Embossed Stainless Steel Sheet VS. Etched Stainless Steel Sheet

Table of Contents

Stainless steel sheets are widely used in various applications due to their corrosion resistance, durability, and aesthetic appeal. One way to enhance the appearance of stainless steel sheets is through surface treatment techniques such as embossing and etching. Embossed stainless steel sheets have raised or depressed patterns that add texture and dimension to the surface of the sheet, while etched stainless steel sheets have designs or patterns that are chemically engraved into the surface.

Both techniques provide unique decorative and functional finishes to stainless steel sheets and are commonly used in various industries, including architecture, automotive, and construction. By understanding the differences between embossed and etched stainless steel sheets, one can choose the best technique based on their desired application and design.

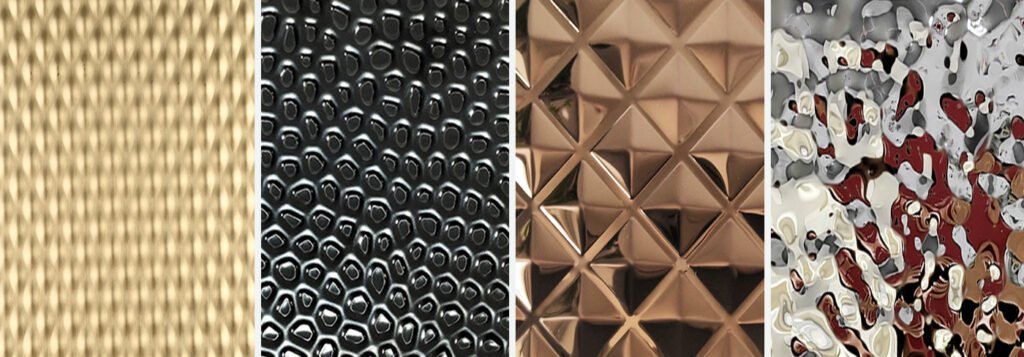

Embossed Stainless Steel Sheets

Die Stamping for Embossed Stainless Steel Sheets

Die stamping is a technique used to create a three-dimensional pattern on the surface of a stainless steel sheet by pressing it between two dies. A die is a specialized tool that is created to produce a specific shape or pattern. In die stamping, the stainless steel sheet is first placed between the two dies, and then a hydraulic press applies pressure to emboss the sheet with the pattern.

Die stamping is a highly precise technique that offers excellent repeatability, which means that the same pattern can be accurately reproduced on multiple sheets. The technique is also versatile, as it allows for a wide range of patterns and designs to be created. Moreover, die-stamped stainless steel sheets are highly durable and resistant to wear and tear, making them ideal for use in high-traffic areas.

Among all embossed patterns, water ripple stainelss steel sheet is the most popular.

Roller Stamping for Embossed Stainless Steel Sheets

Roller stamping is another technique used to create embossed stainless steel sheets. In this technique, a patterned roller is used to press the stainless steel sheet against a flat surface, creating a raised or depressed pattern on the surface of the sheet.

Roller stamping is a cost-effective technique that is suitable for smaller production runs. The technique allows for a wide range of patterns and designs to be created, depending on the patterned roller used. However, the technique is less precise than die stamping, as it may result in slight variations in the pattern or design. Roller-stamped stainless steel sheets are also more susceptible to wear and tear than die-stamped sheets.

Applications of Embossed Stainless Steel Sheets

Embossed stainless steel sheets are commonly used in a wide range of industries, including architecture, automotive, and construction. The textured surface of the sheets provides added visual interest and can be used to create striking visual statements in various applications.

Architecture – Embossed stainless steel sheets are widely used for wall cladding, ceilings, and elevator interiors. The embossed patterns add texture and dimension to the surfaces, creating an elegant and sophisticated look. Water ripple stainless steel sheet is most stunning, and any designers will choose it for wall or ceiling decoration.

Automotive industry – Embossed stainless steel sheets are used for interior and exterior trim, such as dashboards, spoilers, and grilles. The embossed patterns can be customized to the desired design, adding a unique touch to the car’s aesthetic.

Construction – Embossed stainless steel sheets are used for kitchen equipment, countertops, and backsplashes. The textured surface of the sheets provides added grip, making them ideal for high-traffic areas. Regular and dense embossing patterns are common, such as millet grains or skateboards.

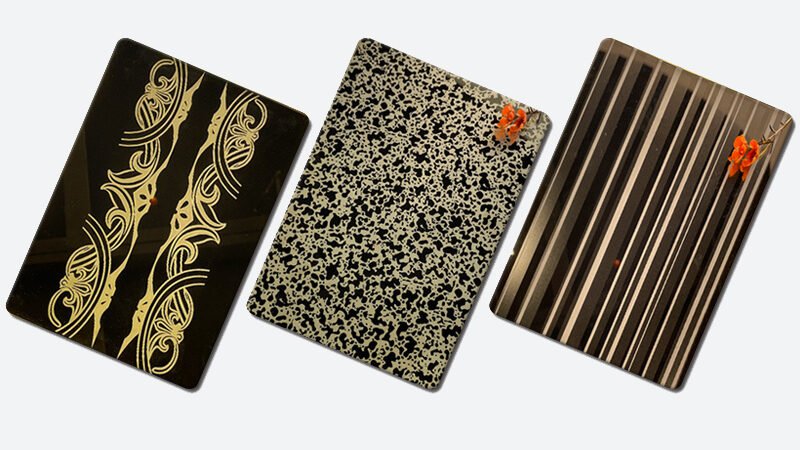

Etched Stainless Steel Sheets

Etching is a surface treatment technique used to create patterns or designs on the surface of stainless steel sheets. The etching process uses acid or chemicals to dissolve the surface layer of the metal, resulting in a design or pattern engraved into the surface of the sheet. The etching process involves several steps, including:

Preparing the Surface – The surface of the stainless steel sheet is thoroughly cleaned and degreased to remove any contaminants or impurities.

Applying the Masking Material – A masking material, usually made of a photosensitive material or vinyl, is applied to the surface of the sheet. The masking material protects the areas that should remain unetched by the acid or chemical.

Exposing the Masking Material – The sheet is then exposed to light, which activates the photosensitive material or vinyl, hardening the areas that should remain protected from the chemical.

Etching – The sheet is then submerged in the etchant solution, usually a caustic acid such as ferric chloride or nitric acid, which dissolves the unprotected areas of the metal, leaving behind the desired design or pattern.

Post-Etching Treatment – The sheet is then cleaned and thoroughly rinsed to remove any remaining chemical residue, and the masking material is removed, revealing the final design.

Applications of Etched Stainless Steel Sheets

Etched stainless steel sheets are commonly used in various industries for their unique aesthetic appeal and durability. The etched patterns or designs can be customized to match the desired design or application. Some common applications of etched stainless steel sheets include:

Signage – Etched stainless steel sheets are widely used in signage applications, such as nameplates, logos, and directional signs. The etched designs can be filled with paint or enamel to make the signage more visible.

Backsplashes – Etched stainless steel sheets are ideal for backsplashes in kitchens or bathrooms. The etched designs can add a unique touch to the area and are easy to clean.

Elevator Interiors – Etched stainless steel sheets are commonly used in elevator interiors to add texture and dimension to the surfaces. The etched patterns can also be customized to match the interior design of the building.

Architectural Panels – Etched stainless steel sheets are widely used in architecture for wall cladding panels. The textured surface adds interest and sophistication to the building’s facade.

Identify Embossed and Etched Stainless Steel Sheets

Observe the surface

The surface of an embossed stainless steel sheet will have a raised or depressed pattern that is three-dimensional and typically visible from different angles. The surface of an etched stainless steel sheet will have a flat design engraved into the metal.

Check the edges of the sheet

An embossed stainless steel sheet will typically have smoother, rounded edges due to the mechanical process used to create the pattern. An etched stainless steel sheet will have sharper, more defined edges due to the chemical process used to create the design Moreover, the embossed stainless steel sheet will warp up, while the etched stainless steel sheet is still a straight plate.

Look for uniformity

Embossed stainless steel sheets will have a uniform pattern across the entire surface of the sheet. Etched stainless steel sheets may have variations in the design due to the acid or chemical being used in the process.

Consider the color and reflection

Embossed stainless steel sheets can have a shiny, reflective surface that enhances the pattern. Etched stainless steel sheets may have a matte or satin finish due to the chemical process used to create the design.

In Conclusion

Both embossed and etched stainless steel sheet surface treatments offer unique decorative and functional finishes to stainless steel sheets. Embossed stainless steel sheet provides a three-dimensional pattern that is long-lasting and commonly used in architectural applications, while etched stainless steel sheet offers a flat engraved pattern that is often used for decorative purposes. The choice between embossed and etched stainless steel sheet ultimately depends on the desired application and design.

You Might Also Like

Please Share This

Recent Posts

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Stainless Steel Screens in Hotel Spaces: Design Strategies and Applications

- Large Stainless Steel Planters for Architectural and Commercial Landscape Projects

- Stainless Steel Outdoor Railings: Engineered for Durability, Designed for Style

- Metal Outdoor Signage: Durable, Customizable, and Professional Wayfinding Solutions