Key Features and Benefits of Stainless Steel Sculptures Worldwide

Table of Contents

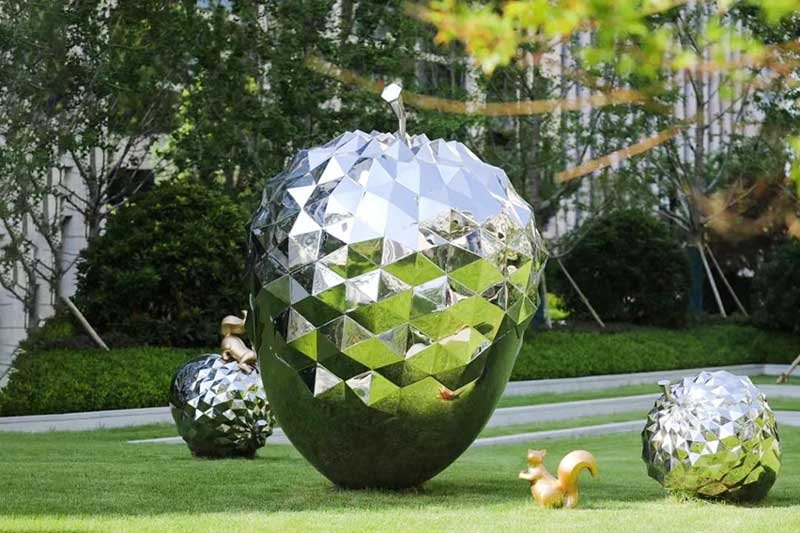

Stainless steel sculptures are increasingly sought after in both the USA and global art markets, revered for their striking visual appeal, exceptional durability, and versatility. This material’s unique ability to resist corrosion, coupled with its strength, makes it an ideal choice for both indoor and outdoor installations, particularly in environments subject to harsh weather conditions.

Modern art sculptures offer a modern, sleek aesthetic that blends well with diverse architectural settings, from urban landscapes to private collections. With the growing demand for long-lasting art pieces, stainless steel’s ability to maintain its beauty over time, alongside its ease of maintenance, positions it as a preferred choice for contemporary artists and collectors worldwide.

In this article, we will explore why they have become a staple in the art world both in the USA and beyond.

Why stainless steel is preferred by American sculptors ?

Stainless steel is a preferred material for sculptors in the USA due to its remarkable combination of strength, versatility, and aesthetic qualities. The material’s durability makes it ideal for both indoor and outdoor sculptures, as it is highly resistant to corrosion, rust, and weathering, ensuring that works of art can stand the test of time. This resilience is particularly beneficial in public art installations and sculptures displayed in urban environments.

Additionally, stainless steel’s reflective surface creates dynamic, eye-catching effects as it interacts with light, enhancing the sculpture’s visual appeal. The material is also malleable, allowing artists to create intricate designs and large-scale pieces with precision. Furthermore, stainless steel’s modern, sleek appearance fits well in contemporary art, providing an ideal canvas for sculptors who aim to push artistic boundaries while maintaining durability and elegance.

This combination of practicality and aesthetic appeal is why stainless steel has become a preferred choice for sculptors across the USA.

Effect of Sculpture Specifications on Quality Across Markets

The specifications of metal sculptures, particularly those crafted from stainless steel, play a crucial role in determining their quality and appeal in various markets. Key factors such as material grade, craftsmanship, customization, and surface treatment directly impact both the aesthetic and functional qualities of the artworks.

For instance, adherence to international standards like JIS, AISI, and ASTM ensures that the stainless steel used meets safety and performance criteria, which is especially important for crafted piece intended for public spaces or harsh environments. The choice of material grade also significantly influences the sculpture’s durability. Grade 304 is ideal for general applications, while Grade 316 offers superior corrosion resistance, particularly in marine or coastal settings, making it more desirable in markets where longevity is a key consideration.

Additionally, offering custom designs based on client specifications allows for greater artistic freedom and the creation of one-of-a-kind pieces that can cater to specific architectural themes or personal preferences, increasing the perceived value of the statue. The level of craftsmanship, such as hand-carving and polishing, enhances the sculpture’s aesthetic appeal, making it more attractive in markets that prioritize artistry and intricate detailing.

Moreover, size specifications, with customizable thickness ranging from 1.8 to 2.5mm, ensure the structural integrity of the sculpture, providing both durability and the opportunity for fine detailing.

Custom Stainless Steel Sculpture Design in Europe

The design process for custom stainless steel sculptures in Europe follows a well-structured approach that combines creativity with precision engineering to ensure that the final piece is both visually compelling and structurally sound. The process begins with concept development, where artists sketch and refine ideas, often incorporating input from clients to ensure the inox steel sculpture meets specific requirements. This collaborative phase helps clarify the artistic vision and sets the direction for the project.

Once the concept is established, the appropriate grade of stainless steel is selected based on the sculpture’s size, location, and desired finish. Factors such as strength, corrosion resistance, and aesthetic qualities are considered to choose the best material for the job. Detailed technical drawings and 3D models are then created, providing a clear blueprint of the sculpture’s dimensions and structural elements.

For larger or more complex sculptures, engineering input is often necessary to ensure stability and safety. This might involve calculations related to load-bearing or wind resistance, especially for polished metal sculpture placed outdoors or in public spaces. Once the design is finalized, artists collaborate with skilled fabricators to cut, weld, and finish the stainless steel according to the specifications. This phase requires careful attention to detail to achieve the desired aesthetic, whether through smooth polished finishes or textured surfaces.

Finally, after fabrication, the sculpture is installed at its designated location. This step requires careful positioning to ensure the piece integrates harmoniously with its surroundings, whether in a public plaza, gallery, or private space. Throughout the process, ongoing collaboration between artists, engineers, fabricators, and clients ensures the stainless steel art piece meets both artistic and functional expectations, creating a lasting and impactful work of art.

Technology for Reflective Steel Sculptures in Australia

In Australia, the creation of stainless steel artwork involves a blend of traditional craftsmanship and modern technology. Artists often rely on advanced fabrication techniques such as Computer-Aided Design (CAD) and 3D modeling to conceptualize their sculptures. Once the design is finalized, precise cutting methods like laser cutting or plasma cutting are employed to shape the stainless steel.

Welding techniques, including TIG (Tungsten Inert Gas) welding, are used for joining parts, ensuring structural integrity while maintaining a clean, polished finish. The process also involves bending, forming, and shaping the metal, utilizing hydraulic presses and rollers to achieve intricate designs. After the basic structure is formed, the surface is treated using methods like polishing, sandblasting, or applying a protective coating, enhancing both the aesthetic appeal and durability of the art object.

For high-end projects, such as large public art pieces, intricate assembly and installation processes are critical to ensuring the sculptures’ stability and long-term resilience.

Size and Thickness Impact Stainless Steel Sculptures Across Cultures

The size and thickness of reflective steel sculptures significantly influence their perception and impact across different cultures. In many cultures, the scale of a sculpture can symbolize various concepts such as power, reverence, or spiritual significance. Large metal artwork, such as monumental public artworks, often carry a sense of grandeur and authority, making them symbols of civic pride or historical importance.

For example, in Western countries, large stainless steel sculptures are often used in public spaces, reflecting modernity and innovation, while in other regions, they may represent an idealization of strength and resilience.

In contrast, smaller custom corrosion-resistant steel sculptures, which often have intricate details, are more commonly found in private collections and galleries. They tend to emphasize elegance, precision, and artistic mastery, appealing to cultures that value craftsmanship and subtlety.

The thickness of the metal also plays a vital role in determining the durability and aesthetic of a sculpture. Thicker stainless steel is preferred for public art that are intended to withstand environmental challenges, particularly in outdoor installations.

Cultures that emphasize permanence and resilience (such as those in Australia or Europe, where sculptures often face harsh weather conditions) may opt for thicker materials to ensure longevity. Conversely, thinner materials are used in more delicate designs or artistic structure intended for indoor environments.

Surface Finishes Options for Stainless Steel Sculptures in Global

High-grade metal sculptures are available with a variety of surface finishes, each offering unique aesthetic qualities and practical benefits that cater to different international markets. The main surface finishes used in the creation of stainless steel sculptures include:

Mirror Finish

This highly reflective surface is achieved through polishing techniques that leave the sculpture smooth and shiny, creating a mirror-like effect. It’s often used for modern art pieces and public installations in countries where cutting-edge design is valued. It enhances the visual appeal of chrome steel sculpture by reflecting light and surrounding environments, making them stand out in urban landscapes.

Brushed Finish

This finish creates a subtle texture on the surface, with light streaks that can vary depending on the type of brush used. It’s a popular choice in European and Australian markets for sculptures meant to blend elegance with a more understated appearance. Brushed finishes can help reduce the appearance of scratches and wear, making them ideal for decorative steel sculpture that are exposed to public touch or harsh environments.

Matte Finish

A more understated look, matte finishes provide a smooth but non-reflective surface. This finish is commonly used in artistic or architectural sculptures where subtlety and minimalism are the focus. It’s often chosen for sculptures that are intended to convey a sense of quiet elegance, as seen in both private collections and minimalist installations worldwide.

PVD Coating

Physical Vapor Deposition (PVD) is a high-tech finish that applies a thin film to the surface of stainless steel. This finish is favored in high-end markets like luxury art sculptures, offering both aesthetic appeal and durability. It also provides extra protection against corrosion, making it especially popular for corrosion resistant steel sculpture placed in outdoor or marine environments, such as those found in coastal regions.

Antique or Patina Finish

This surface treatment mimics the look of aged metal with various color tones. Some artists apply patinas to stainless steel sculpturesto give them an antique look, which is often preferred in traditional art markets or in sculptures intended for historical or rustic contexts.

Each of these finishes allows artists to shape the perception and durability of their beautiful metal sculptures, ensuring they meet the specific demands of the market, be it for luxury, durability, or aesthetic beauty. The choice of finish often depends on local cultural preferences and environmental factors, such as exposure to harsh weather or a desire for low-maintenance upkeep.

Conclusion

In conclusion, dynamic stainless steel sculptures represent a unique fusion of artistic expression and durable design, making them a favored choice in various cultural contexts around the world. The innovative technologies used in their creation, along with careful considerations of size, thickness, and surface finishes, enhance their appeal and functionality in urban environments.

As these sculptures continue to gain popularity, they not only enrich public spaces but also contribute to the dialogue around art, nature, and architecture. For those interested in exploring the possibilities of stainless steel for their projects, contact JYF Metal today to discover high-quality options and expert guidance tailored to your artistic vision.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions