Laser Cut Metal Screen: Redefining Modern Space with Precision and Style

Table of Contents

With increasingly demanding spaces for both function and visual character, laser cut metal screens have become an indispensable architectural and decorative element in modern design. These screens achieve a refined balance of strength, elegance, privacy, and openness by combining advanced technology in laser cutting with durable metals.

From residential interiors to large-scale commercial projects, laser cut metal screens offer flexible solutions for dividing spaces and enhancing visuals, all while ensuring long-term performance and design freedom. Their ability to merge engineering precision with artistic expression has made them a preferred choice for designers, architects, and developers worldwide.

What Is a Laser Cut Metal Screen

First and foremost, it is necessary to explain what a laser cut metal screen is and how it is made before really being able to understand its applications and overall value. It helps set a base for why laser cut metal screens have become such a widely adopted architectural element across industries and design styles, from modern minimalism to luxury commercial interiors.

Definition and Core Structure

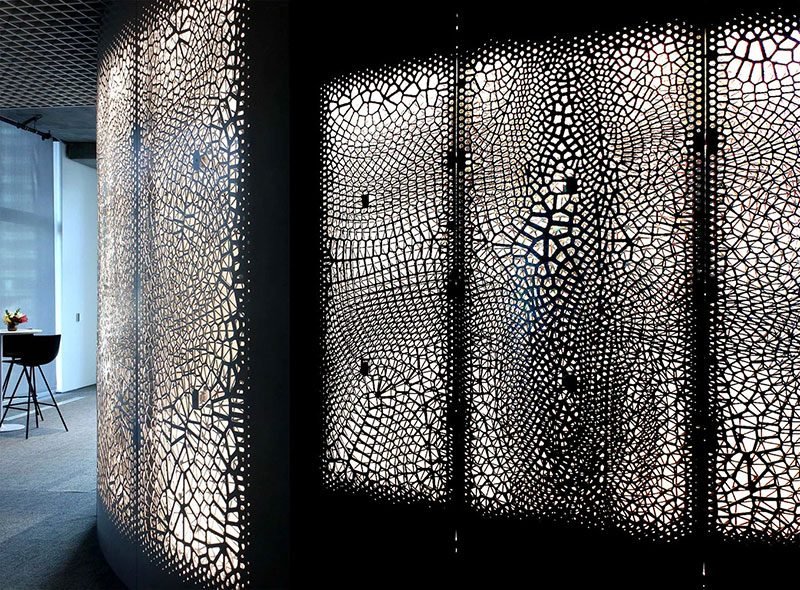

A laser cut metal screen is made by using high-precision laser technology to cut intricate patterns into sheets of metal, usually made of aluminum, stainless steel, or weather-resistant steel. This produces a panel that combines high structural strength with fine artistic detailing. While solid partitions prevent the entrance of natural light and air, this openwork structure allows both to pass through while creating clear spatial separation. It is this unique structure that makes laser-cut metal screens a functional building component and decorative design feature within the same form.

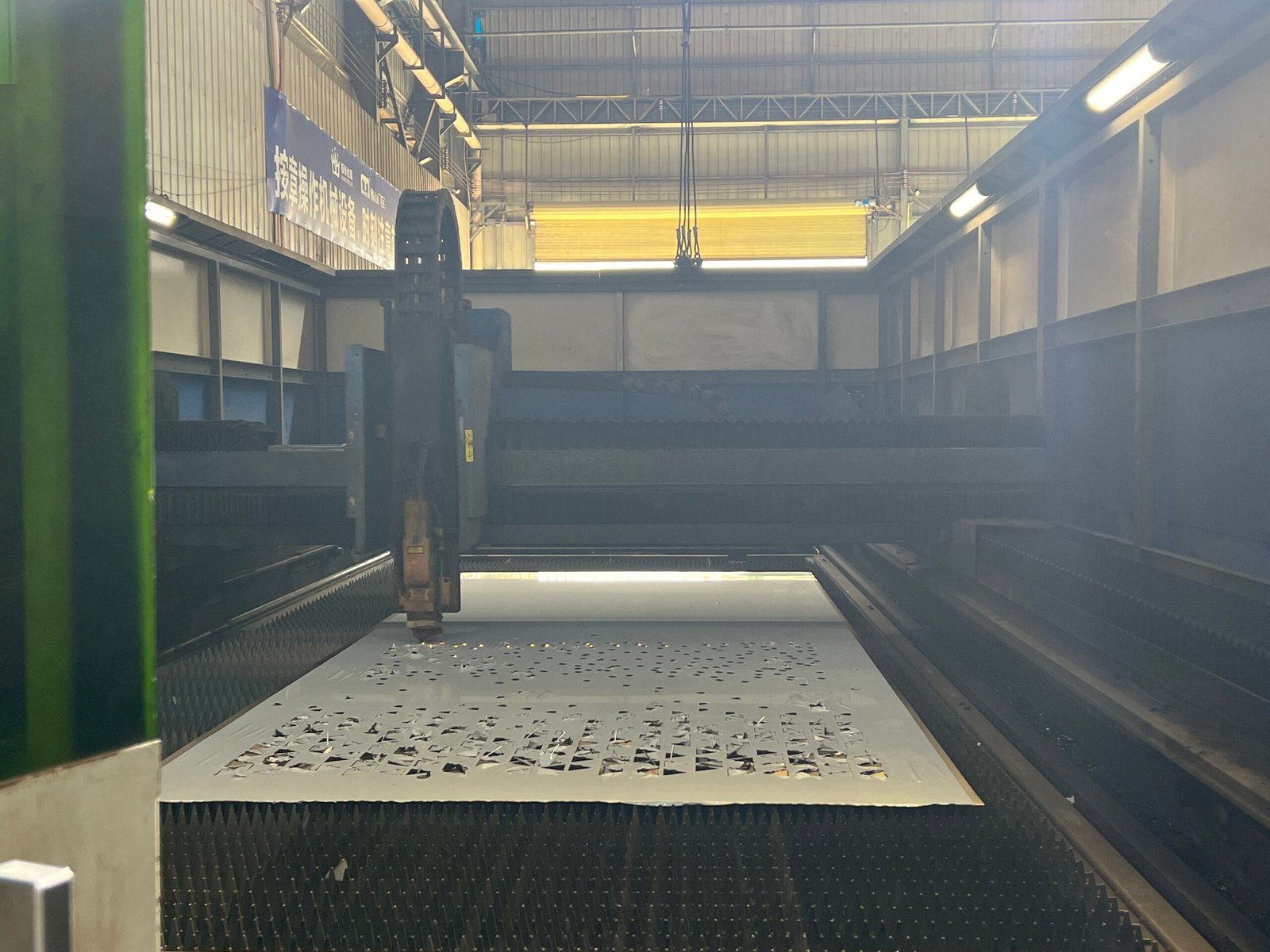

The Role of Laser Cutting Technology

Laser cutting ensures that the patterns are consistently of very high accuracy, with smooth edges and the highest quality across every panel produced. This technology allows for complex and delicate designs that cannot be achieved by traditional mechanical cutting methods. It also supports efficient mass customization, enabling unique designs for individual projects without compromising production stability or quality consistency. As a result, designers are given more creative freedom while maintaining the highest standards of fabrication.

Key Advantages of Laser Cut Metal Screens

It is the combination of functional strength and aesthetic performance that has influenced the rise in popularity of laser-cut metal screens. These screens provide a powerful mix of durability, visual elegance, and long-term cost efficiency compared to traditional partitions and decorative materials, making them suitable for applications ranging from short-term projects to permanent architectural installations.

High Strength and Long-Term Durability

Metal materials boast superior mechanical strength and high resistance to deformation under normal use and environmental stress. With powder coating, anodizing, or PVD coating, laser cut metal screens can effectively resist corrosion, moisture, heat, and ultraviolet exposure. This makes them suitable for both indoor and outdoor environments-even in regions of the world where there is high humidity, strong sunlight, or widely fluctuating temperatures. Their structural reliability ensures consistent performance throughout many years of use.

A Balanced Solution for Privacy and Openness

Laser-cut metal room dividers separate spaces without completely enclosing them, keeping the interiors visually connected and comfortable. The perforated design keeps the airflow smooth and maintains natural lighting while allowing controlled privacy. This balance is particularly valuable in open-plan interiors, offices, restaurants, and hospitality environments, where both separation and spatial continuity are needed. The result is a space that feels organized and private without becoming closed or restrictive.

Low Maintenance and Cost Efficiency

Being made of metal, screens require minimal maintenance compared to wood, glass, or fabric partitions throughout their service life. They are easy to clean and do not absorb moisture or odors; they are less susceptible to aging, warping, or surface damage. Therefore, laser cut metal screens become not only an aesthetic but also a very financially practical long-term investment due to their long service life.

Major Application Scenarios for Laser Cut Metal Screens

With the structural flexibility and strong decorative impact, laser cut metal screens can fit into a wide range of room types. Their versatility also allows designers to employ them in various residential, commercial, and public spaces for functional separation or artistic embellishment.

Residential Interior and Exterior Spaces

Laser-cut metal screens are widely used in residences for living room dividers, entrance partitions, stair guards, balcony privacy panels, and decorative wall features. They are used to differentiate various zones within an open living configuration without disturbing the flow of natural light. Outdoor applications for these panels include garden screens, patio partitions, terrace enclosures, and sun-shading elements that can provide needed shade while maintaining ventilation and preserving views to surrounding landscapes. The durability ensures reliable performance under long-term outdoor exposure.

Commercial and Hospitality Environments

Laser-cut metal screens are commonly used in hotels, restaurants, offices, retail stores, and exhibition halls for zoning, circulation guidance, concealing service areas, and enhancing brand atmosphere. Depending on the custom pattern and finish, they are able to represent corporate identity and interior and branding themes while still providing a modern, open visual feel. Their robustness and low maintenance, in turn, make them quite suitable for high-traffic commercial use.

Architectural Facades and Landscape Design

Laser-cut metal screens are increasingly used as part of building facades for sun-shading systems, balcony enclosures, and protective barriers. In landscape design, they function as artistic backdrops, decorative fencing, garden partitions, and privacy walls. The interaction of sunlight with the perforated patterns creates dynamic shadow effects that change according to the time of day, enhancing architectural depth and visual movement within urban and natural environments.

Customization and Design Flexibility of Laser Cut Metal Screens

One of the strongest reasons designers like laser cut metal screens is the virtually unlimited customization they provide. From visual style to structural performance, nearly every detail can be tailored to meet a particular project’s requirements and architectural intentions.

Unlimited Pattern Design Options

Patterns vary from minimalistic geometrical shapes to intricate floral motifs, abstract art, cultural symbols, and even designs that are fully customized with graphics or logos. Designers can precisely specify pattern density to adjust visibility, shading, and light transmission to suit functional needs. This flexibility allows laser cut metal screens to adapt to various architectural styles with ease, from subtle elegance to bold visual impact.

Material Choices and Surface Treatments

Common materials include lightweight aluminum, luxurious stainless steel, and industrial-style weathering steel-all with distinct visual and performance characteristics. Rich color and texture options are available with surface finishes such as powder coating, brushing, sandblasting, polishing, and PVD coating to enhance durability and aesthetic appeal. These finishing processes also provide improved resistance to scratches, corrosion, and environmental wear.

Structural Size, Thickness, and Installation Methods

Laser-cut metal screens can be fabricated in a wide range of sizes and thicknesses dependent on load-bearing and safety requirements. Installation methods include wall-mounted, floor-standing, suspended, framed, or fully integrated into railings and facades. It is this structural flexibility that ensures their compatibility with the many different architectural conditions, while safety, stability, and long performance are maintained.

Important Factors to Consider When Selecting a Laser Cut Metal Screen

While laser-cut metal screens do provide really good flexibility in application, the right solution must be carefully evaluated on technical, environmental, and aesthetic bases. Proper planning at the design stage ensures long performance, safety, and visual harmony upon installation.

Environmental Conditions and Material Suitability

Outdoor installations need to be highly resistant to corrosion and have strong structural stability under continuous exposure to changing weather conditions, but for indoor projects, aesthetic refinement and light weight can prevail. Proper metal type and surface finish selection determine a long service life, particularly in coastal, high-humidity, or high-temperature areas where environmental stress is significantly greater.

Privacy Level and Pattern Density

Pattern openness has a direct impact on privacy, airflow, and lighting performance within any architectural environment. High-density patterns give stronger visual shielding and a greater sense of enclosure, while more open designs enhance ventilation and visual transparency. The balance should always be determined by the specific functional requirements of the space, including how much separation, brightness, and light control is ultimately needed for comfort.

Visual Coordination with the Overall Space

The color, texture, and pattern of the screen must harmonize with surrounding architecture, furniture, lighting, and the overall design theme for visual consistency. A well-designed laser cut metal screen should enhance the space naturally without overpowering it, acting as both a functional divider and a refined decorative focal point that strengthens the overall spatial character.

Conclusion

Laser cut metal screens combine advanced manufacturing technology with durable materials and artistic design, offering an ideal solution for modern space division and decoration. They provide strength without heaviness, privacy without isolation, and elegance without excessive maintenance. Whether used in residential interiors, outdoor landscapes, commercial environments, or architectural facades, laser cut metal screens continue to redefine how spaces are shaped and experienced.

By choosing a high-quality laser cut metal screen solution tailored to your project, you can achieve the perfect balance of durability, design, and functionality—explore more professional options and customization possibilities on this website JYF METAL.

You Might Also Like

Please Share This

Recent Posts

- Custom Metal Fabrication for Hospitality Projects

- Decorative Stainless Steel Elements in Hospitality Architecture

- Stainless Steel Applications in High-End Residential Apartments

- Stainless Steel Color Panels in Hotel Projects: Applications and Design Insights

- Metal Sculpting and Structural Stability: Exploring Stainless Steel Designs