innovative and artistic pieces. For instance, abstract art combined with traditional carving techniques can produce screens with a contemporary and futuristic aesthetic; integrating natural elements with geometric shapes can evoke a harmonious beauty that bridges nature and modernity.

Market Expansion

Driven by the pursuit of high-quality living and personalized spaces, the integration of stainless steel screens and aluminum carvings will find broader market applications. Beyond traditional commercial settings like hotels, restaurants, and offices, it will gradually enter residential spaces—including homes, villas, and apartments—emerging as a new choice for home decoration. Moreover, with the growth of the cultural tourism industry, this fusion will increasingly grace cultural venues like museums, art galleries, and theme parks, offering visitors distinctive cultural experiences.

Conclusion

The integration of stainless steel screens and aluminum carvings represents not only an innovation in materials and craftsmanship but also a revolution in spatial aesthetics. It seamlessly blends tradition with modernity, sturdiness with lightness, and simplicity with luxury, offering designers and clients more diverse choices.

In future interior design, this combination will continuously introduce new technologies, designs, and applications, showcasing even broader prospects.

As an innovator in this field, the JYF METAL remains committed to developing and producing high-quality stainless steel screens and aluminum sculptures. We deliver personalized, artistic spatial solutions that set new trends in interior decoration.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions