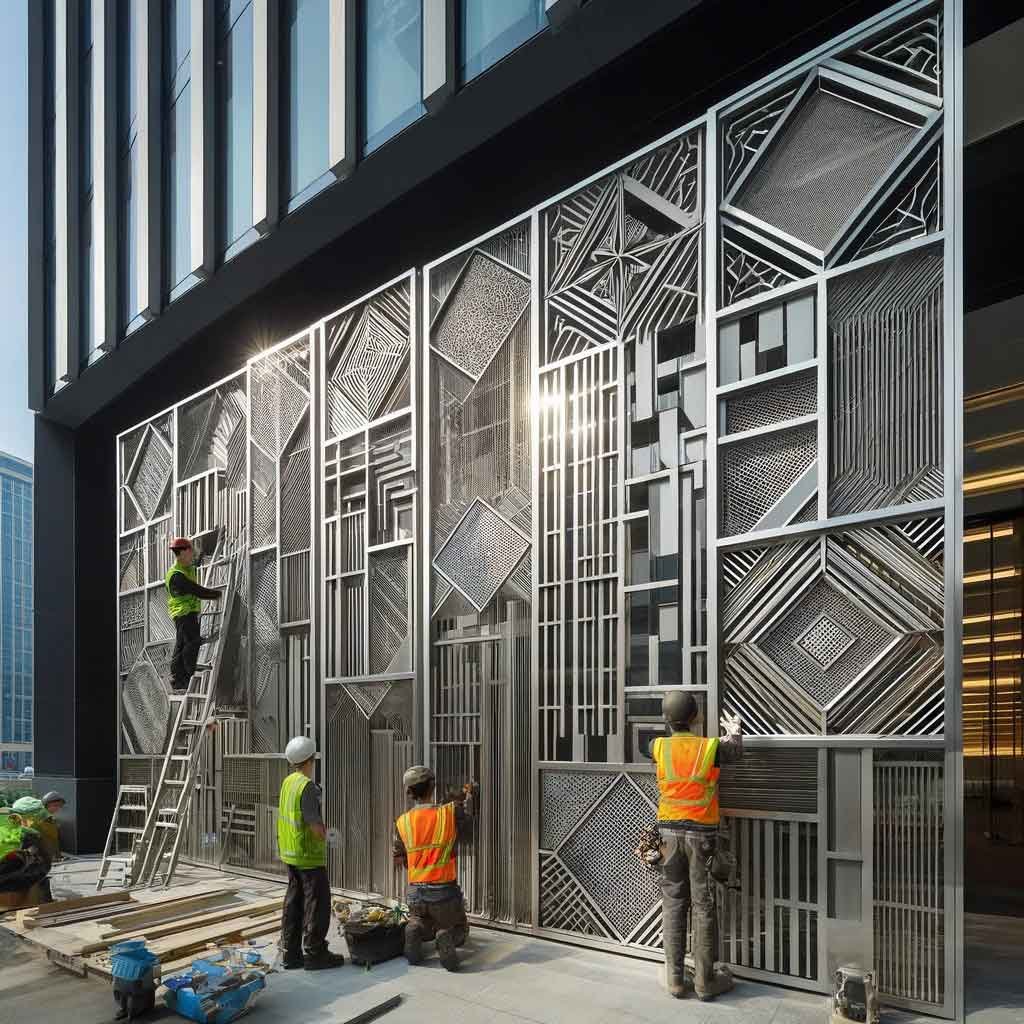

Navigating Metal Curtain Wall Construction: Tips and Guidelines

Table of Contents

Attention to Detail in Curtain Wall Construction

Storage and Transportation Considerations

- Metal plates (aluminum alloy and stainless steel) should be placed on the ground at an angle greater than 10°, supported by thick wooden plates.

- Always lift metal plates with two persons to prevent surface damage.

- Ensure the working table surface is clean and smooth to avoid scratching the metal plates.

On-Site Processing Attention

- While most curtain wall sheet metal is processed off-site, on-site processing may be necessary due to factory requirements.

- Use professional equipment and skilled personnel for on-site processing to maintain quality.

- Strictly follow fixed operations to prevent safety hazards during processing.

Safety Construction Technical Measures

- Wear helmets and seat belts for high-altitude work; refrain from bringing loose objects onto the construction site.

- Prohibit climbing on outer scaffolding; follow designated access points and construction schemes.

- Establish special guards if necessary to prevent personnel from passing beneath the working face of curtain wall installation.

- Employ material packages when welding to catch sparks and prevent fires.

- Install leakage protectors on motors and ensure operators of hand-held power tools wear insulating gloves.

- Implement protective measures for high-rise building curtain wall installations, including safety nets and protective devices.

- Conduct pre-shift meetings to discuss safety procedures.

- Strengthen safety supervision and promptly rectify any violations to prevent accidents.

- Prohibit high-altitude operations in adverse weather conditions.

- Prioritize safety education and maintain records of safety procedures for workers.

- Thoroughly inspect construction tools before use and conduct tests on safety protection devices.

- Handle sealing materials cautiously to prevent solvent poisoning and fire hazards.

Cleaning and Maintenance

- Determine cleaning frequency based on curtain wall surface dust pollution to avoid scratching.

- Promptly repair loose bolts, rusted welding parts, and damaged sealants.

- Replace or reinforce damaged curtain wall members and connectors as needed.

Regular Inspections

- Regularly inspect the curtain wall drainage system and clear blockages promptly.

- Conduct comprehensive inspections post-natural disasters and reinforce damaged curtain walls accordingly.

External Maintenance and Repair

- Avoid conducting maintenance and repair work during adverse weather conditions.

- Use firm, convenient, and safe equipment for inspection, cleaning, maintenance, and repair.

Adherence to National Standard JGJ80-2016

Ensure compliance with relevant regulations for maintenance and repair work on metal sheet curtain walls, particularly when working at height.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions