Honeycomb Plate

Honeycomb Plate

Metal honeycomb panels can be designed and processed into various colors and shapes, and installed according to your needs through CAD drawing customization. With our manufacturing technology and years of experience, our honeycomb panels have high-quality quality and can meet the decoration needs of contractors and builders. In addition, our metal honeycomb panel products are durable, lightweight, cost-effective, and versatile. Colorful products not only provide a beautiful appearance for your project, but also make them more practical in your space.

Type of Honeycomb Plate

Metal honeycomb panels are a comprehensive material that meets engineering and design requirements. It not only has excellent performance characteristics, but also provides a unique appearance and practical solutions for projects. Whether applied in architecture, transportation, or housing design, metal honeycomb panels can contribute to the project and provide more possibilities for engineering and design.

Stainless Steel Honeycomb Panels

Metal honeycomb panel is a metal material composed of two metal panels and a thick layer of honeycomb-like new material. It is widely used in civil architecture and car and ship decoration. The panel is made of stainless steel and aluminum, with aluminum foil in the middle. Due to the high heat conduction value between aluminum skin and honeycomb......

More Details

Aluminum Honeycomb Panels

An aluminum honeycomb plate is two pieces of aluminum plate and honeycomb-like aluminum foil new material by hot pressing bonding metal materials. Because of its unique structure, the aluminum honeycomb panel has the lightest weight in the same volume as other materials and has outstanding stiffness and overall stability.Aluminum alloy is not radioactive and has environmental protection......

More Details

Characteristics of Stainless Steel Honeycomb Panels

Uniform Color

The surface of the honeycomb board is smooth and the color is uniform. Stainless steel honeycomb panel products adopt continuous rolling coating technology to complete color coating and improve the surface gloss of the product. Honeycomb panels have strong decorative effects and have been widely used in industries such as aerospace, subway, and construction.

Corrosion Resistance

Stainless steel honeycomb panels have high surface smoothness and temperature stability. Honeycomb panels can not only be made into flat plates, but also into single curved and hyperbolic plates. It has strong corrosion resistance, insulation, and environmental adaptability, making it very suitable for harsh application environments such as airports, railways, or passenger station control rooms. This durability means playing a significant role in developing a more sustainable society: improving energy efficiency, reducing pollution, and reducing the use of materials.

Performance Characteristics

Due to the wide application of stainless steel honeycomb panels, honeycomb panels can also be preferred for curtain wall decoration and metal materials. This can fully utilize the high bending strength of honeycomb panels. Compared with other metal panels, the size and usage of aluminum profiles can be appropriately reduced to ensure the overall smoothness of the roof and maintain good results for a long time.

Structural Characteristics

From panel materials, shapes, seams, installation systems, to colors and surface treatments, honeycomb panels provide designers with a wealth of choices. The honeycomb panel series has a wide range of product specifications and can provide various panel shapes, making it particularly suitable for large-scale layout applications. Its charm lies in the larger and smoother surface of the board.

Environment Protection

The aluminum honeycomb core in the stainless steel honeycomb panel is a honeycomb, which can prevent air circulation, heat, and acoustic expansion, and reduce the thermal conductivity and acoustic waves of the panel. Stainless steel honeycomb panel products are environmentally friendly, recyclable, and have a long service life. The selection of surface shapes and colors can be diverse. Fluorocarbon baking paint and wood grain transfer printing can be used for surface treatment processes, which can extend the service life of products to a certain extent.

Fireproof

In order to achieve good decorative and fireproof functions, stainless steel honeycomb panels can be surface coated or treated with composite fireproof panels according to various environmental needs. High fire resistance rating, good self extinguishing performance after a fire, low heat release value, can form a refractory layer, reduce the release of smoke and toxic gases, and have good environmental performance. The advantages of stainless steel honeycomb panels are smooth surface, chemical scar resistance, and uniform color.

Recyclable

Stainless steel is the material with the highest recycling rate among all materials. Some characteristics of stainless steel honeycomb panel make it the fastest growing material and an important solution to the sustainability challenges facing the world. In addition, the value of all alloying elements (not only nickel) provides a strong incentive to recycle these substances at the end of the lifespan of stainless steel products and reuse them for the production of stainless steel.

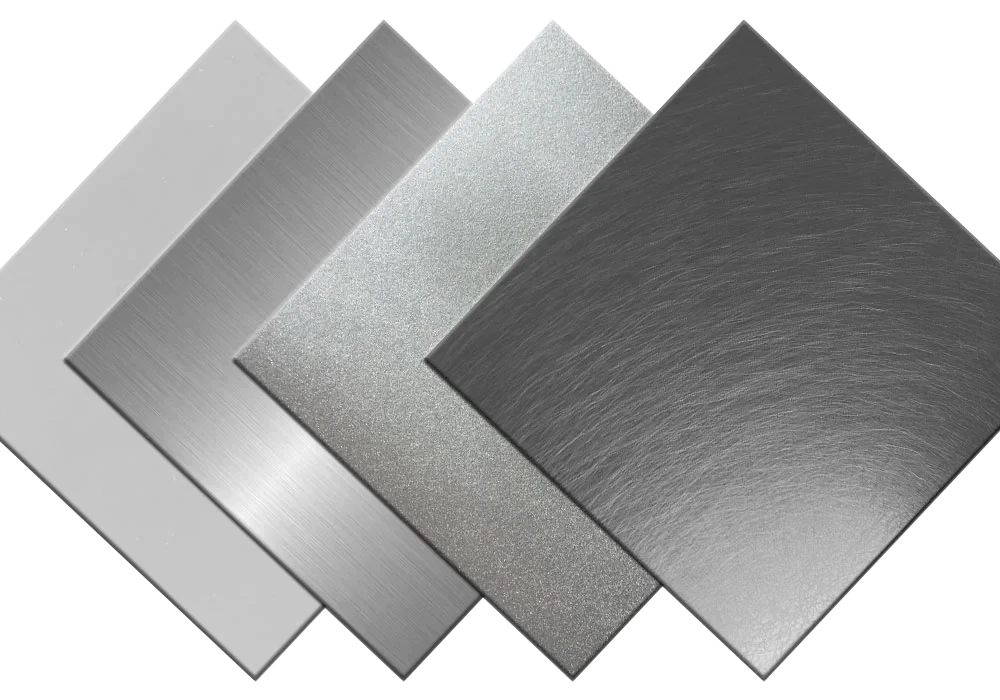

Surface Introduction

In modern architectural decoration, metal material is a new trend of technical aesthetics with permanent vitality. Metal engineering materials include steel, stainless steel, aluminum, copper, alloy materials, etc. Widely applied in construction engineering, metals have different properties such as density, corrosion resistance, tensile strength, plasticity, and so on. With rich experience in metal surface treatment and manufacturing, JYF Metal will serve you with sincerity and professionalism.

Surface Finish

The surface of metal sheets and products is treated by mechanical, physical, and chemical methods. Surface treatment varies in different properties.

- Mirror

- Brushed

- Sandblasted

- Anti fingerprints

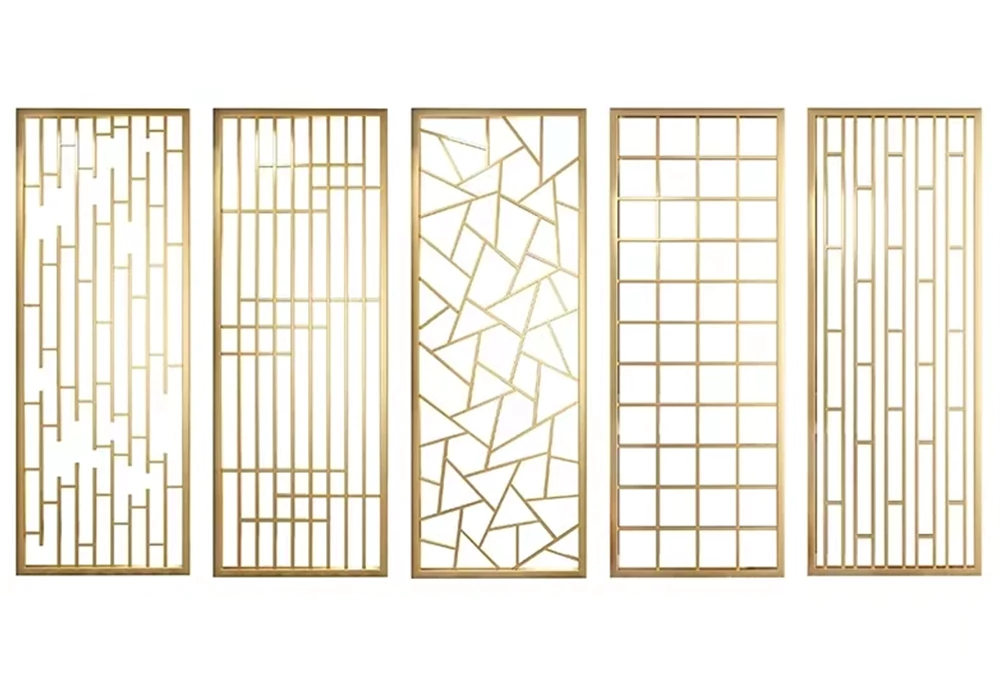

Attractive Pattern

Metal sheets and products can be designed and produced with various personalized patterns and patterns to meet designers' and architects' inspiration and space art.

- Engraving

- Hollowing

- Etching

- Embossing

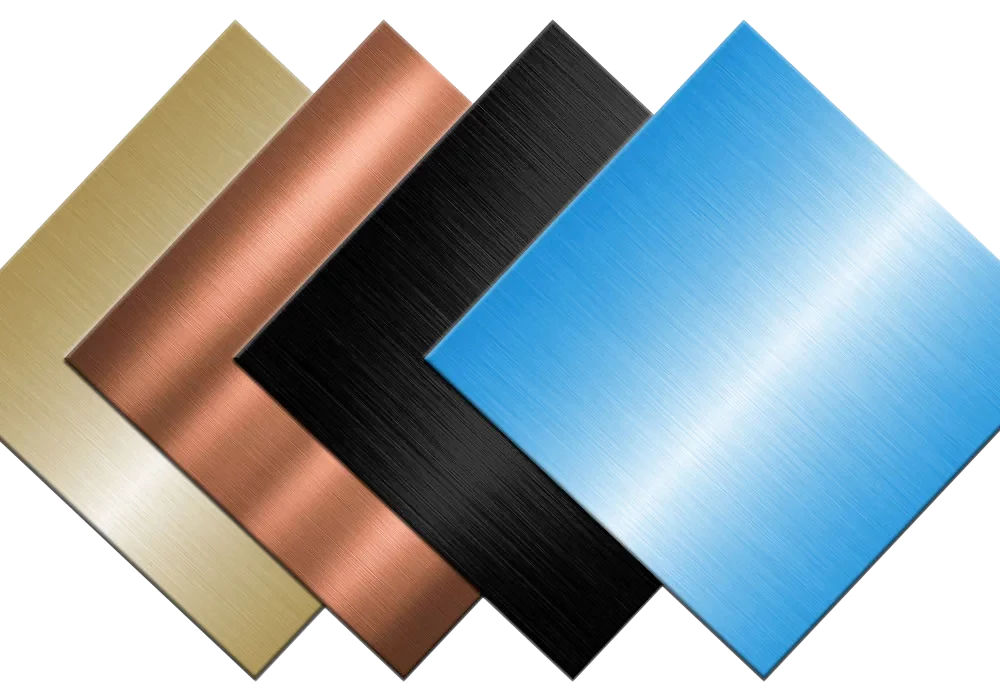

Fashion Color

According to metal characteristics and designs, various colors can be provided for your reference after completing the metal sheets and products to create a bright scene and a sense of the times.

- PVD Coating

- Electronic Coating

- Oxidation

- Spraying

Metal Molding

The metal material can process the perfect bending arc or the curved surface, the wave type, and so on, according to the design draft and the metal characteristic.

- Stamping

- Hammering

- Rolling

- Welding

Characteristics of Aluminum Honeycomb Panels

Lightweight, Low Density

The core layer of honeycomb panels is a typical porous structure, with continuous polygonal holes arranged in a regular periodic manner. Therefore, the cross-sectional area of the solid part of the honeycomb panel is very small, so its density is relatively small compared to other sandwich materials. Due to the fact that the density of honeycomb panels is much lower than that of ordinary panels such as laminated panels and steel plates, their mass is also the lightest when the volume is the same. Low density and lightweight make honeycomb panels well meet the requirements of aerospace engineering aircraft and transportation vehicles for materials that are "lightweight, energy-saving, and environmentally friendly".

High Strength And Good Rigidity

From a mechanical perspective, the honeycomb panel's structure bears resemblance to numerous I-beams connected together. The panel acts similarly to the I-beam's flange, primarily enduring in-plane loads, while the honeycomb core akin to the I-beam's web, mainly handles shear stress, linking, and supporting the top and bottom plates. Distinct from the I-beam's web, the honeycomb core is densely reinforced, not sparsely. It spans the entire panel's surface, with the core's height significantly surpassing the panel thickness. This design greatly amplifies the section's moment of inertia, markedly enhancing overall stability and stiffness.

Good Shock Resistance, Shock Absorption And Buffering Performance

When the honeycomb panel is subjected to an out of plane impact, it can convert the impact force into the plastic deformation energy of the honeycomb core, thus effectively absorbing the impact energy. By conducting a self falling ball impact experiment on the aluminum honeycomb panel, the area and depth of the dents at the impact site were observed, and it was found that there were no cracks at the impact site. This indicates that the aluminum honeycomb panel has good toughness and strong impact resistance, and can absorb most of the energy through its own deformation, resulting in good vibration reduction effect.

Thermal Insulation

Although the materials used in honeycomb panels, such as aluminum, do not inherently possess insulation or soundproofing properties, the unique structure of these panels ensures effective thermal and acoustic performance. The core's porous design, when combined with outer panels, creates hexagonal prism-shaped enclosed spaces, significantly restricting airflow, heat conduction, and sound wave propagation, thereby offering notable insulation and soundproofing qualities.

Good Fire And Moisture Resistance Performance

The panel and core layer of the aluminum honeycomb panel are made of aluminum alloy, which is a non flammable material and can play a good role in flame retardancy and fire prevention. In addition, aluminum alloy itself has good chemical stability, corrosion resistance, and moisture resistance.

Good Formability, Optional Thickness

The thickness of aluminum honeycomb panel can be 5-200mm according to the actual needs, and the shape can also be made into flat panel, single curved panel or double curved panel according to the specific requirements. Aluminum honeycomb panels not only have good formability, but also are not easily deformed after forming.

Pollution-free, Energy-saving And Environmentally Friendly

Aluminum alloy is a material used to prepare aluminum honeycomb panels. It is neither radioactive nor volatile of any harmful gases that are harmful to human health. It can also be fully recycled and reused, saving resources and energy, and is very in line with the requirements of energy conservation and environmental protection. In addition, honeycomb panels reduce the quality of transportation vehicles, improve power performance while ensuring strength, reduce fuel consumption, and save energy while reducing exhaust pollution.

Beautiful And Easy to Clean

The aluminum alloy panels of aluminum honeycomb panels can be used directly or coated with various colors or patterns on the surface.