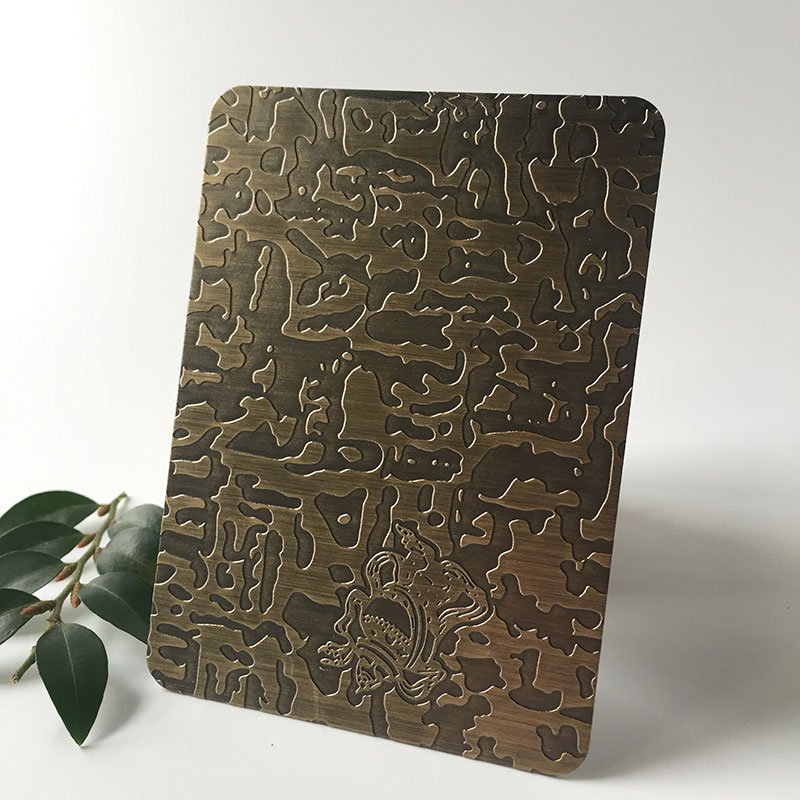

Antique Finish Stainless Steel Sheet

Table of Contents

Explore the beauty of stainless steel through our antique finish treatment process. We specialize in enhancing stainless steel sheets with a unique touch, adding durability and aesthetic appeal to various applications.

Innovative Surface Treatment

Discover the art of stainless steel plate paint surface treatment at JYF METAL. Our advanced processes bring out the best in stainless steel, offering corrosion resistance, improved wear resistance, enhanced electrical conductivity, reflectivity, and overall beauty.

Copper Plating Excellence

JYF METAL excels in stainless steel copper plating, employing cutting-edge techniques for exceptional results. We utilize two primary methods: vacuum plating and stainless steel plating. Vacuum plating involves electrolysis, forming a protective metal film on the surface. On the other hand, stainless steel plating uses a chemical reduction reaction in a water solution, creating a continuous metal coating through autocatalysis.

Precision in Processing

Our meticulous processing ensures quality outcomes. We initiate the process by thoroughly removing wax and oil from the parts to be plated. After activation, alkaline copper is plated for approximately 10 minutes. The subsequent steps include washing, neutralizing, and activating. Plating continues for over 20 minutes until the coating is sufficiently thick. The workpiece undergoes washing, activation, direct plating of nickel and black color. Plating time is adjusted to achieve a uniform black surface. Subsequently, the workpiece is washed, dried, and prepared for further processing.

Artistic Finishing Touch

For a unique touch, the copper-bright plated workpiece can undergo blackening treatment. We use a 5% potassium sulfide solution for soaking, achieving a black or brown appearance. The product is carefully washed, dried, and ready for the next steps. The final touch involves polishing the custom product with a nylon wheel, adjusting the degree of polishing based on the desired antique effect. Once the workpiece reaches the desired effect, we apply an electroplating varnish, providing a fingerprint-free finish. The workpiece is then dried and expertly packaged.

Diverse Copper Colors

Explore a spectrum of copper colors, including bronze, antiqued bronze, red copper, and brass. Our copper-plated materials encompass iron, aluminum, and stainless steel. Stainless steel antique copper, a popular decorative material, undergoes special processing, creating an aged, retro appearance. Widely used in diverse fields such as bronze doors, decorations, carvings, retro furniture fittings, study essentials, antiques, handicrafts, incense burners, handles, reliefs, display cabinets, curtain walls, and sculptures, our stainless steel antique copper receives acclaim and appreciation from our valued customers.

Advantages of Stainless Steel Antique Copper Finish

Embrace the advantages of using stainless steel antique copper. The cost-effective production and processing of stainless steel antique copper provide a significant price competitive edge compared to traditional copper. Stainless steel’s higher hardness allows for more extensive use, surpassing the limitations of copper. Additionally, stainless steel’s superior chemical properties ensure corrosion resistance, wear resistance, waterproofing, and rust-proofing, leading to an extended service life. Choose JYF METAL for exceptional quality and innovation in stainless steel plate treatments.

You Might Also Like

Please Share This

Recent Posts

- Custom Metal Fabrication for Hospitality Projects

- Decorative Stainless Steel Elements in Hospitality Architecture

- Stainless Steel Applications in High-End Residential Apartments

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Metal Sculpting and Structural Stability: Exploring Stainless Steel Designs