How Metal Curtain Walls Enhance Aesthetics and Performance in High-Rises?

Table of Contents

In the realm of high-rise architecture, the facades of buildings play a crucial role in defining their character and functionality. One feature that has gained significant attention in recent years is the metal curtain wall. While it’s easy to admire the aesthetic appeal, there’s much more to these structures than meets the eye. So, how exactly do metal curtain walls enhance the performance and beauty of high-rise buildings?

Let’s dive deeper into their role and uncover why they’ve become a go-to solution for architects around the world.

What is a Metal Curtain Wall ?

A metal curtain wall is a non-load-bearing exterior facade system commonly used in modern high-rise buildings. It consists of a framework of metal panels, often aluminum or steel, which are affixed to the building’s structural framework. These walls serve primarily as an outer protective covering, not bearing any of the building’s load, but rather offering protection against the elements while allowing for design flexibility.

How Do Metal Curtain Walls Enhance High-Rise Building Design ?

Metal curtain walls are a defining feature of modern architecture, especially in high-rise buildings, contributing significantly to their aesthetic appeal. These walls not only serve functional purposes but also provide a striking visual impact that elevates the overall design of a building. Let’s explore how they transform the appearance of high-rise structures.

First and foremost, metal facade panels allow for sleek, uninterrupted surfaces that lend buildings a clean, contemporary look. The metal frames, often made of aluminum or steel, can be shaped and finished in a variety of ways, from matte to glossy surfaces, providing endless design possibilities. This adaptability allows architects to create facades that are both bold and visually dynamic.

Moreover, exterior metal wall panels offer the opportunity to integrate expansive glass panels, which create a seamless connection between the interior and the exterior environment. The transparency of the glass not only maximizes natural light within the building but also allows for breathtaking views from the upper floors. The reflective quality of the glass, combined with the metallic frame, gives the building a sophisticated, futuristic appearance, making it stand out in any city skyline.

Example

Take the example of the Burj Khalifa in Dubai, one of the tallest buildings in the world. Its stunning metal curtain wall system plays a critical role in the tower’s distinctive appearance. The combination of reflective glass and intricate metal panels creates a sleek, gleaming surface that changes with the light throughout the day.

The metal curtain wall not only enhances the building’s aesthetics but also supports its energy efficiency by minimizing heat absorption, while offering structural integrity in extreme weather conditions.

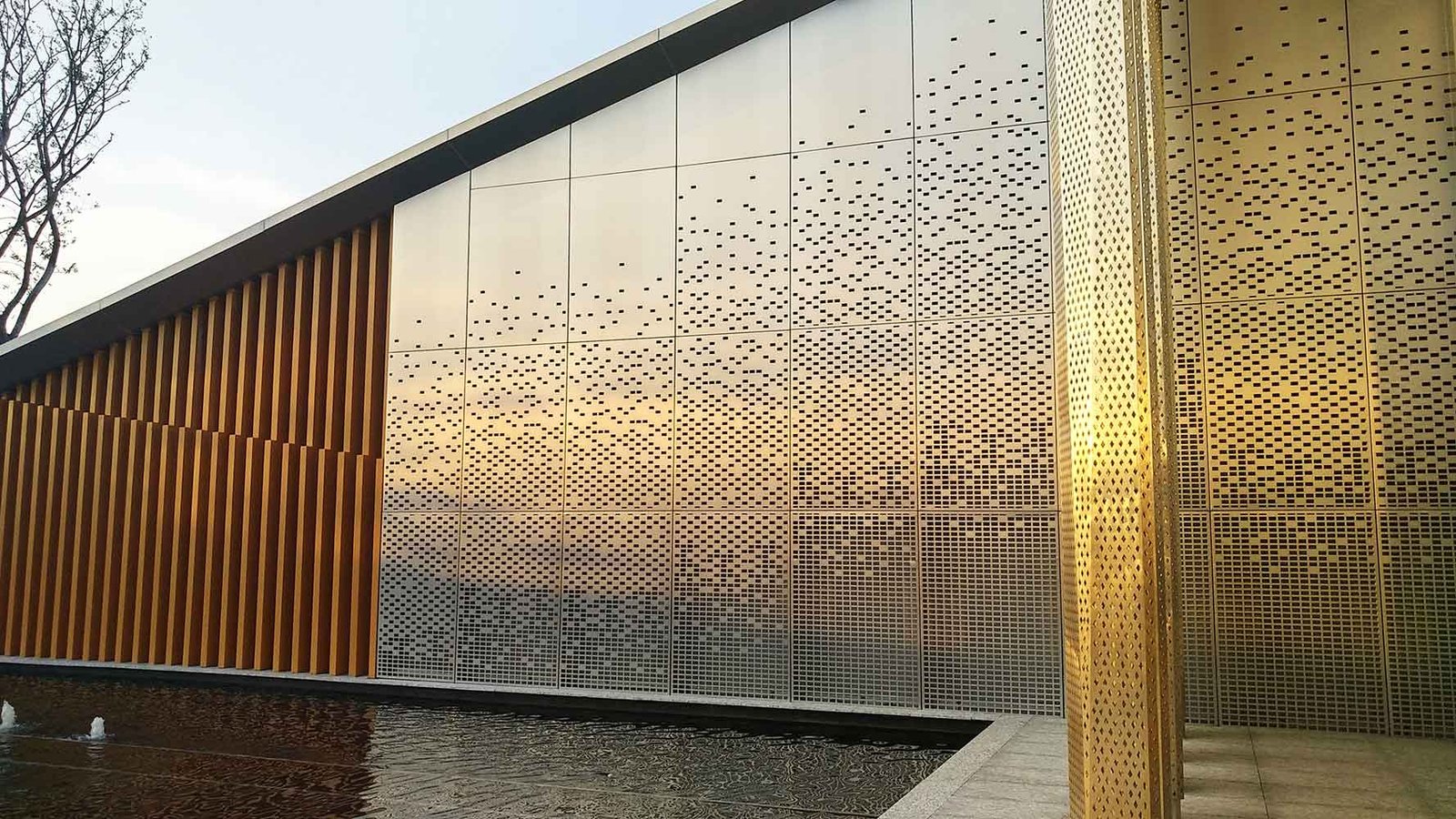

In addition to providing elegance, metal curtain walls can be customized to fit a building’s design theme, whether it’s a modern minimalist style or a more complex, textured facade. This flexibility has made them a go-to choice for architects aiming to create iconic, forward-thinking structures. From geometric patterns to artistic perforations, metal wall cladding offer a canvas for creative expression, making high-rise buildings not just functional spaces but works of art.

Why Do Architects Choose Perforated Metal Facades ?

Perforated metal curtain wall panels have become a popular choice for building facades due to their unique combination of aesthetic appeal, functionality, and versatility. These panels feature a series of carefully designed holes or perforations in the metal, which can be customized in various patterns and sizes to achieve specific visual effects and practical benefits.

Let’s dive into the key reasons why perforated metal curtain wall panels are favored in modern architecture.

Aesthetic Flexibility

One of the primary reasons for the popularity of perforated metal panels is their ability to enhance the visual appeal of a building. The perforations allow architects to create intricate, customized patterns, which can range from subtle designs to bold geometric shapes. These panels provide a striking contrast to smooth, flat surfaces, adding texture and depth to the building’s facade.

Enhanced Natural Light and Ventilation

The perforations in these panels allow for the passage of light and air, making them an excellent choice for buildings that aim to balance aesthetics with functionality. The holes can be designed to permit natural light to filter through, brightening the interior without compromising privacy.

Additionally, the open design enhances airflow, making the building’s facade more breathable, which can improve energy efficiency and reduce the need for artificial lighting and air conditioning.

Improved Privacy and Sun Control

Perforated metal panels can also provide an element of privacy without sacrificing visibility. Depending on the size and pattern of the perforations, the panels can obscure the view from the outside while still allowing occupants inside to enjoy views of the surroundings. Moreover, these panels can offer protection from harsh sunlight, reducing glare and heat gain while maintaining an open, airy feel.

This makes them particularly valuable in regions with intense sunlight or for buildings that prioritize sustainability.

Durability and Low Maintenance

Perforated metal panels are incredibly durable, often made from materials like stainless steel, aluminum, or copper, which are resistant to corrosion and harsh weather conditions. This longevity ensures that they maintain their aesthetic and functional benefits for many years with minimal upkeep.

Unlike other cladding materials, they don’t require frequent repainting or maintenance, making them a cost-effective option in the long run.

Customization and Branding Opportunities

Beyond their functional advantages, perforated metal panels offer unique branding opportunities for businesses. The perforation patterns can be customized to reflect a company’s logo, brand identity, or theme, turning the building’s facade into a powerful marketing tool.

This customization makes perforated metal facade a standout feature in commercial buildings, providing a distinctive, recognizable look.

Example

A great example of perforated metal curtain wall panels in action is the Mercedes-Benz Museum in Stuttgart, Germany. The museum’s striking facade uses perforated metal panels to create a dynamic, textured appearance that is both modern and artistic. The perforations help reduce the building’s energy consumption by allowing natural light to penetrate while also adding a visual element that ties into the museum’s branding and identity.

How Do Metal Curtain Walls Boost Natural Light and Ventilation?

Metal curtain walls play a crucial role in improving natural light and ventilation in high-rise buildings. By incorporating large glass panels or perforated metal sections, these curtain walls allow ample daylight to penetrate deep into the interior spaces, reducing the need for artificial lighting and enhancing the building’s energy efficiency.

The transparent nature of glass sections in the metal curtain wall system creates a seamless connection between the indoor environment and the outdoors, offering sweeping views and allowing sunlight to flood in, creating a bright and open atmosphere inside.

In addition to promoting natural light, steel curtain wall systems can be designed to optimize ventilation. Perforated metal panels, for example, allow air to circulate freely while still maintaining the structural integrity and aesthetic appeal of the building’s exterior. This ventilation helps regulate temperature and humidity levels, contributing to better indoor air quality and comfort for the building’s occupants.

Moreover, by reducing the reliance on artificial lighting and HVAC systems, metal curtain walls also contribute to the building’s overall sustainability, making them an ideal choice for modern, eco-conscious architecture.

Why Are Honeycomb Panels a Flexible Option for Metal Curtain Walls?

The customization of metal curtain walls with honeycomb plates significantly enhances design flexibility, offering architects and designers an innovative way to create both functional and aesthetically unique facades. Honeycomb plates are lightweight yet extremely durable, made from layers of metal that are formed into a honeycomb structure.

This design allows for greater strength with less material, providing the ability to create large, stable panels that can be customized to fit various building shapes and sizes.

By incorporating honeycomb plates into the metal curtain wall system, architects can achieve a high degree of design flexibility. The plates can be manufactured in a wide range of sizes, colors, and finishes, which allows for the creation of intricate patterns or sleek, minimalist designs.

This adaptability makes honeycomb plates ideal for achieving distinct visual effects, from geometric patterns to more organic, flowing designs that enhance the building’s overall aesthetic. Furthermore, the ability to integrate perforations or other custom features into the honeycomb structure allows for functional elements like light diffusion, privacy control, and even ventilation, all while maintaining a high-end, modern look.

This level of customization enables designers to push creative boundaries and tailor the building’s facade to specific design goals or brand identities, all while ensuring that the structure remains durable and efficient.

Conclusion

In conclusion, the customization of metal curtain walls with honeycomb plates offers unparalleled design flexibility, allowing architects to create visually stunning and functional facades. With options for intricate patterns, durable materials, and unique finishes, these customizable systems elevate the aesthetic appeal of high-rise buildings while enhancing performance in terms of strength, insulation, and ventilation.

If you’re looking to explore custom metal curtain wall options with honeycomb plates, contact JYF Metal today to get a quote and bring your architectural vision to life!

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions