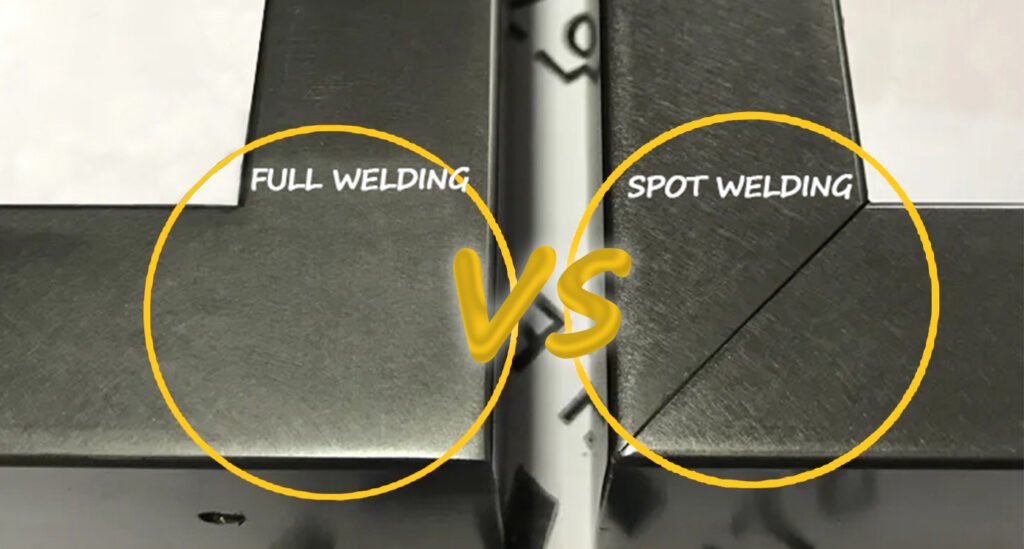

Exploring Welding Techniques for Stainless Steel Room Partitions: Spot Welding vs. Full Welding

Table of Contents

Stainless steel room partitions have become indispensable in various sectors, be it for creating privacy barriers, ensuring security, or aesthetic design. Their popularity can be attributed to multiple factors such as durability, longevity, and the polished appearance that they bring to a space. To achieve optimal results, the welding process used in their fabrication becomes critically important. This article provides a detailed comparison between the two most commonly employed welding techniques for stainless steel room partitions: spot welding and full welding.

Spot Welding: Unpacking the Methodology

Fundamentals of Spot Welding

Spot welding refers to the welding of two workpieces at a few important points where they need to be joined. Spot welding requires the welded metal to have good plasticity. For example, if you want to display two metal plates at right angles, you only need to weld two or three points. That is to say, as long as there is a certain distance between welding, it is spot welding. The solder joint has good fusion, a tighter interface, and a firm solder joint, but the interface of spot welding will leave gaps, also known as seam welding.

Perks of Using Spot Welding

Swift and Precise: The hallmark of spot welding lies in its speed and precision. The intense focus of current at a singular point minimizes heat dispersal, preserving the original integrity of the surrounding metal and mitigating the risks of warping or overheating.

Economical Aspects: Spot welding does not necessitate specialized consumables or equipment, thus minimizing operational costs. Moreover, its low power consumption adds another layer of cost-efficiency to the entire process.

Geometrical Adaptability: The nature of spot welding enables it to accommodate complex shapes and angles, making it a versatile choice for projects that demand architectural intricacies.

Limitations of Spot Welding

Strength Compromises: While fast, spot welding often produces bonds that lack in tensile strength and may not be suitable for applications that require durable and permanent bonds.

Confinement to Small Areas: Due to its localized approach, the utility of spot welding may be limited in projects that require large-scale welding.

Potential Material Impairment: The high concentration of heat and force in a limited area could lead to adverse effects like discoloration or even structural deformities.

Full Welding: A Comprehensive Approach

Essence of Full Welding

Contrary to spot welding, full welding aims to create a continuous, robust seam that provides an enduring bond between metal pieces. This makes it an ideal method for applications where structural integrity is a priority. Full welding, also known as full welding, involves welding all the contact points of two workpieces together. For example, when two stainless steel plates are spliced together and the joint is fully welded, that is, there is no gap in the joint, which is called full welding. Full welding requires high welding strength and is suitable for equipment that is subjected to strong impacts, vibrations, and heavy loads during operation. In terms of process, full welding requires a lot of time and effort, so the cost is slightly higher than spot welding.

Benefits of Full Welding

Unbeatable Strength: Full welding achieves remarkable levels of bond strength, making the partitions virtually impenetrable and highly resistant to physical deformities.

Augmented Durability: The welded joints are even less susceptible to corrosion than the individual stainless steel pieces, amplifying the partition’s lifespan.

Artistic License: With full welding, the sky’s the limit in design possibilities. The seamless joints and the absence of protruding fasteners allow for a sleek, finished look.

Long-term Cost Benefits: Despite high upfront costs, the long-lasting and low-maintenance nature of fully welded partitions can render them more economical over time.

Limitations of Spot Welding

Technical Mastery Required: Full welding demands a highly skilled workforce and sophisticated equipment, factors that contribute to its initial cost.

Safety Measures: The process comes with its own set of hazards including exposure to harmful fumes and potential fire risks, necessitating rigorous safety protocols.

Time Investment: The exacting nature of full welding requires thorough planning, execution, and quality checks, making it a lengthier process compared to spot welding.

Conclusion: Making the Right Choice

The choice of welding process ultimately rests on the specific requirements of your project. Spot welding shines in scenarios demanding quick and cost-effective solutions, while full welding is preferable for projects that require robustness and aesthetic sophistication. Regardless of the method chosen, the quality of the weld is paramount. This depends on several factors, including the apt choice of welding machine and the meticulous preparation of the metals to be joined.

By carefully weighing the pros and cons of each method, and by adhering to best practices in welding technique and safety, you can craft a durable, functional, and visually appealing stainless steel room partition.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions