Fabrication

Customized Service for Stainless Steel

and Aluminum Products

JYF Metal specializes in providing stainless steel and aluminum products for construction projects and decorative engineering to highlight the charm of China’s manufacturing. Most team members have rich experience in R & D. Graduated from metal materials and metal surface treatment professional institutions in college, our team is good at bringing maximum benefits by adjusting product structures. Different products will be customized according to the metal characteristics, and other project requirements and installation need different manufacturing processes to ensure the project’s practicality, safety, scientific, and design. Our team provided customized metal, wooden, glass, and marble products in past projects. In the manufacturing process, we are good at combining the characteristics of different materials with metals, which are well received by our customers and designers. Concerning the diversity of metal sheet fabrication schemes and surface treatment applications, we will give you a sense of the metal world’s width at the project’s beginning.

Metal Cutting

Cutting is an indispensable part of the construction project as cutting is a method to make customized sizes and shapes per customers’ needs. Cutting methods include shearing, punching, laser cutting, water cutting, and plasma cutting. Different cutting ways vary for additional product requirements. As for JYF metal, we pay more attention to the precision of the cutting and the smoothness of the section.

Metal Connections

As one of the essential parts in metal processing, metal connections can be customized by manual welding, machine welding, folding joints and riveting, etc., according to the project cost budget, convenient transportation, installation, and application. We pay more attention to the practicability, aesthetics, and firmness of the product, cost, and application.

Metal Forming

According to the different needs of construction projects, metal and stainless steel need to be deepened into various shapes and forms through mechanical, electrical, and hydraulic tools. The method of forming is mainly dependent on product quality and installation. Typical processes include bending, rolling, curling, stretching, and hammering. In the whole molding process, we are more concerned about the size and radian after molding, installation adaptability, and so on.

Metal Surface Treatment

Color and product surface is essential to space design elements in architectural decoration projects. The surface and color of sheet metal can be selected according to engineering requirements to satisfy vision and enhance corrosion resistance and hardness. Metal and its surface treatment process include PVD vacuum coating, brushing, mirroring, etching, sandblasting, and spraying.

Surface Introduction

In modern architectural decoration, metal material is a new trend of technical aesthetics with permanent vitality. Metal engineering materials include steel, stainless steel, aluminum, copper, alloy materials, etc. Widely applied in construction engineering, metals have different properties such as density, corrosion resistance, tensile strength, plasticity, and so on. With rich experience in metal surface treatment and manufacturing, JYF Metal will serve you with sincerity and professionalism.

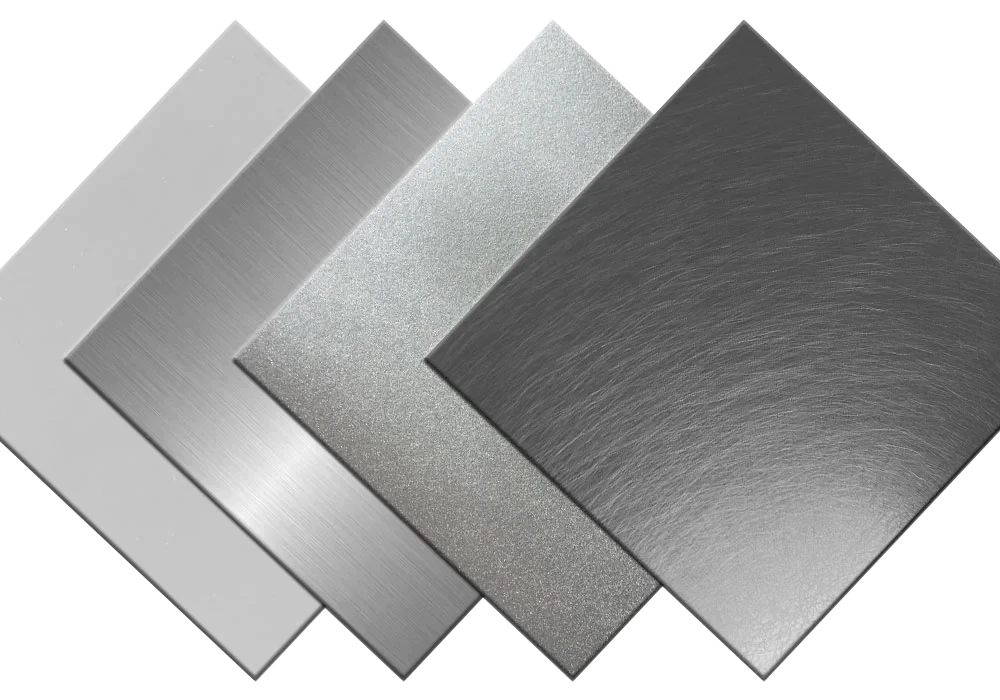

Surface Finish

The surface of metal sheets and products is treated by mechanical, physical, and chemical methods. Surface treatment varies in different properties.

- Mirror

- Brushed

- Sandblasted

- Anti fingerprints

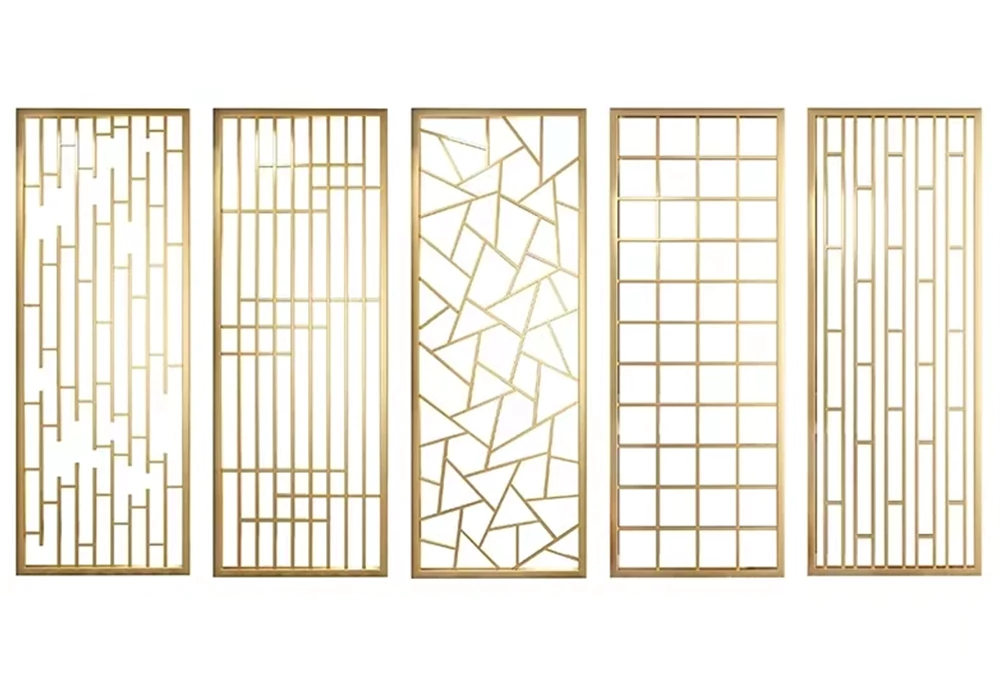

Attractive Pattern

Metal sheets and products can be designed and produced with various personalized patterns and patterns to meet designers' and architects' inspiration and space art.

- Engraving

- Hollowing

- Etching

- Embossing

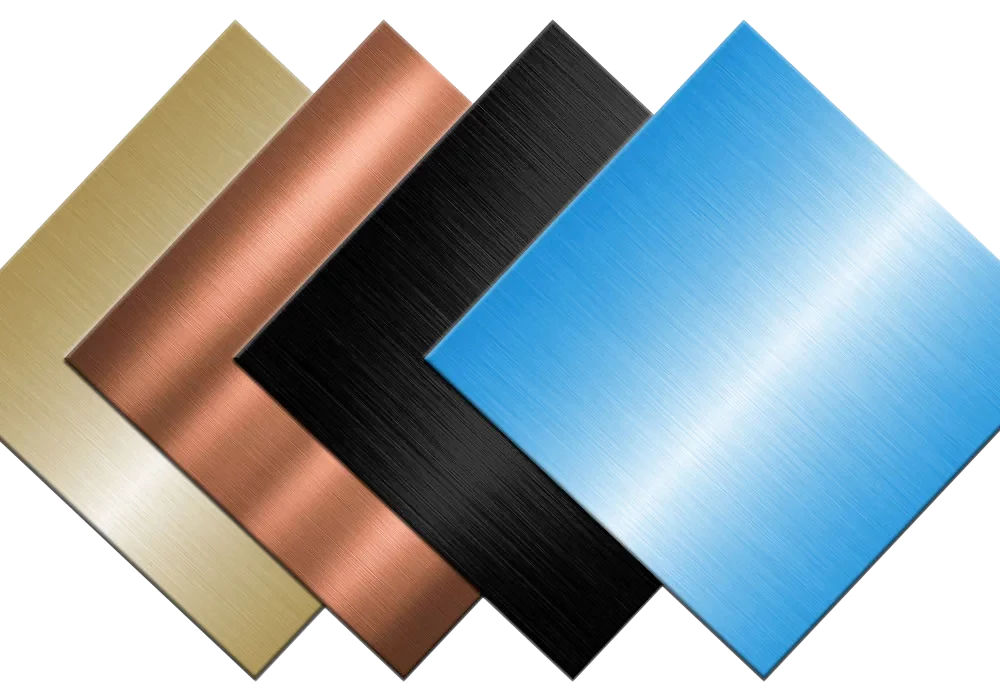

Fashion Color

According to metal characteristics and designs, various colors can be provided for your reference after completing the metal sheets and products to create a bright scene and a sense of the times.

- PVD Coating

- Electronic Coating

- Oxidation

- Spraying

Metal Molding

The metal material can process the perfect bending arc or the curved surface, the wave type, and so on, according to the design draft and the metal characteristic.

- Stamping

- Hammering

- Rolling

- Welding