Reflective Artistry: The Captivating Use of Mirrored Panels in Architectural Design

Table of Contents

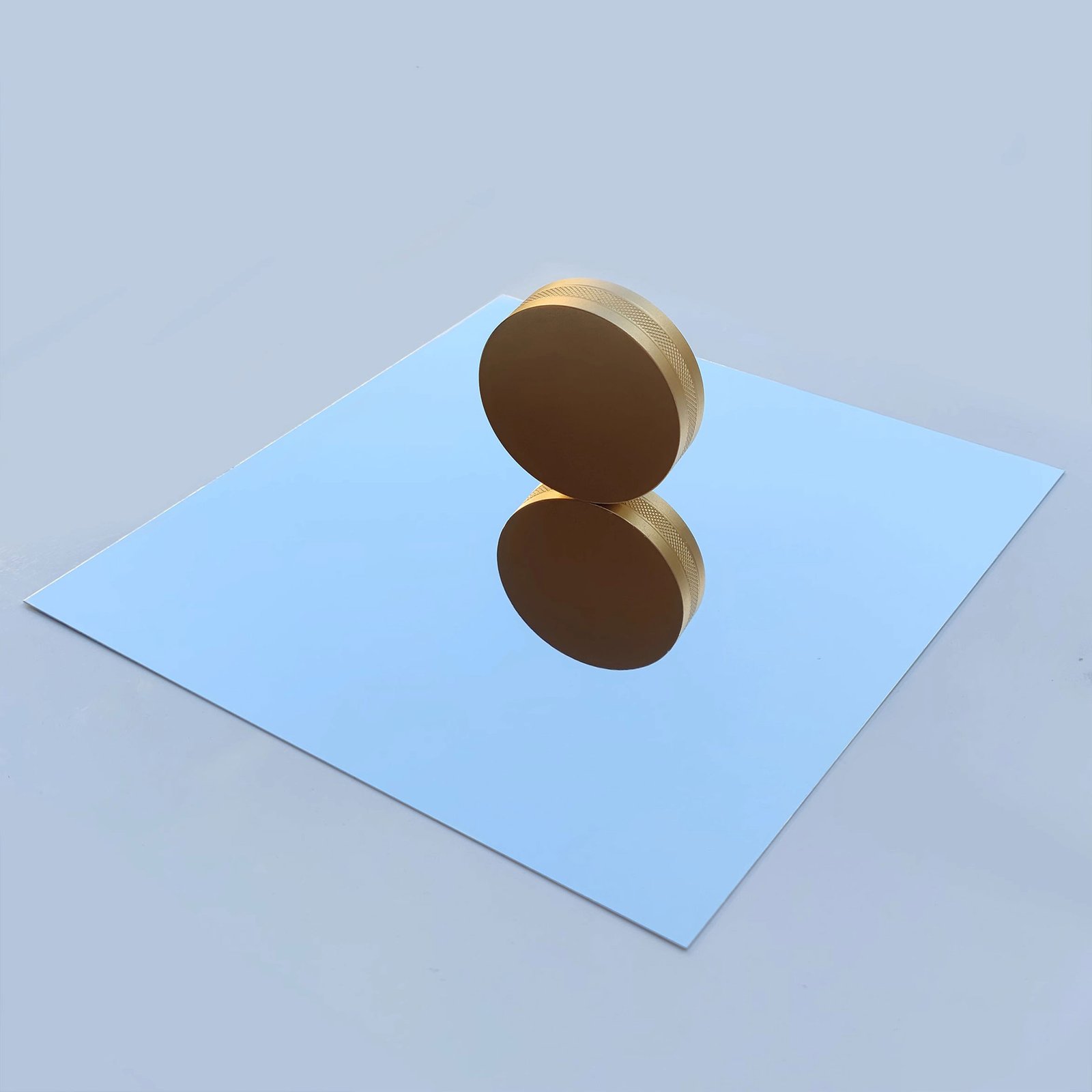

In contemporary architectural landscape visual design, the use of mirrored materials is an indispensable element. Employing unique materials facilitates a dialogue between the architecture and space, while reflections and mirrors give rise to enchanting spatial effects, creating a distinctive spatial experience. In the hands of designers, the manipulation of mirrored materials continues to evolve creatively. Today, we present several commonly used mirrored materials, hoping to provide valuable insights for you.

Mirror Stainless Steel

Stainless Steel Specifications

Mirror stainless steel involves using grinding fluid to polish the original material through polishing equipment on the surface of stainless steel sheets. This process achieves a smooth surface with clarity resembling a mirror. Mirror stainless steel is one of the most well-known types among mirrored materials. “Mirror” refers to the surface condition of stainless steel and is commonly used for thinner specifications in cold-rolled stainless steel sheets.

Stainless Steel Insights

Stainless steel, abbreviated as “SS,” is corrosion-resistant steel, resistant to weak corrosive media such as air, steam, and water. It possesses characteristics of heat resistance, corrosion resistance, and rust resistance, making it an excellent material for both outdoor and indoor use. The commonly used stainless steel includes 304, 304L, 316, and 316L.

Stainless steel is an alloy material, and 316 stainless steel adds molybdenum, which strengthens the molecular structure, enhancing wear resistance and oxidation resistance. 304L and 316L have lower carbon content compared to 304 and 316, as clearly outlined in the material content table. The rust resistance of stainless steel is primarily due to the chromium-rich oxide film formed on the surface. However, at high temperatures, intergranular corrosion may occur. Therefore, 304L and 316L have lower carbon content, reducing the risk of intergranular corrosion. In terms of corrosion resistance, 304 < 304L < 306 < 306L, with prices increasing accordingly.

From an application perspective, 304 stainless steel can meet the requirements of daily use in inland cities, while areas with higher air humidity and better light conditions, such as southern and coastal cities, may require stainless steel of 304L and above.

For decorative purposes, 201 # , 304 # , 316 are the most common.

Brightness of Mirror Stainless Steel

Common mirror stainless steel comes in four grades: 6K, 8K, 10K, and 12K. Generally, 8K mirror stainless steel achieves a smooth surface effect similar to an ordinary mirror. The 6K stainless steel has some brightness on the surface but cannot be considered mirror stainless steel.

The best effects are observed with 10K and 12K. 12K mirror stainless steel has an ultra-clear surface with no grinding marks or scratches, making it virtually flawless. However, the cost of polishing is higher, resulting in a relatively higher price.

Stainless steel is used for interior and exterior cladding of buildings. Apart from mirrors, other common surface treatment processes include brushing, sandblasting, pvd coating, etching, and anti-fingerprint (AFP).

Thickness of Mirror Stainless Steel

The thickness of 8K/12K mirror stainless steel panels can range from 0.3 to 100mm. Thicker panels, more surface defects, grinding to achieve a mirror effect is more challenging, the corresponding increase in processing costs.

Mirror stainless steel, being relatively thin, may undergo slight deformation in flat applications. It is suitable for curved surfaces, offering high stability and hardness. Compared to other mirrored materials, it has higher wear resistance and is easy to clean in daily use.

Applications of Mirrored Stainless Steel

The surface of mirror stainless steel can create reflections, projecting the surrounding scenery through mirrors in a ethereal manner, reflecting authentic content. In landscape design, incorporating mirror stainless steel can expand space, enhance focal points, and infuse a sense of technology and futurism.

However, improper usage can lead to negative effects such as light pollution, susceptibility to scratches, and compromised aesthetics. Vigilant post-installation maintenance is crucial. It’s important not to excessively use mirror stainless steel, as it may induce a sense of tension and negatively impact the overall spatial experience.

Water Ripple Stainless Steel

Water ripple stainless steel is a trendy design material created through stamping processes on mirror stainless steel in recent years.

During the rolling process, corrosive liquids are typically employed, resulting in varying depths of patterns on the plate. The color of the water ripple stainless steel plate, approximately 20-30 micrometers deep, can also be customized during production, creating a seamless integration of the main body with the coloring layer to preserve the fundamental structure and performance of the original stainless steel.

Mirror Aluminum

Mirror aluminum plate is a specialized aluminum veneer material that undergoes mirror treatment to achieve a reflective surface. The process for creating a mirror effect on the aluminum plate typically involves polishing, coating, rolling, and other methods. For high-end mirror aluminum plates, a secondary processing of surface oxidation is often applied.

There are various types of specular aluminum plates produced through different processes, ranging from low to high quality. These include film-sticking specular aluminum, domestically polished specular aluminum, imported polished specular aluminum, imported oxidized specular aluminum, and super-specular aluminum plates.

Mirror aluminum plates are commonly rolled abroad, resulting in both coil and sheet forms. The mirror aluminum rolled overseas tends to exhibit a superior mirror effect compared to domestic aluminum, with a higher price tag. The maintenance of the mirror effect is enhanced through surface oxidation in secondary processing. Without this secondary treatment, the mirror rate tends to decrease over time.

The term “mirror aluminum plate” is broad, and it can be categorized based on surface reflectivity into standard mirror, high mirror, and super mirror. High-end specular aluminum panels typically boast a reflectivity of 90%.

Insights into Aluminum Sheets

Aluminum sheets are broadly categorized into two main types: aluminum veneer and aluminum composite plates. Aluminum veneer involves utilizing an aluminum alloy plate as a base, undergoing processes such as chrome treatment, digital bending, and other molding technologies. It emerges as a novel architectural decoration material crafted through techniques like fluorocarbon or powder spraying.

On the other hand, aluminum composite plates serve as a general term encompassing the use of chemically treated coated aluminum plates (aluminum veneer) as a surface material, combined with a suitable base material to create a composite aluminum plate. Common examples include aluminum-plastic plates (plastic + aluminum veneer) and metal honeycomb aluminum plates (honeycomb metal + aluminum veneer). Each variant offers distinct characteristics, contributing to the versatility of aluminum sheets in architectural applications.

Acrylic Mirror Panels

Acrylic mirror panels stand as a superb alternative to traditional glass mirrors, primarily finding application in indoor environments due to the addition of a coating on the acrylic base.

Acrylic Mirror Material for Kitchen Door Panels

These versatile acrylic mirror materials can also serve as kitchen door panels. Utilizing 2mm or thicker acrylic mirror material for the doors can achieve a mirror reflection effect comparable to glass mirrors. This caters to the preferences of consumers who seek impactful imaging without pursuing extremes.

Acrylic Mirror Material for Closet Door Panels

The closet door panels crafted from acrylic mirrors offer a practical solution. For consumers favoring the mirror effect, acrylic mirror material can be employed as the front material for the door panel. Conversely, for those not keen on the mirror effect, using acrylic mirror material on the back of the door panel allows it to function as a mirror when opening the closet door. This dual functionality ensures flexibility in meeting diverse consumer preferences.

Applications of Mirror Panels

BURBERRY Pop-Up Store, Jeju Island, South Korea

Burberry recently erected a “Mirror Palace” in Jeju Island, South Korea. Named “Imagined Landscapes,” it’s a limited-time boutique experience store and Burberry’s first immersive brand experience gallery. The exterior is primarily composed of reflective mirror materials, blending natural landscapes and technological exploration to deliver a futuristic and visually stunning experience.

Reflektor Pavilion, France

Design: Atelier ARI

This pavilion showcases a solid and functional bowl-shaped structure, designed by architect and urban planner Winy Maas-led MVRDV team for Depot. The mirrored surface aims to create a building that blends into the urban environment, serving as a secure fortress for storing billions worth of art treasures.

Qixianxiafang Bridge City Library

Design: Yikao Architecture

Situated above large steps between the building and the square, this library features a large roof providing shade and shelter. The mirrored stainless steel ceiling reflects the activities below, akin to a recording device capturing the moments of Qixianxiafang Bridge City residents.

National Holocaust Names Monument, Netherlands

Design: Studio Libeskind

Positioned between the subway and the street, this monument consists of floating stainless steel blocks. The significance lies in light and reflection, contributing to people’s understanding of the Holocaust and the lives lost.

Imagination Pavilion, Seoul

Design: Unsangdong Architects

Transforming an old lookout tower into a leisure and entertainment facility, the Imagination Pavilion offers panoramic views of the city. With a structure supported by columns, stairs, and a mirrored stainless steel ceiling, it serves as a three-dimensional telescope, providing a new artistic and cultural entertainment space.

"Black Square," Moscow

Design: Gregory Orekhov

This surreal effect is achieved by installing full-length polished stainless steel mirrors on both halves of the cube. Such steel plates, not readily available in Russia, require meticulous craftsmanship in the artist’s studio. The application of this technique represents a return to nature, contrasting with historical processes and notions of progress.

Curved Mirrored – Facade Design, Sydney

Design: AR-MA

A project originating from a cloud survey of 3D architectural concrete, this design involves 152 unique stainless steel mirrored panels crafted using various manufacturing processes. Each panel is marked, tracked, and undergoes multiple layers of packaging before being assembled on-site.

Vienna Steirereck Restaurant

Design: PPAG architects

The restaurant’s exterior comprises large electric sliding windows and reflective mirror aluminum panels, providing excellent acoustic and thermal comfort. It creates an extraordinary yet inviting image, allowing diners to feel as if they are dining outdoors with a direct connection to the park.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions