FAQ

FAQ

Why Choose JYF Metal?

Q: Who is JYF Metal?

Q: Where is JYF Metal located?

Q: Are you a factory ?

Q: What industries does JYF Metal serve?

Architecture and Infrastructure: Provides high-strength, weather resistant stainless steel materials suitable for large building curtain walls and outdoor facilities.

Industrial manufacturing: providing corrosion-resistant and high-temperature resistant special metal components for machinery and equipment.

Business and Interior Design: Supply decorative stainless steel products, such as high-end furniture, hotel decoration, space design, etc., balancing aesthetics and functionality

Transportation: Providing lightweight and high durability metal components for industries such as automobiles, ships, and rail transit.

We ensure that every product can improve the efficiency and sustainability of customer projects through continuous technological research and development and customer demand analysis.

Q: What services do you offer ?

Our team collaborates closely with clients to create custom stainless steel products that match their exact specifications, ensuring precision and quality in every piece

Professional engineering services. From initial consultation to final production, we provide expert advice and technical assistance to ensure the best outcomes for your project.

Drawing production and analysis.

We produce detailed CAD drawings and perform thorough analysis to ensure accuracy and feasibility.

Design solutions based on installation location and environment.

Installation technical guidance

Q: What types of products do you specialize in?

Q: Can you provide custom design services?

Q: What material does JYF Metal use?

Stainless steel (grades 201, 304, 316, etc.) provides excellent strength, corrosion resistance, and wide applicability. Copper and brass have good conductivity, ductility, and decorative properties, making them suitable for scenes that balance functionality and aesthetics.

We offer a variety of surface treatment processes, such as: Brushing: presenting delicate textures, enhancing wear resistance and modernity.

Mirror polishing: creates a highly reflective and smooth surface, suitable for high-end decoration. Sandblasting: creates a matte texture and enhances scratch resistance. PVD coating: endowing metals with rich color and super durable surface characteristics through advanced technology.

These treatments not only enhance the durability and corrosion resistance of the product, but also meet the dual demands of aesthetics and functionality in the fields of architecture, industry, and design.

Q: What is PVD coating and what are its benefits for metal products?

Super durability: significantly extending the service life of metals, resisting wear, scratches, and chemical erosion.

Excellent anti-corrosion: provides a barrier for the substrate, suitable for harsh environments such as marine and chemical scenes.

Aesthetic diversity: can generate rich colors such as rose gold, champagne gold, black titanium, etc., and the color will last for a long time without fading.

Environmental safety: No harmful substance release, in line with modern sustainable manufacturing standards. PVD coating technology enables metal products to combine performance and visual expression in building curtain walls, industrial components, and high-end design products, making them an ideal choice for high-end applications.

Q: How do you ensure the quality of your products?

Q: How can I request a quote for a custom project ?

Q: What about the samples ?

The freight fee cost is by customer, generally we send by freight collect.

Q: What is MOQ ?

Stainless steel decorative sheet is 15 pieces and stainless steel tile trim is 500 pieces. There is no MOQ for other customized products.

Q: Can you produce large architectural elements ?

Q: What are your shipping options?

Q: What is the production time for your products ?

Stainless steel edge trims: Approximately 15 days.

Screen partitions and sculptures: 20-25 days.

Other customized products: 20-25 days.

The exact production time depends on the order quantity and complexity.

Q: How can I track my order?

Q: What is your payment terms ?

For project orders, in addition to the 40% deposit, progress payments will be collected based on production progress as well as shipment. The balance is paid before shipment.

Q: What packaging do you use?

Q: Does JYF Metal provide installation services?

Product Installation Technical Guidance Document

Installation scheme consulting service

Installation precautions instructions

Common problem solutions

We recommend that customers carefully read our product installation guide before installation. If they have any technical questions, our engineering team is always ready to provide professional advice to ensure a smooth installation process. For special or complex installation requirements, we can provide customized technical solutions.

For detailed technical support, please contact our customer service team and we will arrange professional technical assistance for you

Q: How should I maintain the stainless steel surface?

Q: Are your metal products corrosion-resistant?

Q: How can I contact JYF Metal for inquiries?

Phone:+86 133 8020 9777

E-mail: Lucky.CEO@jyfmetal.com

You can also contact us by filling in your detailed information through our contact form. Our customer service team will respond to all inquiries within 24 hours. You can contact our customer service for assistance, and we usually reply within 24 hours of working hours.

Surface Introduction

In modern architectural decoration, metal material is a new trend of technical aesthetics with permanent vitality. Metal engineering materials include steel, stainless steel, aluminum, copper, alloy materials, etc. Widely applied in construction engineering, metals have different properties such as density, corrosion resistance, tensile strength, plasticity, and so on. With rich experience in metal surface treatment and manufacturing, JYF Metal will serve you with sincerity and professionalism.

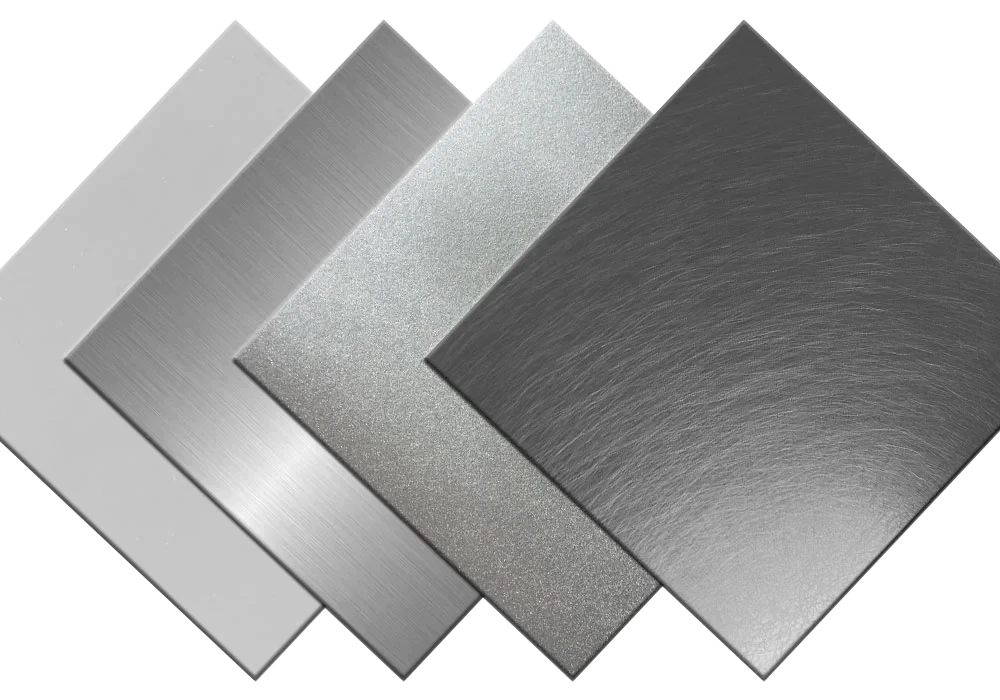

Surface Finish

The surface of metal sheets and products is treated by mechanical, physical, and chemical methods. Surface treatment varies in different properties.

- Mirror

- Brushed

- Sandblasted

- Anti fingerprints

- Mirror

- Brushed

- Sandblasted

- Anti fingerprints

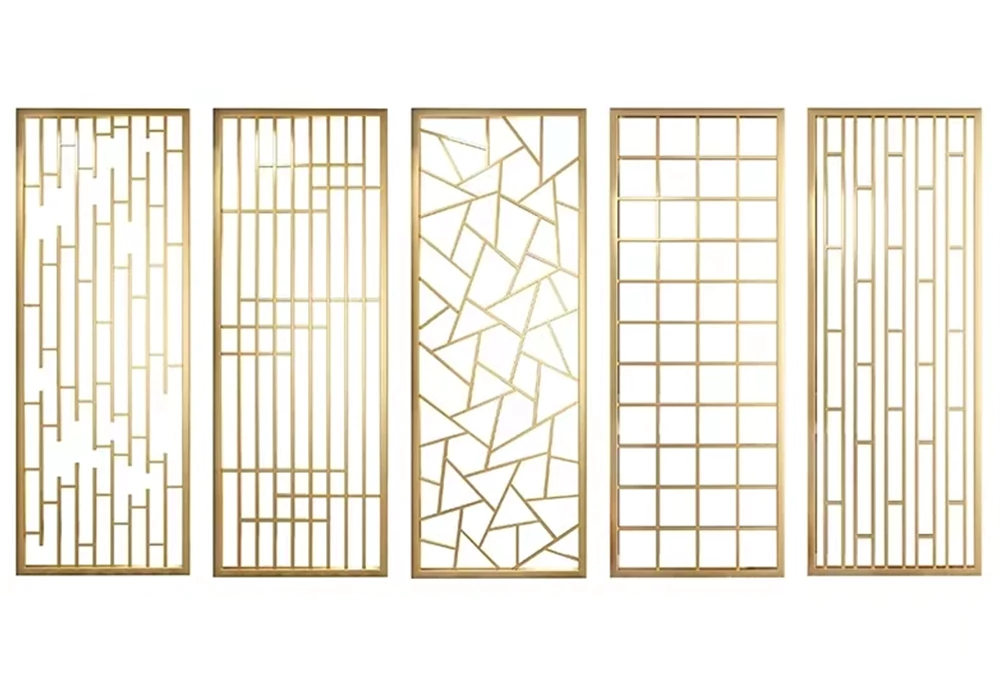

Attractive Pattern

Metal sheets and products can be designed and produced with various personalized patterns and patterns to meet designers' and architects' inspiration and space art.

- Engraving

- Hollowing

- Etching

- Embossing

- Engraving

- Hollowing

- Etching

- Embossing

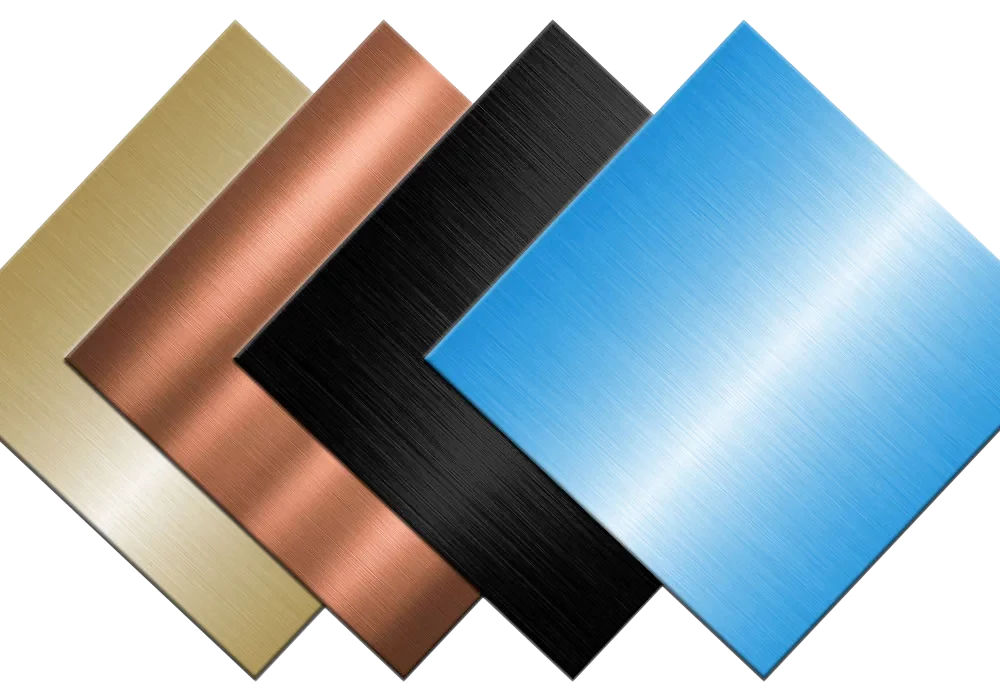

Fashion Color

According to metal characteristics and designs, various colors can be provided for your reference after completing the metal sheets and products to create a bright scene and a sense of the times.

- PVD Coating

- Electronic Coating

- Oxidation

- Spraying

- PVD Coating

- Electronic Coating

- Oxidation

- Spraying

Metal Molding

The metal material can process the perfect bending arc or the curved surface, the wave type, and so on, according to the design draft and the metal characteristic.

- Stamping

- Hammering

- Rolling

- Welding

- Stamping

- Hammering

- Rolling

- Welding