Perforated Plate

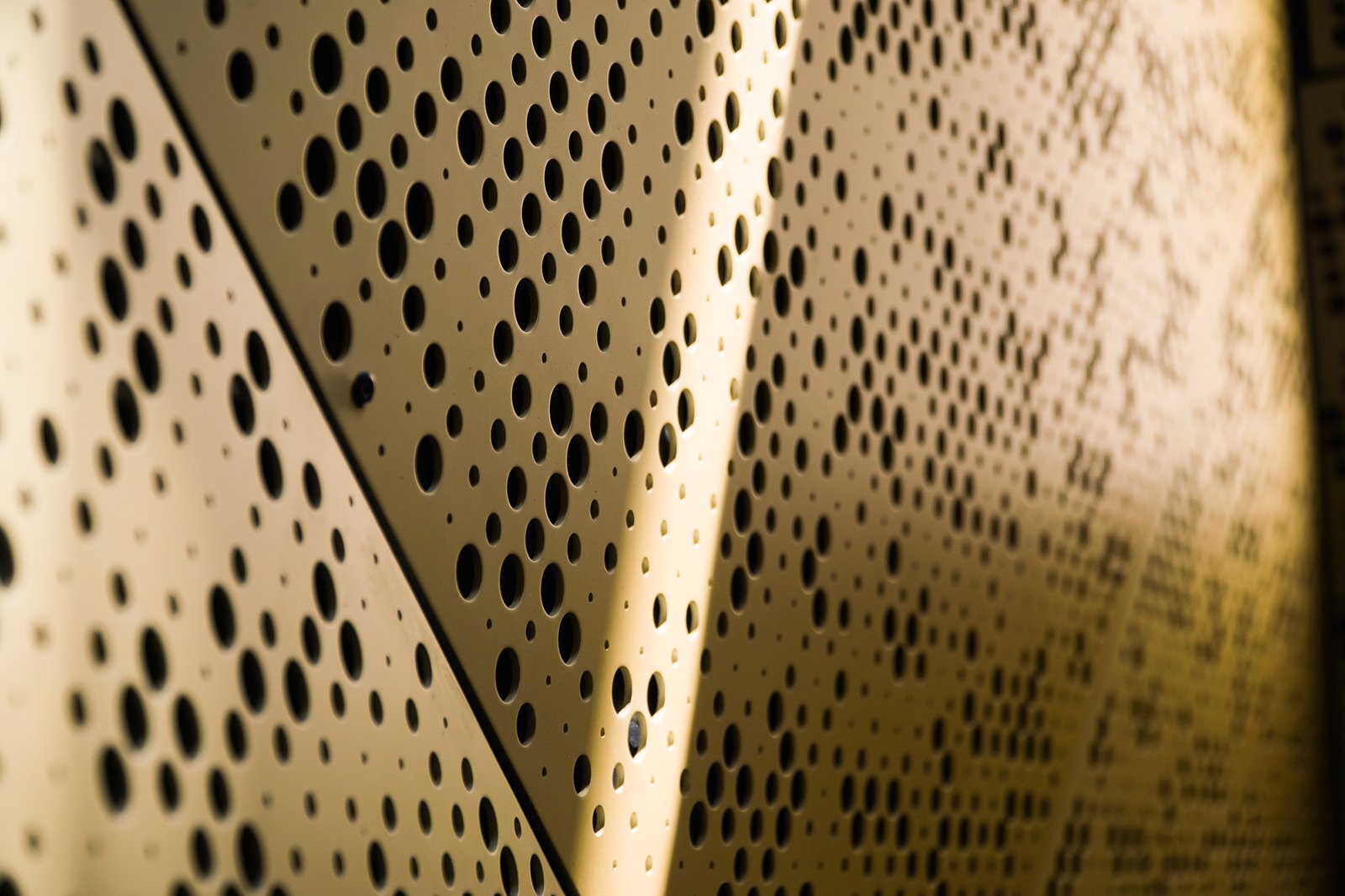

Perforated Metal Curtain Wall Panels

Perforated stainless steel wall panels, formerly known as perforated panels, are one of the most widely used products in the building’s facade curtain walls today, allowing light to penetrate while highlighting the products of modern facilities. The holes are formed on plates of different materials. Material can be stainless steel plate, aluminum plate, iron plate, copper plate, and the process of the various metal plate.

Through the different cutting to achieve the appropriate size in the CNC machine tool for perforating. To obtain the ideal pattern effect of the perforated plate, the designer will use the size of different perforations and density changes, as well as hole spacing and arrangement. Affecting the visual clarity of perforated staggered skin creates novel visual effects. The entire building facade effect, combined with perforating rate, plate thickness, and other factors to reduce solar radiation heat, reduce energy consumption role.

The use of light and shadow holes to express the building in the day and night to pass the overall visual sense and the modern sense of the city, most of the use outdoor buildings in the outer curtain wall, such as the opera, the library, the Museum of Art.

Shape Selection of

Perforated Metal Curtain Wall Panels

The setting of the different perforating rates of the decorative perforating plate will produce other visual effects in the application of building skin, indoor and outdoor, night and day.Hole types: round holes, square holes, prismatic holes, triangular holes, pentagram holes, long round holes, and other perforated plates. Designers usually, according to the meaning of the existence of the building, punching plate design various combinations of patterns to pass on the theme of the building to people. In real life, the application is pervasive, from the outside to the interior. Decorative perforated aluminum skin mainly expresses the effect on the rest of the building and can avoid the outdoor observation of indoor activities. When viewing from indoors to outdoors, perforated aluminum skin forms a certain degree of shelter to the outdoor landscape, and different perforating rates significantly differ in the degree of influence on the observation of the outdoor landscape.When the perforation rate is low, the perforated aluminum plate has a noticeable shielding effect on the outdoor scene. When the perforation rate is high, the human eye can still feel the outdoor landscape activity through the pores of the perforated plate.

Cross Holes

Circle and Star Holes

Circle Holes

Hexagon Holes

Size Circle Holes

Triangular Holes

Copper Coin Holes

Gator Mouth Holes

Long Round Holes

Petaloid Holes

Rectangle Holes

Square Holes

Specification of Perforated

Metal Curtain Wall Panels

Standard:JIS/AISI/ASTM/GB/DIN/EN

Materials:Stainless Steel Sheet, Aluminum Sheet, Iron Sheet, Copper Sheet

Thickness:0.8-3.0mm

Surface:Brushed, Powder Coating, Sand Blasting, Etc

Width:30-1850mm、Customizable

Color:Colorful

Length:1220-3000mm、Customizable

Application:Building Curtain Wall, Privacy Partition, Partition, Railing Panel

Service:Free Sample, One Stop Service

Packaging:Waterproof Paper + Wooden Case

Application of Perforated

Metal Curtain Wall Panels

The perforated metal plate used in architecture has various hole shapes and different arrangement ways, which are beautiful in form and outstanding in decoration. Architects and designers use their design ideas and concepts to create more architectural style and design art.

Facade Curtain Wall

Perforated stainless steel sheets echo the interior space through external lighting, giving a strong sense of artistic ambiance.

Ceiling Design

Perforated panels are used to design the ceiling in many different ways. The light from the sun and the lights penetrate through the perforated panels to create a warm-toned light. The overall feeling is relaxing and suitable for work and play.

Balcony Balustrades

Innovative balcony design, using a perforated metal plate, not only daylighting ventilation, can protect privacy and anti-fall.

Interior Decoration

Interior design patterns are decorated with perforated metal plates, which stack on top of each other to create a stunning hazy visual effect.

Partition Decoration

In the interior design, perforated plate, do partition space, partition, so that the brief space moment has a sense of innovation so that the area has permeability. When sunlight comes in through the perforated plates of different shapes, it creates a particular artistic effect with the changes of light and shadow.

Stair Decoration

The outdoor stairs are designed with perforated panels, and the lighting and space produce rich artistic changes.

Perforated panels are widely used in large public buildings such as railways, subways, movie theaters, television stations, and gymnasiums. As decorative perforated panels, they are not only beautiful but also attractive. And it also has sound absorption and noise reduction.

Advantages of Perforated

Metal Curtain Wall Panels

Improved Ventilation And Airflow

The main advantage of perforated panels is their ability to enhance ventilation and airflow in different spaces. Allowing air to pass through small holes effectively distributes fresh air and maintains optimal air circulation. This feature is particularly useful in areas that require appropriate ventilation, such as air conditioning systems, industrial equipment, electronic enclosures, and even architectural design. With the increase of airflow, the risk of overheating and equipment failure is greatly reduced.

Acoustic Advantages

Perforated panels are known for their acoustic properties. The presence of small holes enables them to absorb sound waves and reduce noise levels in various environments. This makes them very suitable for designing sound-absorbing surfaces in concert halls, recording studios, and theaters, as noise control in these areas is crucial. Perforated panels effectively reduce echoes and unnecessary noise reflections, creating a more favorable environment.

Versatility And Customization

Perforated panels provide exceptional versatility in design and customization. JYF Metal can produce various sizes, shapes, and hole types of plates to meet specific requirements. Provide customized solutions for industries such as architecture, interior design, and electronics. In addition, perforated plates can be made of various materials, such as aluminum, steel, stainless steel, and composite materials, ensuring compatibility with different environments and applications.

Enhanced Structural Strength

The carefully designed hole pattern will not affect the overall strength and integrity of the board. Perforation usually helps to improve the ratio of strength to weight, making it advantageous for applications that require lightweight and sturdy materials. This is particularly beneficial in industries such as construction, transportation, and aerospace, where strength and weight considerations play a crucial role.

Enhance Aesthetics

Perforated panels not only have functional advantages, but also have aesthetic advantages. The unique patterns created by Kong add strong visual appeal to any space. Perforated panels can be used as decorative elements for building facades, interior design elements, furniture, and even artistic installations. The combination of functional and visually pleasing design makes it a popular choice for various creativity and architecture.

Frequently Asked Questions

A1:Choosing alloy perforated panels is a good option as they are lightweight and possess good strength characteristics. Additionally, stainless steel perforated panels are also a common choice due to their high corrosion resistance and structural strength. The final selection should also consider factors like project budget, design requirements, and environmental conditions.

A2:Perforated panels are suitable for large buildings because they provide good ventilation and lighting effects, while also being decorative and practical. They are applicable for decorative and functional needs such as facades and ceilings of large buildings.

A3:

A stainless steel perforated plate is a metal sheet that has been punched or drilled with holes. These perforations vary in size, shape, and pattern, allowing for customized airflow, light filtration, or decorative effects.

A4:Stainless steel perforated plates are typically created by punching holes in the metal sheet using mechanical or hydraulic presses. Additionally, laser or plasma cutting technologies can be used to create precise perforations on the surface of stainless steel.

A5:Stainless steel perforated plates are used across various industries, including construction, automotive, filtration, acoustics, HVAC (heating, ventilation, and air conditioning), food processing, and decorative design. Their applications include screening, filtering, ventilating, and noise reduction.

A6:Stainless steel perforated plates come in various perforation patterns, including round, square, slotted, hexagonal, and decorative shapes. The choice of perforation pattern depends on the specific application requirements and desired aesthetic effects.

A7:Yes, stainless steel perforated plates can be customized to meet specific design requirements. Manufacturers offer custom options such as perforation patterns, hole sizes, shapes, spacings, sheet dimensions, and surface treatments, providing tailored solutions for different applications.

A8:Stainless steel perforated plates are typically installed using screws, bolts, or welding, depending on the application and surface. Maintenance includes regularly cleaning with mild soap and water to remove dirt and debris. Avoid using abrasive cleaners or harsh chemicals that might damage the stainless steel surface. Regular inspections ensure the perforated plates function properly and extend their lifespan.