Stainless Steel Decorative Sheet

Stainless Steel Decorative Sheet

Stainless steel color plates can achieve different color effects through chemical reactions or physical methods, which can meet different design requirements. Its surface is smooth, brightly colored, and has a metallic texture, which can add a unique sense of modernity and fashion to the building. At the same time, the stainless steel color plate also has the characteristics of strong plasticity. It can realize various shapes and curves through bending, stretching and other processing processes, adding more Elements of art to the building.

Type Of Stainless Steel Decorative Sheet

As a building material with engineering, design and use advantages, stainless steel color plate can not only meet the needs of the project, but also add aesthetic and Elements of art to the building. Its corrosion resistance, easy cleaning, and environmental sustainability make it an important choice in modern architecture.

Stainless Steel Mirror Polished Sheet

201/304/316 stainless steel mirror polished sheet is the most common in decorative sheet metal. The mirror finish decorative sheet is polished with abrasive liquid through polishing equipment on stainless steel 2B plate surface. To remove the surface oxidation layer to achieve the mirror effect (divided into different grades according to the requirements......

More Details

Stainless Steel Hairline Sheet

201/304/316 stainless steel hairline metal sheet, also known as Satin, snowflake sand, NO, 4, cross-drawing, and so on. Brushed stainless steel sheet is the use of stainless steel 2B plate or sheet metal through equipment and an abrasive belt in the surface grinding, removing the oxide layer on the surface so that the surface forms a silk texture......

More Details

Stainless Steel Sandblasted Sheet

201/304/316 stainless steel sandblasted metal sheet, whose surface effect is through the equipment to hit the sand particles on the stainless steel surface. The surface appears to form the surface granular sand surface, which can be thick or thin, dense or spare. After processing, the stainless steel sheet metal surface will be uniform, have a fine texture......

More Details

Stainless Steel Vibration Sheet

Stainless steel vibration sheet can be SS201/ SS304/ SS316, is through the device on the grinding wheel regularly rotating to form a texture. Sheet metal and special-shaped parts also need to be completed by hand. The surface of the product can be through bending and overlapping texture display. The finished surface has a strong sense of art......

More Details

Stainless Steel Etched Sheet

Stainless steel etching usually uses SS304 or SS316, or copper plate, this process is in accordance with the design drawings and requirements, through a combination of chemical solution and equipment, on the surface of stainless steel or copper corrosion, formed in a pattern, a variety of designs. It can be etched on a brushed surface, mirror surface, or copper plate.......

More Details

Stainless Steel Embossed Sheet

Stainless steel embossing sheet is formed by pressing the surface of the steel plate with the equipment and the die. According to the project processing needs, the material can be SS201/ SS304/ SS316, and the surface can be a hairline finish, mirror finish, sandblasting, and other surfaces. After all the surface treatment, re-processing patterns......

More Details

Stainless Steel Copper Sheet

Stainless steel imitation copper antique sheet is through equipment electrolytic plating, natural copper base color, make a variety of similar copper colors, and then hairline and anti-fingerprint process so that the stainless steel surface achieves real copper and antique (imitation old) effect. In addition, the plate surface can be etched with a variety of patterns......

More Details

Stainless Steel Water Ripple Sheet

Metal water ripple stainless steel sheet belongs to the main product in the decoration metope and is the famous representative of the decoration design industry. The corrugated shape makes the surface have a fine concave and convex sense. It uses 8k mirror stainless steel reflective characteristics, and the pattern is similar to water ripples......

More Details

Surface Introduction

In modern architectural decoration, metal material is a new trend of technical aesthetics with permanent vitality. Metal engineering materials include steel, stainless steel, aluminum, copper, alloy materials, etc. Widely applied in construction engineering, metals have different properties such as density, corrosion resistance, tensile strength, plasticity, and so on. With rich experience in metal surface treatment and manufacturing, JYF Metal will serve you with sincerity and professionalism.

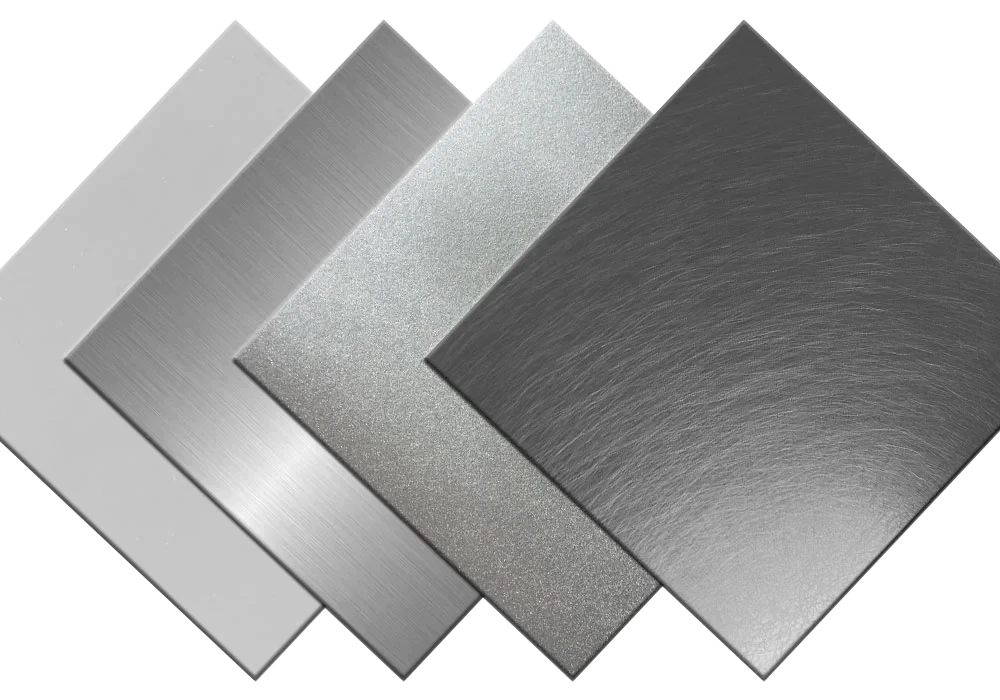

Surface Finish

The surface of metal sheets and products is treated by mechanical, physical, and chemical methods. Surface treatment varies in different properties.

- Mirror

- Brushed

- Sandblasted

- Anti fingerprints

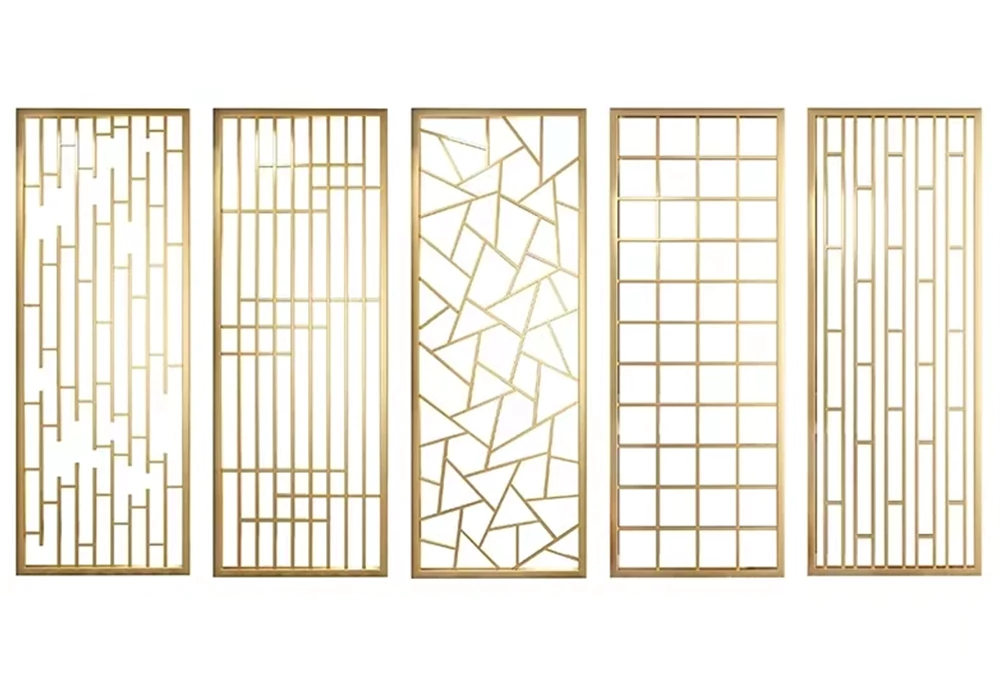

Attractive Pattern

Metal sheets and products can be designed and produced with various personalized patterns and patterns to meet designers' and architects' inspiration and space art.

- Engraving

- Hollowing

- Etching

- Embossing

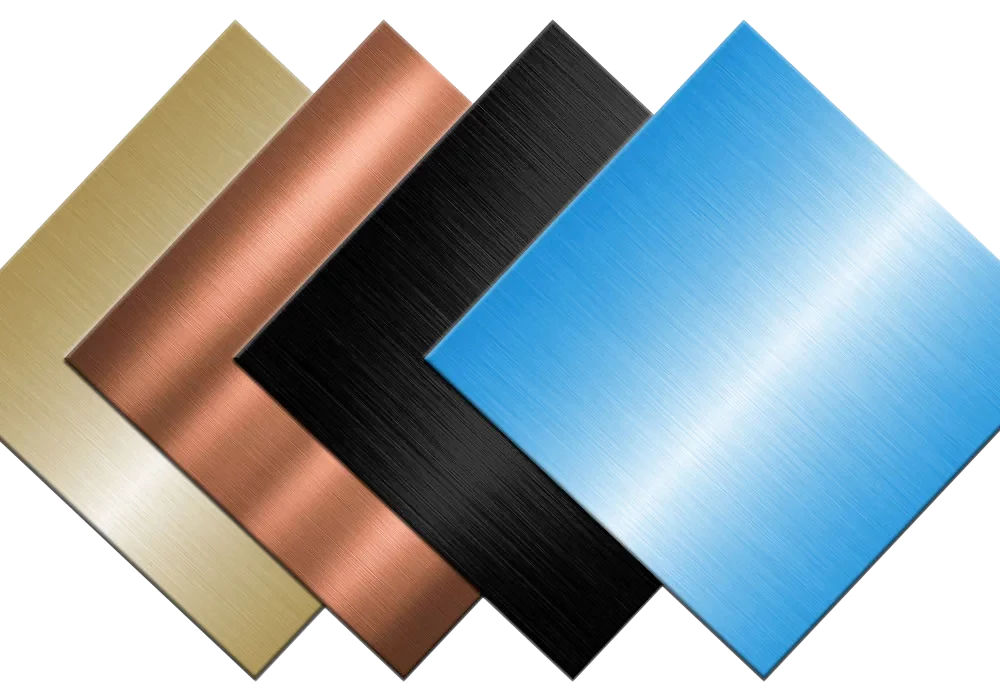

Fashion Color

According to metal characteristics and designs, various colors can be provided for your reference after completing the metal sheets and products to create a bright scene and a sense of the times.

- PVD Coating

- Electronic Coating

- Oxidation

- Spraying

Metal Molding

The metal material can process the perfect bending arc or the curved surface, the wave type, and so on, according to the design draft and the metal characteristic.

- Stamping

- Hammering

- Rolling

- Welding