PVD-Coated Stainless Steel Sheets: Durability Meets Elegance

Table of Contents

What is PVD Coating ?

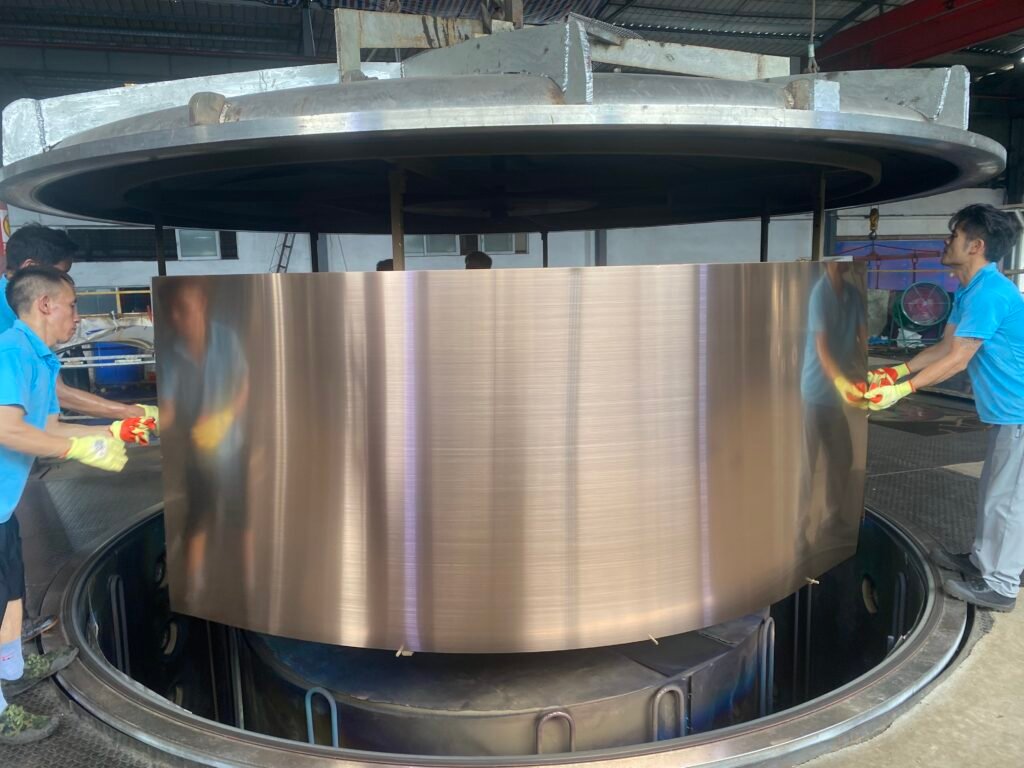

PVD (Physical Vapor Deposition) coating is a process that deposits a thin layer of a certain material onto a substrate through a vacuum chamber. PVD coating has become a popular surface treatment for stainless steel sheets as it offers an array of benefits.

Our PVD stainless steel sheets provide unmatched durability, corrosion resistance, and aesthetic appeal. With a solid-state vacuum deposition technology, these coatings offer a seamless layer of color and texture, making them a perfect fit for various design projects.

Our range of customizable colors and finishes ensures that you can achieve any design you desire while still enjoying the outstanding benefits of PVD coating. From automotive to architectural and kitchen equipment, our PVD-coated stainless steel sheets are an excellent choice for a long-lasting and sophisticated appearance.

In this article, we will discuss the advantages and disadvantages of PVD-coated stainless steel sheets and their applications.

Prons & Cons of PVD-Coated Stainless Steel Sheets

Pros

Corrosion-Resistance: Stainless steel is already highly corrosion-resistant, and the PVD process further improves this. PVD coatings are designed to enhance the substrate’s corrosion-resistance, making them an ideal choice for applications in harsh environments.

Aesthetic Appeal: PVD finish stainless steel sheets are available in a wide range of colors and finishes, such as shiny, matte, and textured. This allows for greater customization and gives designers more options when creating their vision.

Easy Maintenance: PVD coating stainless steel sheets are easy to maintain and clean. The coating’s non-porous surface means that dirt, grease, and other contaminants cannot adhere to it, allowing for easy cleaning with a soft cloth and mild detergent.

Environmental Benefits: PVD coating is an environmentally-friendly process as it does not involve the use of chemicals, and the coating materials are recyclable.

Cons

High Cost: PVD coating is a relatively expensive process compared to other coatings, which can make the overall cost of PVD-coated stainless steel sheets quite high. However, the durability and extended life of PVD coatings can make the investment worthwhile.

Limited Thickness: PVD coatings are relatively thin and may not be suitable for some applications requiring a thick coating.

Limited Repair Options: In the event of significant damage or wear, PVD coatings are difficult to repair. Complete removal and reapplication of the coating may be necessary, which can be costly and time-consuming.

Surface Damage: Although PVD coatings enhance the surface hardness of stainless steel, they can still be susceptible to damage from sharp objects or abrasive materials. Scratches or deep gouges on the coating can expose the underlying stainless steel, potentially compromising its aesthetic appeal.

Chemical Resistance: While stainless steel itself boasts excellent corrosion resistance, the PVD coating may not offer the same level of protection against certain chemicals or harsh cleaning agents. It is important to consult the manufacturer’s guidelines for proper maintenance and cleaning procedures to avoid potential damage to the coating.

Applications of PVD-Coated Stainless Steel Sheets

The benefits of PVD-coated stainless steel sheets make them ideal for a range of applications. Here are some examples:

Architecture

Stainless steel pvd sheets are commonly used in architectural applications, such as facades, canopies, and elevator interiors. The customizable color options and durability make it an excellent choice for these applications.

Medical Equipment

PVD coated stainless steel sheets can be used in the manufacture of medical equipment, including cabinets and work surfaces, as the coating's non-porous surface is easy to clean and maintain.

Automotive Industry

PVD-coated stainless steel sheets are used in the automotive industry for interior and exterior applications, such as trim and bodywork.

Kitchen Equipment

PVD ss sheet is ideal for use in kitchens, such as counter-tops and backsplashes, as the coating's non-porous surface is easy to clean and maintain.

Will Pvd-Coated Stainless Steel Sheets Fade ?

PVD-coated stainless steel sheets are highly resistant to fading due to the nature of the PVD coating process. The coating is created through a vacuum process that bonds the coating material with the stainless steel substrate, creating a strong and durable surface. The coating is highly resistant to wear and peeling, making it a popular choice for high-traffic areas in the architectural, automotive, and kitchen equipment industries. However, prolonged exposure to sunlight, harsh chemicals, and physical abrasion may affect the coating’s long-term durability and cause some fading over time. To maintain the color and integrity of the PVD coating, it is best to follow proper care and maintenance guidelines.

How to Maintain and Prevent Fading ?

To maintain the color and integrity of stainless steel pvd sheets and prevent fading, it is essential to follow proper care and maintenance guidelines. Here are some tips for maintaining the PVD coating:

Regular cleaning: Clean the PVD-coated stainless steel sheets regularly with a mild soap and water solution and a soft cloth to remove any dirt or debris that could damage the surface.

Avoid harsh chemicals: Do not use harsh chemicals, abrasive cleaners, or steel wool pads on the surface of the coating as it could damage the coating.

Avoid prolonged exposure to sunlight: Prolonged exposure to direct sunlight can cause fading and damage to the coating. Avoid exposing the surface to direct sunlight for extended periods.

Promptly remove stains: Stains or spills should be cleaned as soon as possible to avoid leaving marks or discoloration on the surface.

Consider the environment: The PVD coating is highly durable, but harsh environmental conditions may affect its long-term durability. If the stainless steel sheets are located in harsh environments with high levels of humidity or saltwater, it is essential to rinse the surface regularly with freshwater and clean the surface more frequently to avoid staining or corrosion.

By following these guidelines, you can maintain the color and integrity of the PVD coating on your stainless steel sheets and enjoy their high-quality appearance for years to come.

In Conclusion

PVD coating is an advanced surface treatment that offers several benefits for stainless steel sheets, including durability, corrosion-resistance, and customizable color options. Although it is a relatively expensive process, the extended durability and maintenance-free nature of the coating make it a valuable investment for many applications. PVD-coated stainless steel sheets are ideal for use in the automotive industry, architecture, medical equipment, and kitchen equipment, among others. With its many advantages, it is no surprise that PVD-coated stainless steel sheets have become a popular choice in the industry.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions